Preparation method and application of marine fish oligopeptide capable of resisting fatigue and reducing uric acid

An oligopeptide, marine technology, applied in the biological field, can solve the problem of low development and utilization of marine fish protein, and achieve the effect of promoting high-value utilization, reducing uric acid generation and small molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

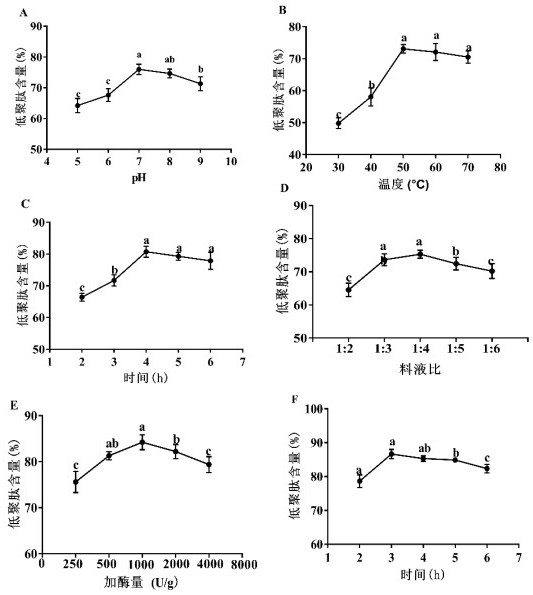

[0049] Example 1. Preparation and evaluation of Far Eastern sardine enzymolysate

[0050] (1) Preparation of Enzymatic Hydrolysate of Pseudo-Sardines from the Far East

[0051] Autolytic enzymolysis process: using fresh Far Eastern sardines ( Sardinops sagax ) (purchased from Guangdong Xingyi Marine Biological Engineering Co., Ltd.) as raw materials, remove the internal organs, scales and gills, harvest the meat, and grind it into surimi. Accurately weigh 500.00g of surimi, add distilled water at a ratio of 1:2 (g / mL) to liquid, homogenize, adjust pH to 6, temperature at 50 °C, and enzymatic hydrolysis for 3 h. Then, the enzyme was inactivated in a boiling water bath at 100 °C for 15 min, cooled, centrifuged at 4 °C, 8000 r / min for 20 min, and the supernatant was decolorized with activated carbon for 30 min to obtain the Far Eastern sardine enzymatic hydrolysate ( Sardinops sagax hydrolysate, SSH).

[0052] Enzymatic hydrolysis process of exogenous enzymes: Accurately we...

Embodiment 2

[0095] Embodiment 2, the preparation of flat rudder bonito enzymolysate

[0096] (1) Preparation and evaluation of the enzymatic hydrolyzate of bonito flakes

[0097] Autolytic enzymatic hydrolysis process: Using fresh flat rudder bonito (purchased from Guangdong Xingyi Marine Bioengineering Co., Ltd.) as raw material, remove the internal organs, scales and gills, harvest the meat, and grind it into surimi. Accurately weigh 500.00 g of surimi, add distilled water according to the ratio of material to liquid 1:3 (W:V, g / mL), homogenize, adjust the pH to 7, the temperature is 60 ° C, and enzymatic hydrolysis for 4 h. Then, the enzyme was inactivated in a boiling water bath at 100 °C for 15 min, cooled, centrifuged at 4 °C, 8000 r / min for 20 min to obtain the supernatant, and the supernatant was decolorized with activated carbon for 30 min to obtain the enzymatic hydrolyzate of bonito flakes ( Auxis thazard hydrolysate, ATH).

[0098]Exogenous enzyme enzymolysis process: Accur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com