Preparation method of bio-based UV curing initiator as well as product and application of bio-based UV curing initiator

A curing initiator, bio-based technology, applied in application, organic chemistry, household appliances, etc., can solve the problems of limited application, poor solubility, etc., and achieve the effect of high initiator activity, good compatibility, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

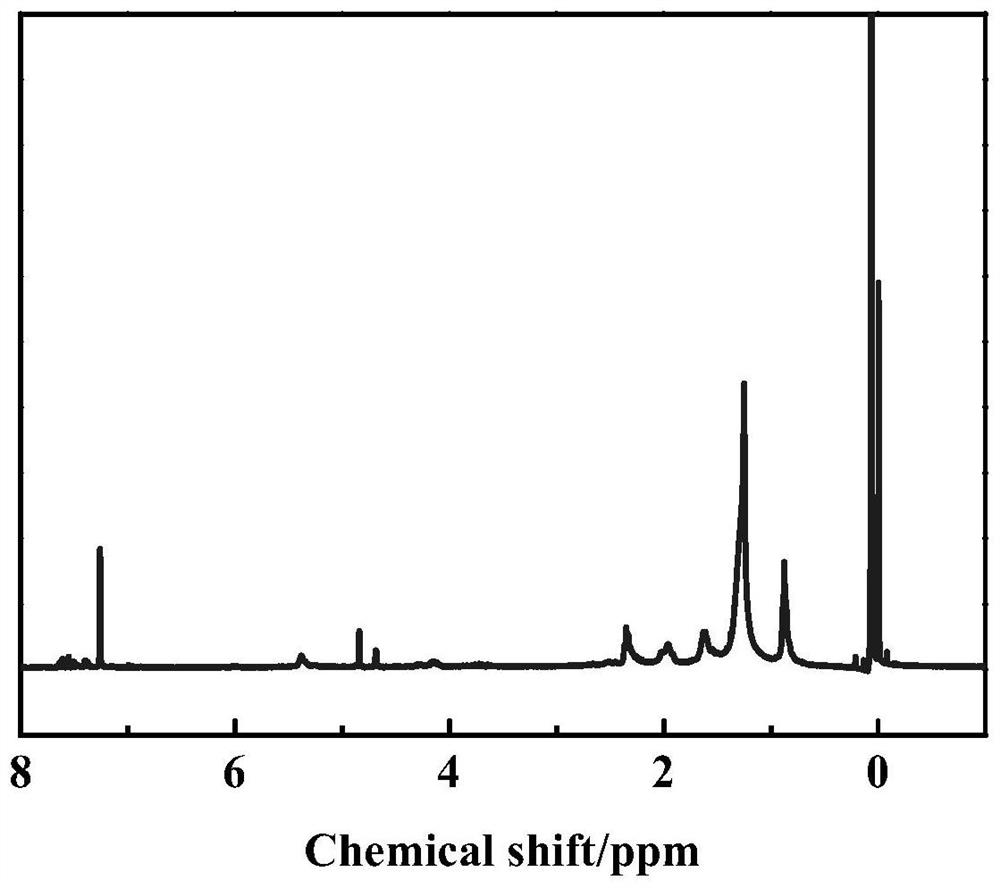

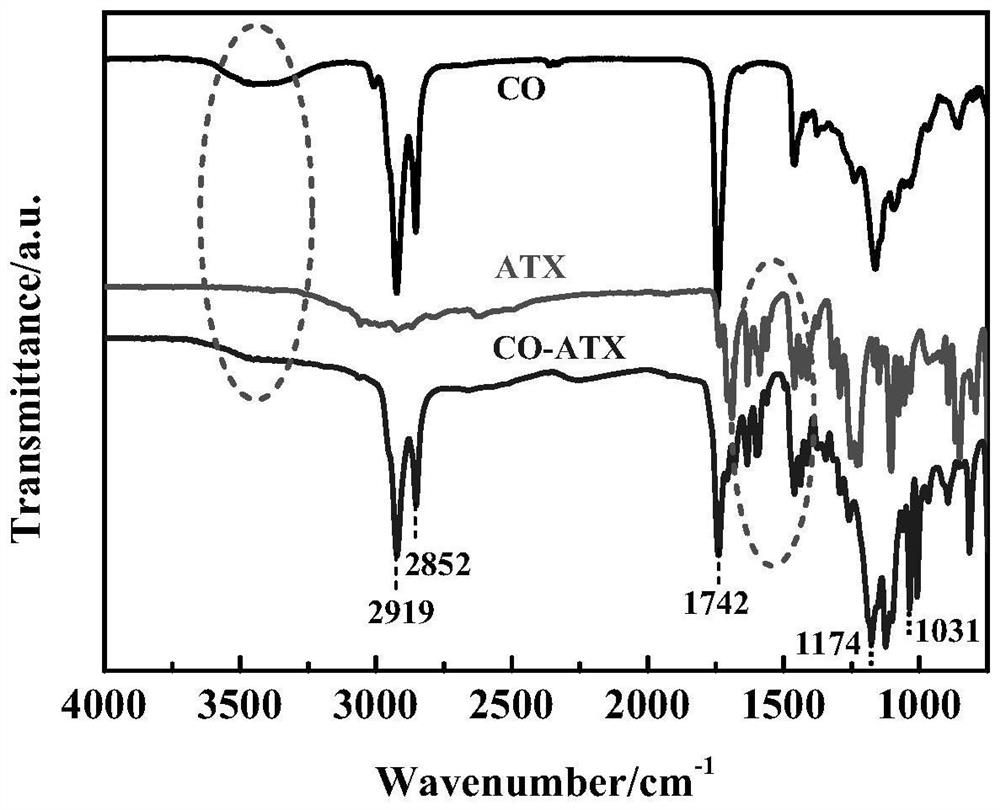

[0073] (1) 7.73g ATX, 9.33g castor oil, 0.86g p-toluenesulfonic acid were added to a clean 50mL three-necked flask with a thermometer, the temperature was increased to 120°C and the pressure was reduced to 130mmHg, and the temperature was lowered to 60°C after the reaction for 6h to obtain 16.52g of yellow viscous liquid is ATX bio-based UV initiator with castor oil as the core.

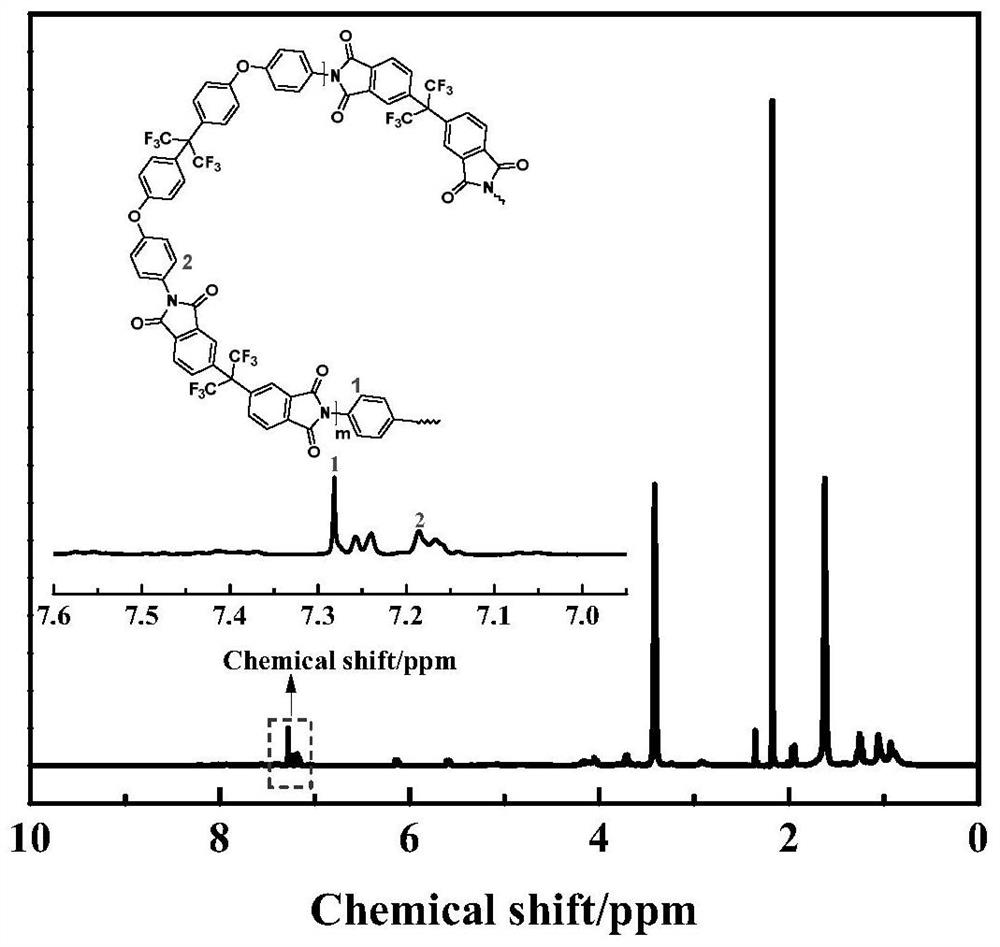

[0074] (2) 12.96g (25mmol) of 2,2-bis[4-(4-aminophenoxybenzene)]hexafluoropropane, 100g of anhydrous tetrahydrofuran and 33.32g (75mmol) of hexafluoropropane were successively added to a 100mL three-necked flask anhydride, reacted at 25°C for 8h. Subsequently, 7.20 g (52.52 mmol) of 4-aminobenzoic acid, 50.0 g of m-dichlorobenzene, and 20 g of anhydrous tetrahydrofuran were added dropwise to the reaction system, the reaction was continued for 16 h at room temperature, and the solvent was removed under reduced pressure at 130 mmHg / 80 °C. , to obtain 98 g of PI white powder.

[0075] Take 61.224g of ga...

Embodiment 2

[0081] According to Table 1, different PIPUAs were prepared, and 40g were taken respectively, and 0.4g of ATX bio-based UV initiators with castor oil as the core obtained in Example 1 were respectively added to them, mixed evenly, and after the bubbles were removed, spin-coating was performed. onto a glass slide, about 0.7mm thick. After UV curing for 60s, the properties of the obtained cured product are shown in Table 3, Figure 5 .

[0082] Table 3 Effects of different PIPUAs on UV-curable materials

[0083]

Embodiment 3

[0085] Take the PIPUA-340g obtained in Example 1, and add the ATX bio-based UV initiator with castor oil as the core obtained in Example 1 to it, mix well, remove the bubbles, spin-coat on a glass slide with a thickness of about 0.7mm. After UV curing for 60s, the properties of the obtained cured product are shown in Table 4.

[0086] Table 4 Effect of different UV initiator dosages on UV curable materials

[0087]

[0088] The above-mentioned ATX bio-based UV initiator dosage is calculated according to the mass percentage of PIPUA-3

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com