Long-acting anti-fouling fabric and preparation method thereof

A fabric, long-term technology, applied in the field of fabrics, can solve problems such as diver injury, diving suit rupture, affecting the service life of diving suit, etc., to achieve excellent anti-fouling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

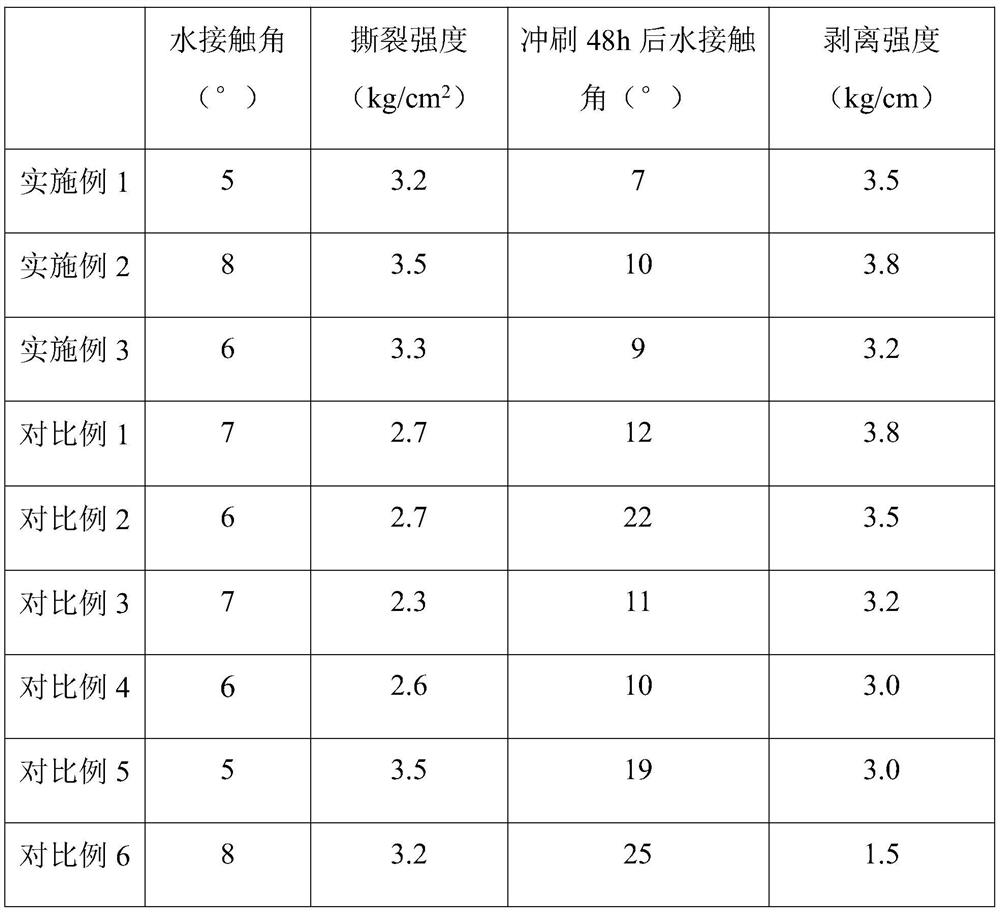

Examples

Embodiment 1

[0031](1) The preparation method of carboxymethyl-cyclodextrin is: mix cyclodextrin, sodium hydroxide and deionized water in a mass ratio of 4.2:3.5:18, stir until dissolved, and add chlorine with 1.8 times the mass of cyclodextrin. Sodium acetate was stirred at 30 rpm for 3 hours, cooled to room temperature, adjusted to pH 4.8 with hydrochloric acid, and precipitated by adding methanol with 5 times the mass of cyclodextrin, filtered after precipitation, and dried in a vacuum drying oven at 80 °C Constant weight to obtain carboxymethyl-cyclodextrin;

[0032] (2) Disperse carboxymethyl-cyclodextrin in deionized water with 8 times the mass of carboxymethyl-cyclodextrin, and dropwise add 0.1 mass of carboxymethyl-cyclodextrin at a rate of 3 ml / min at 10 rpm times the mass fraction of 3-5% sodium hydroxide solution, continue to stir and dropwise add 0.45 times the mass of carboxymethyl-cyclodextrin with a mass fraction of 10% p-toluenesulfonyl chloride at a rate of 3-5ml / min. The...

Embodiment 2

[0038] (1) The preparation method of carboxymethyl-cyclodextrin is: mix cyclodextrin, sodium hydroxide and deionized water in a mass ratio of 4.4:3.5:19, stir until dissolved, and add chlorine with 1.9 times the mass of cyclodextrin. Sodium acetate was stirred and reacted at 40 rpm for 4 h, cooled to room temperature, adjusted to pH 4.9 with hydrochloric acid, and precipitated by adding methanol with 6 times the mass of cyclodextrin, filtered after precipitation, and dried in a vacuum drying oven at 85 °C Constant weight to obtain carboxymethyl-cyclodextrin;

[0039] (2) Disperse carboxymethyl-cyclodextrin in deionized water with 9 times the mass of carboxymethyl-cyclodextrin, and at 15 rpm, dropwise add 0.13 carboxymethyl-cyclodextrin mass at a rate of 4 ml / min times the sodium hydroxide solution with a mass fraction of 4%, continue to stir and dropwise add 0.48 times the mass of carboxymethyl-cyclodextrin with a mass fraction of 15% of the acetonitrile solution of p-toluenes...

Embodiment 3

[0045] (1) The preparation method of carboxymethyl-cyclodextrin is as follows: mix cyclodextrin, sodium hydroxide and deionized water in a mass ratio of 4.5:3.6:20, stir until dissolved, and add chlorine with twice the mass of cyclodextrin. Sodium acetate was stirred at 50 rpm for 5 h, cooled to room temperature, adjusted to pH 5 with hydrochloric acid, and precipitated by adding methanol with 8 times the mass of cyclodextrin, filtered after precipitation, and dried in a 90°C vacuum drying oven until Constant weight to prepare carboxymethyl-cyclodextrin

[0046] (2) Disperse carboxymethyl-cyclodextrin in deionized water with 10 times the mass of carboxymethyl-cyclodextrin, and dropwise add carboxymethyl-cyclodextrin at a rate of 5 ml / min at 10-20 rpm 0.15 times the mass of sodium hydroxide solution with a mass fraction of 5%, continue to stir and dropwise add 0.5 times the mass of carboxymethyl-cyclodextrin with a mass fraction of 20% acetonitrile solution of p-toluenesulfonyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com