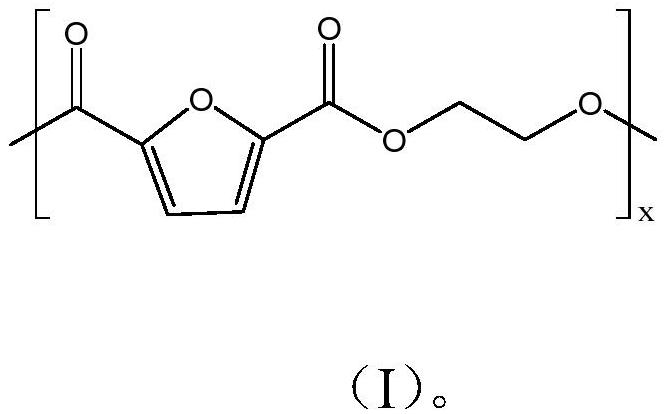

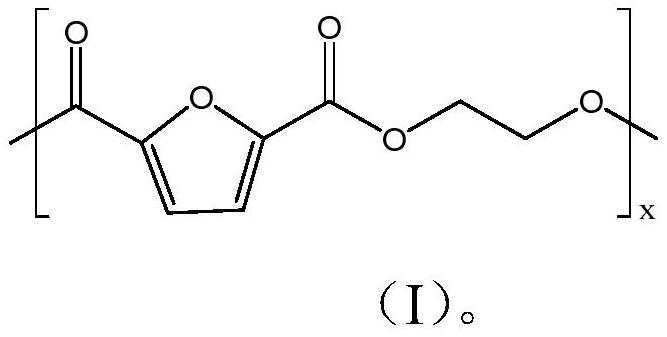

Polymer-based film for dielectric material or energy storage material

A technology of dielectric materials and energy storage materials, which is applied to fixed capacitance parts, thin film/thick film capacitors, laminated capacitors, etc., to achieve high energy storage density, high dielectric constant, and high breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of PEF is as follows:

[0029] Furandicarboxylic acid (0.2mol) was added to a three-necked flask with mechanical stirring and nitrogen protection, followed by adding ethylene glycol (0.32mol) and catalyst tetrabutyl titanate (60 microliters), and reacted at 210 degrees for 2 hours, After that, it was heated to 250 degrees and reacted under vacuum conditions (10 Pa) for 4 hours.

[0030] The PEF was melted at 220°C and then hot pressed into a film with a thickness of 200 microns.

[0031] At 23°C, the dielectric constant was 5.4 and the dielectric loss was 0.019 when tested at 1000 Hz.

Embodiment 2

[0033] The preparation method of PEF is the same as that in Example 1.

[0034] The PEF was melted at 220 °C, and then hot-pressed into a film with a thickness of 30 microns. At 23 °C, the energy storage density at 1000 Hz was 2.4 J / cm. 3 And the charge-discharge efficiency is 96%.

Embodiment 3

[0036] The preparation method of PEF is the same as that in Example 1.

[0037] The PEF was melted at 220°C, and then hot-pressed into a film with a thickness of 30 microns, which had a breakdown strength of 330 MV / m at 23°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy storage density | aaaaa | aaaaa |

| Breakdown strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com