Nitrogen-doped porous carbon sphere/S composite material, preparation method thereof and application of nitrogen-doped porous carbon sphere/S composite material in lithium-sulfur battery

A nitrogen-doped porous carbon and composite material technology, which is applied in lithium batteries, carbon preparation/purification, battery electrodes, etc., can solve the problems of poor conductivity of active materials, achieve excellent conductivity, strong chemical and physical adsorption capacity, The effect of high electrical contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

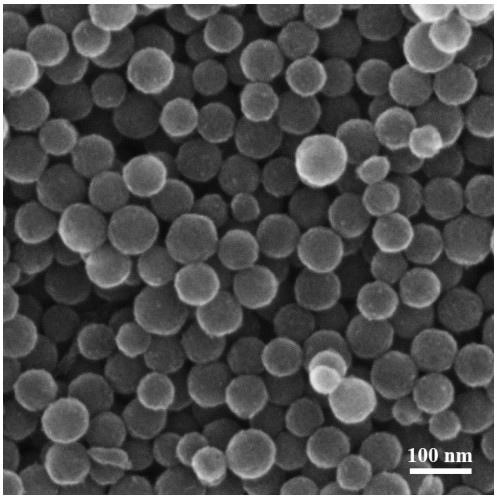

[0047] Step 1: Preparation of nitrogen-doped porous carbon spheres for lithium-sulfur battery cathode sulfur carrier

[0048] (1) take by weighing an appropriate amount of zinc nitrate hexahydrate and add it to deionized water, configure the zinc nitrate aqueous solution of 0.012 mol / L to obtain A solution;

[0049] (2) Weigh an appropriate amount of 2-methylimidazole and add it to deionized water, configure 0.12 mol / L of 2-methylimidazole aqueous solution to obtain B solution;

[0050] (3) Mix the A solution with the B solution, control the temperature of the reaction solution to be 10°C, and stir the reaction for 3h;

[0051] (4) transferring the reaction solution obtained in step (3) into a centrifuge tube, using a centrifuge at 7000 rpm / min to separate the solid-phase product, washing with deionized water, and freeze-drying to obtain a white powder;

[0052] (5) The white powder of step (4) is placed in a quartz boat, and carbonized at 900° C. under a nitrogen atmosphere ...

Embodiment 2

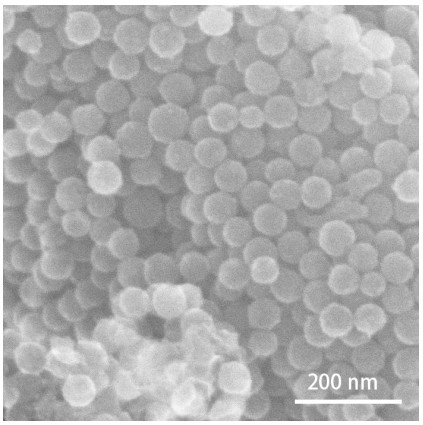

[0062] Step 1: Preparation of nitrogen-doped porous carbon spheres for lithium-sulfur battery cathode sulfur carrier

[0063] (1) take by weighing an appropriate amount of zinc nitrate hexahydrate and add it to deionized water, configure the zinc nitrate aqueous solution of 0.012 mol / L to obtain A solution;

[0064] (2) Weigh an appropriate amount of 2-methylimidazole and add it to deionized water, configure 0.12 mol / L of 2-methylimidazole aqueous solution to obtain B solution;

[0065] (3) Mix the A solution with the B solution, control the temperature of the reaction solution to be 20°C, and stir the reaction for 3h;

[0066] (4) transferring the reaction solution obtained in step (3) into a centrifuge tube, using a centrifuge at 7000 rpm / min to separate the solid-phase product, washing with deionized water, and freeze-drying to obtain a white powder;

[0067] (5) The white powder of step (4) is placed in a quartz boat, and carbonized at 900° C. under a nitrogen atmosphere ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com