Bio-inspired ultra-sensitive flexible pressure sensor and preparation method thereof

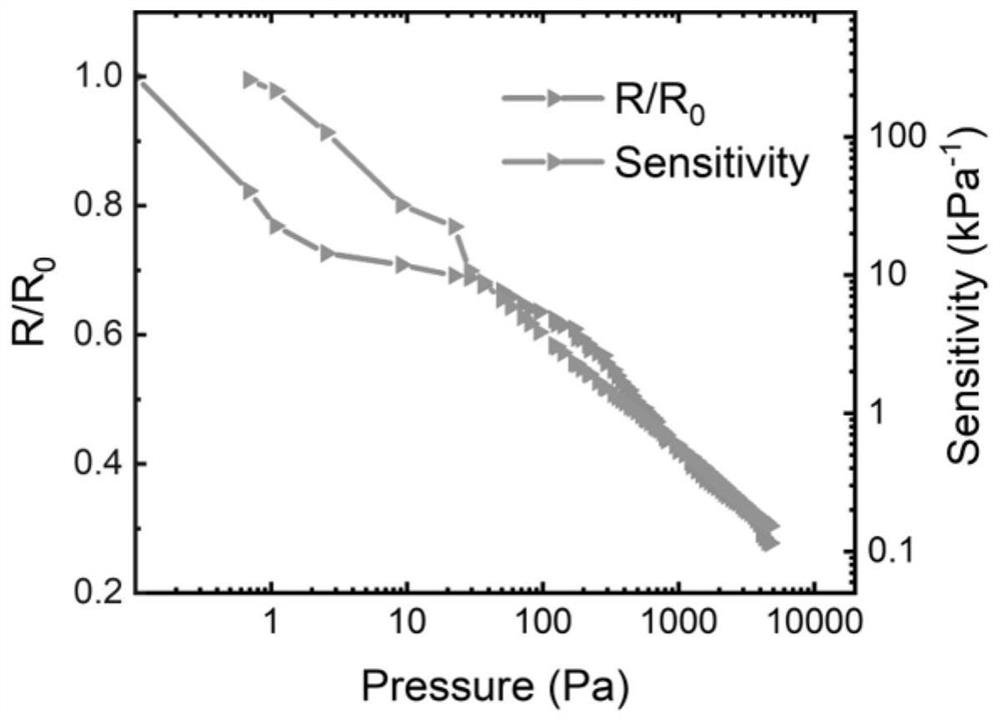

A pressure sensor, bio-inspired technology, applied in the direction of fluid pressure measurement, instrument, and measurement force by changing the ohmic resistance, it can solve the problems of poor temperature stability, long response time, etc., and achieve good adhesion, low detection limit, The effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to specific embodiments and accompanying drawings, but the present invention is not limited to the following embodiments. The methods are conventional methods unless otherwise specified. The raw materials can be obtained from open commercial sources unless otherwise specified.

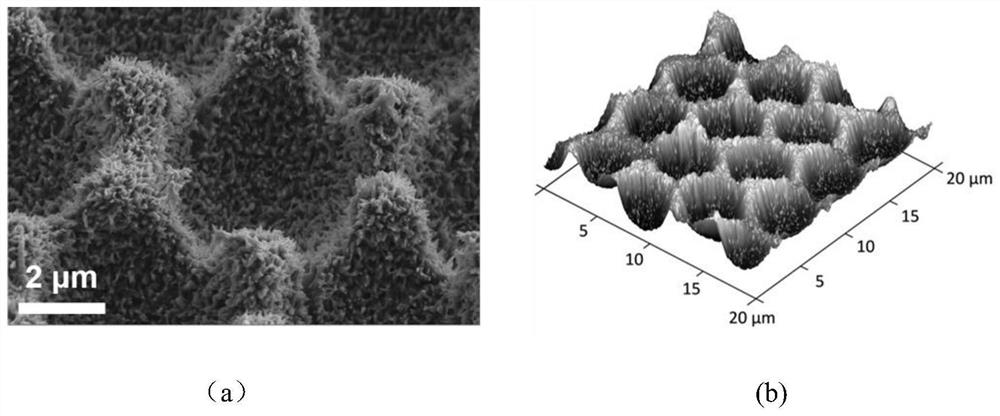

[0037] Dimethicone prepolymer (Dow Corning 184) and curing agent were first mixed in a 2:1 ratio and air bubbles were removed in a vacuum desiccator. The mixture was then spin coated on a glass substrate and cured in an oven at 80°C for 3 hours. Place an appropriate amount of dry powder of 5 μm silica particles on the above polydimethylsiloxane substrate, and use another piece of polydimethylsiloxane cured by the same procedure (prepolymer: curing agent = 10:1) One-way rubbing results in a single-layer silica array template. These templates were then heated at 220°C for 72 hours.

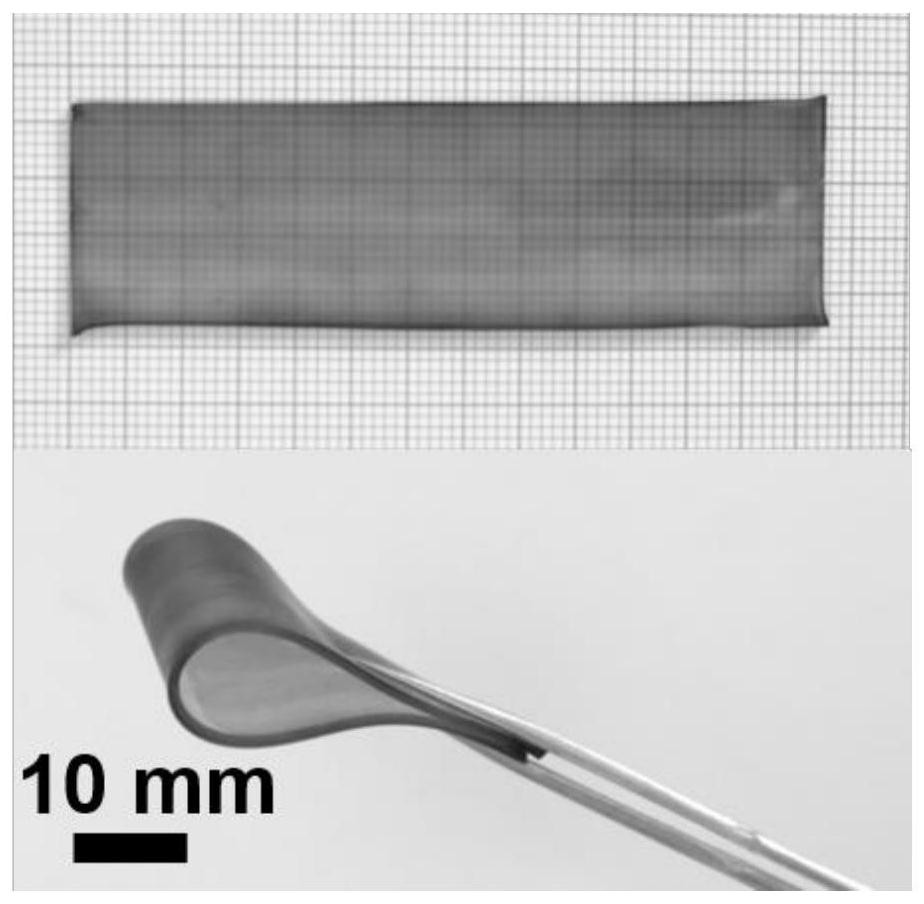

[0038] Afterwards, the polydimethylsiloxan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com