Scylla paramamosain soft granule compound feed with long shelf life and preparation method of scylla paramamosain soft granule compound feed

A technology of mud crab and compound feed, which is applied in the field of mud crab soft granule compound feed and its preparation, can solve the problems of accelerating fat oxidation and rancidity, increasing the amount of antioxidants used, etc., to improve stability in water, reduce The effect of collapsing and prolonging the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Taking the production of 100 kg of cylindrical mud crab soft pellet feed with a diameter of 2 mm as an example, the following steps are included:

[0032] First, mix 25 kg of fish meal, 23 kg of soybean protein powder, 5 kg of shrimp shell powder, 7 kg of wheat bran, 3 kg of yeast powder, 2 kg of serum powder, 7 kg of dried snail meat powder, 3 kg of Scallop powder, 10 kg of alpha-corn starch, 1 kg of cholesterol, 3 kg of choline chloride, 1 kg of calcium dihydrogen phosphate, 3 kg of multivitamins, 1 kg of sodium carboxymethyl cellulose are crushed and mixed well ; Then mix with 1 kg of krill oil and 4 kg of well-prepared oil (1 kg of krill oil, 2 kg of corn oil and 1 kg of coconut oil), add 1 kg of vegetable mixture; finally put it in the mixer, gradually add Mix 30-45% water evenly, use a 2mm granulating die, and extrude it into soft granules through high temperature and high pressure. When it is cooled and air-dried to about 20% moisture, it is vacuum-packed and sto...

Embodiment 2

[0035] Taking the production of 100 kg of cylindrical mud crab soft pellet feed with a diameter of 3 mm as an example, the following steps are included:

[0036]First, 30 kg of fish meal, 18 kg of soybean protein powder, 8 kg of shrimp shell powder, 4 kg of wheat bran, 2 kg of yeast powder, 3 kg of serum powder, 4 kg of dried snail meat powder, 5 kg of Dried scallop powder, 10 kg of alpha-corn starch, 2 kg of cholesterol, 1 kg of choline chloride, 3 kg of calcium dihydrogen phosphate, 1 kg of multivitamin, 2 kg of sodium carboxymethyl cellulose are pulverized and mixed well ; Then mix well with 0.5 kg of krill oil and 6 kg of well-prepared oil (3 kg of krill oil, 1 kg of corn oil and 2 kg of coconut oil), add 0.5 kg of vegetable mixture; finally put it in the mixer, gradually add Mix 30-45% of water evenly, use a 3mm granulating die, extrude it into soft granules by high temperature and high pressure, when it is cooled and air-dried to about 30% moisture, vacuum package, and s...

Embodiment 3

[0039] Taking the production of 100 kg of cylindrical mud crab soft pellet feed with a diameter of 5 mm as an example, by designing different plant mixture formulas, the shelf life of the soft pellet feed prepared by each formula was compared.

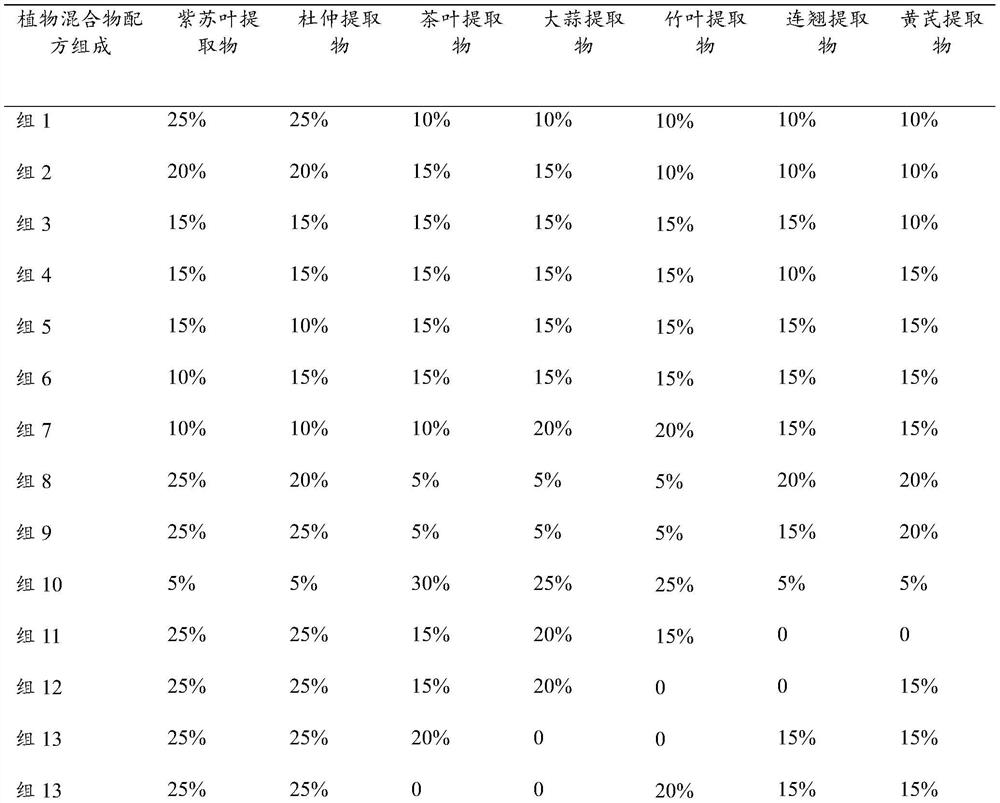

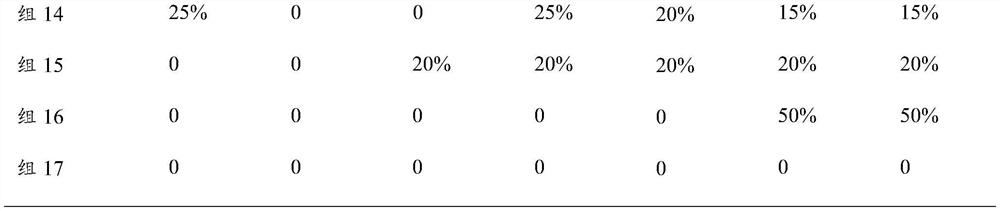

[0040] First, 28 kg of fish meal, 20 kg of soybean protein powder, 5 kg of shrimp shell powder, 5 kg of wheat bran, 5 kg of yeast powder, 3.5 kg of serum powder, 3 kg of dried snail meat powder, 2 kg of Dried scallop powder, 14.3 kg of alpha-corn starch, 1 kg of cholesterol, 0.7 kg of choline chloride, 1.5 kg of calcium dihydrogen phosphate, 2 kg of multivitamin, 2 kg of sodium carboxymethyl cellulose are pulverized and mixed well ; Then mix well with 2 kg of krill oil and 4 kg of prepared oil (2 kg of krill oil, 1 kg of corn oil and 1 kg of coconut oil), and divide the mixture into 17 equal parts; The formulas of different plant mixtures were added to it, as shown in Table 1 below. Among them, group 17 did not add the plant mixture, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com