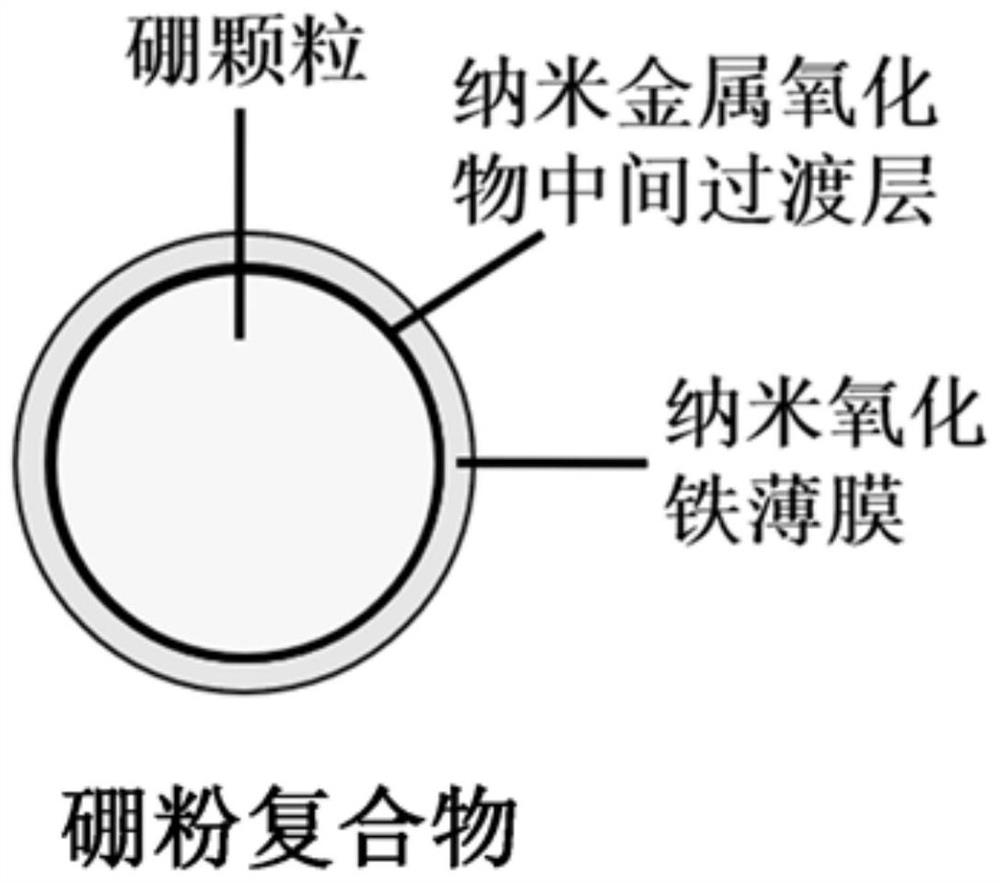

Boron powder compound with high combustion performance and preparation method thereof

A combustion performance and composite technology, applied in the direction of nuclear power generation, climate sustainability, explosives, etc., can solve the problems of boron powder energy density loss, difficult to adjust the thickness of the cladding layer, poor integrity, uniformity, etc., to achieve energy The effects of improved release efficiency, easy implementation and promotion, and high quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

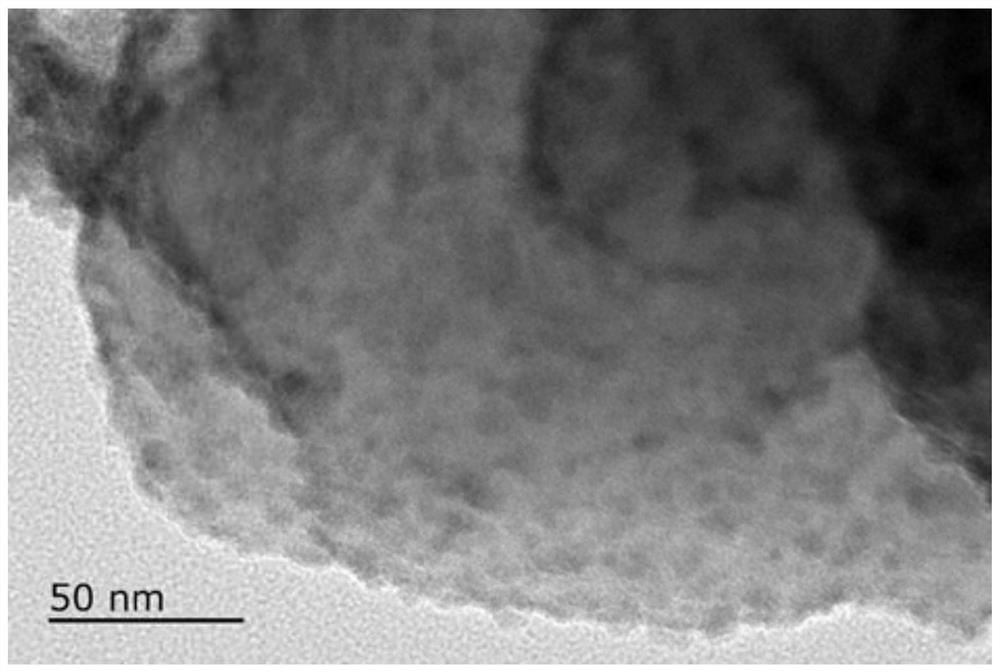

[0051] This embodiment provides a boron powder composite with high combustion performance and a preparation method thereof. The intermediate transition layer is zinc oxide, and the two precursors used in the synthesis of the intermediate transition layer zinc oxide by ALD are diethyl zinc and water, respectively. The two precursors used in the synthesis of iron oxide films by ALD are ferrocene and oxygen, respectively, and the type of reaction chamber of the atomic layer deposition system used is a fixed bed type. The method specifically includes the following steps:

[0052] Step 1. With boron particles as the inner core, the boron particles are placed in the reaction chamber of the atomic layer deposition system, and the pressure in the reaction chamber is controlled to be negative pressure, 200Pa, and the temperature is 130°C;

[0053] Step 2, using zinc oxide as the intermediate transition layer, performing several atomic layer deposition cycles on the surface of the boron ...

Embodiment 2

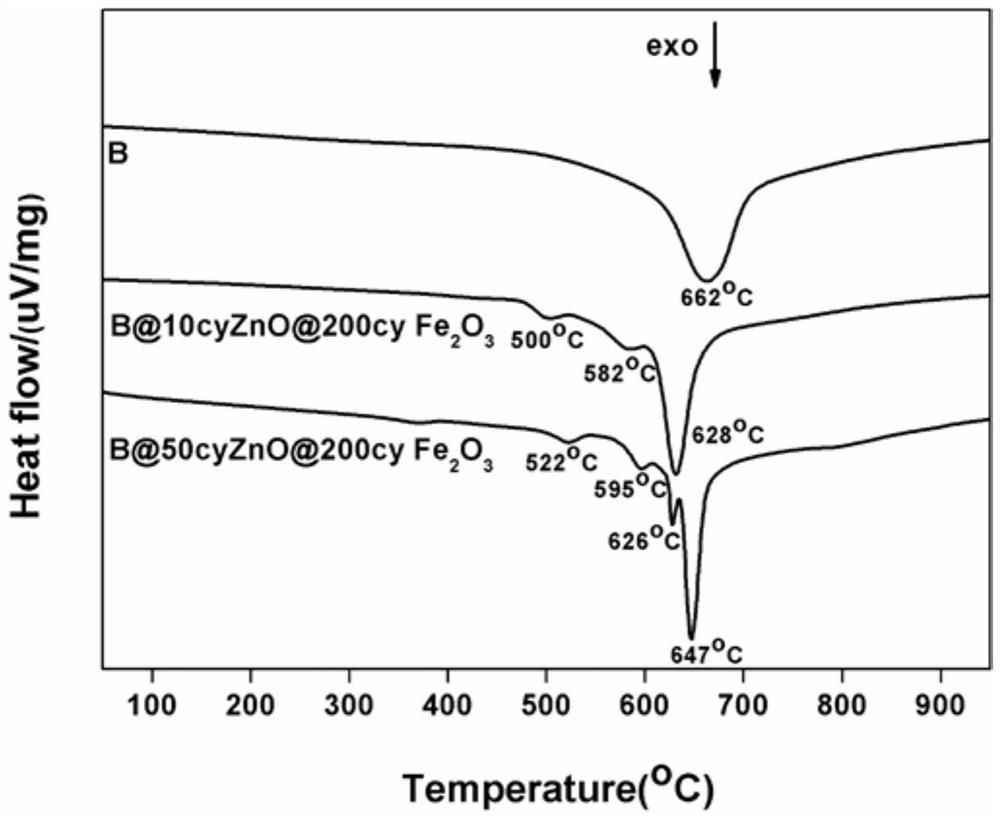

[0070] This embodiment provides a boron powder composite with high combustion performance and a preparation method thereof. This method is the same as Example 1, the only difference is that in this example, steps 2.1 to 2.4 are cycled 50 times to finally obtain a composite boron fuel coated with a zinc oxide transition layer that is cycled 50 times and an iron oxide film that is cycled 200 times. i.e. B@50cyZnO@200cyFe 2 O 3 .

[0071] figure 2 The DSC test results show that, compared with the uncoated modified boron fuel, after 50 cycles of the zinc oxide transition layer and 200 cycles of the iron oxide film ALD-coated modified boron powder composite, at 522 °C and 595 °C An obvious exothermic shoulder peak of the reaction between boron and zinc oxide was found at 626 °C, an obvious exothermic shoulder peak of the aluminothermic reaction of boron and iron oxide films was found at 626 °C, and an exothermic shoulder peak of the rapid reaction between boron and oxygen was f...

Embodiment 3

[0073] This embodiment provides a boron powder composite with high combustion performance and a preparation method thereof. This method is the same as Example 1, the only difference is that: the type of reaction chamber of the atomic layer deposition system used in this example is a rotating bed type, the intermediate transition layer used is titanium oxide, and the first precursor is tetraisopropanol Titanium, the second precursor is hydrogen peroxide;

[0074] The temperature in step 1 is 150°C, and the time sequence in step 2 is 60s from t1 to t4; steps 2.1 to 2.4 are cycled 20 times; steps 3.1 to 3.4 are cycled 250 times, and finally a transition layer coated with 20-cycle titanium oxide is obtained and the composite boron fuel with 250 cycles of iron oxide films, namely B@20cyTiO 2 @250cyFe 2 O 3 .

[0075] Figure 5 The DSC test results show that, compared with the uncoated modified boron fuel, after 20 cycles of titanium oxide transition layer and 250 cycles of iro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com