Preparation method of copper-aluminum gradient alloy transition joint for submarine cable welding

A technology of transition joints and gradient alloys, which is applied in the manufacture of contacts and connecting contact materials, etc., can solve the problems of cracking at the junction of materials, difficulty in near-net shape, and complicated processes, and achieve good compactness, improved mechanical properties and The effect of composition uniformity and fast deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

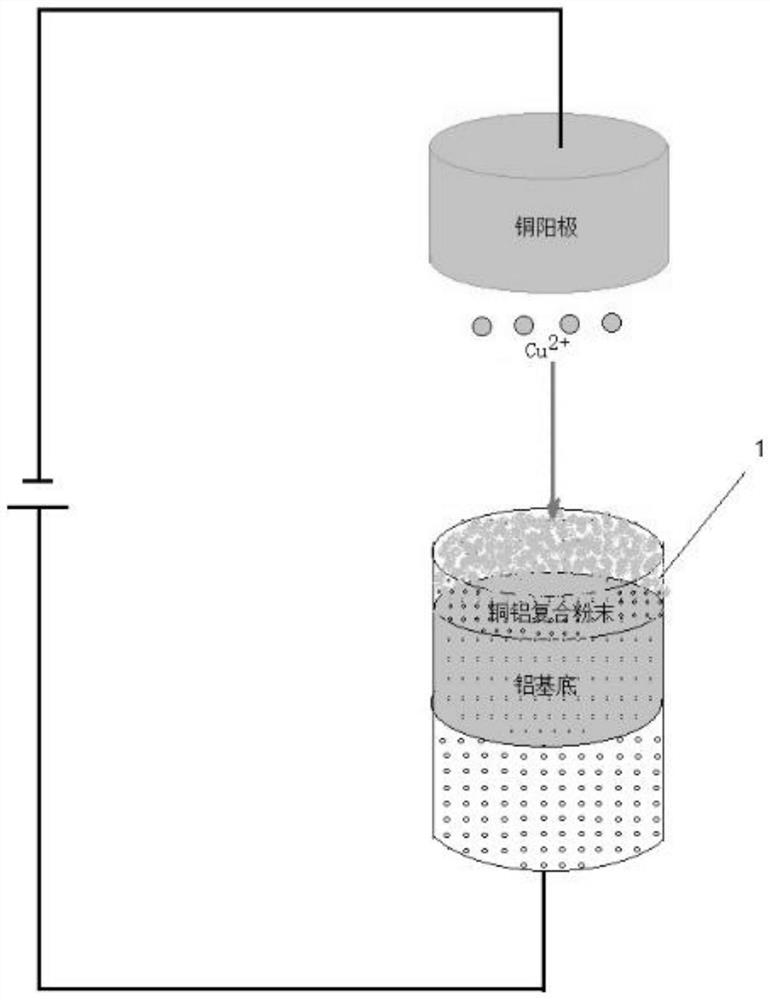

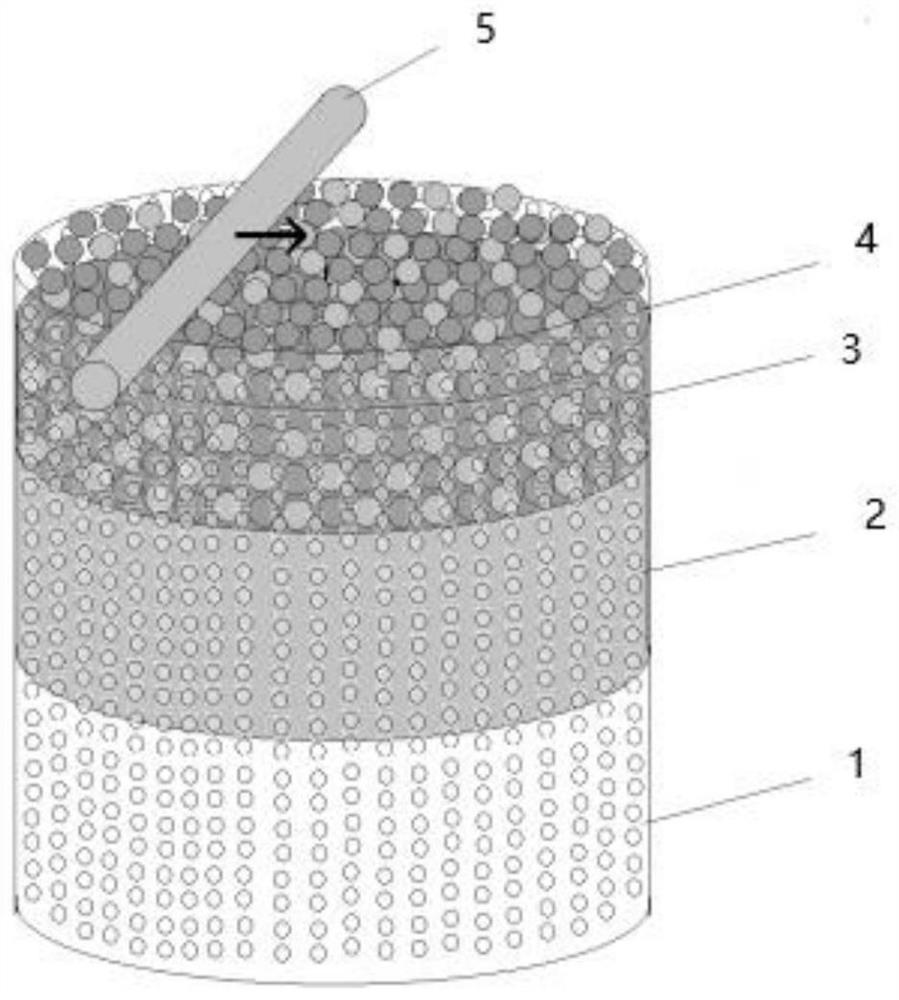

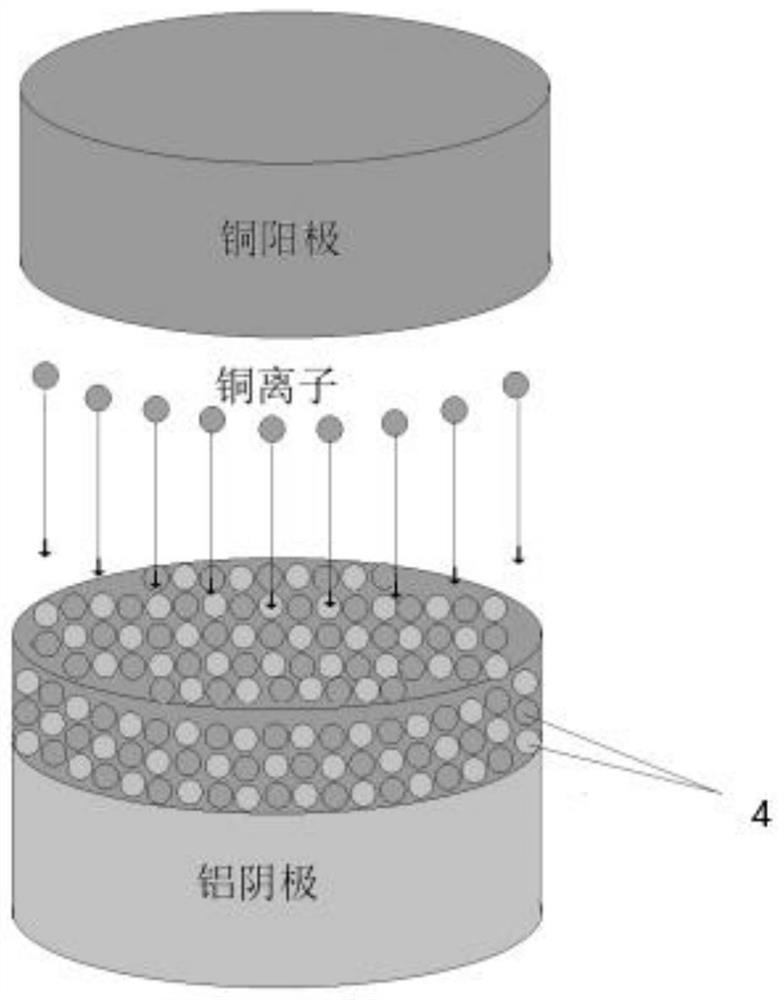

[0031] Example 1: see Figure 1-4The present invention provides a technical solution: a method for preparing a copper-aluminum gradient alloy transition joint for submarine cable welding, the specific steps include: using a mechanical alloying method in advance to prepare several different particle sizes of copper powder and aluminum powder respectively; Add copper powder and aluminum powder into a high-energy ball mill, stainless steel balls are used as grinding media, the ratio of ball to material is 10:1, and grinding is carried out under argon protection to avoid oxidation. The equipment speed should be 330r / min-360r / min, and the ball milling time It should be 24-36 hours. According to the requirements of the number of segments, 6-10 alloy powders with different mixing ratios should be prepared; when mechanical alloying is performed, air is used as a mechanical alloying control agent first, and the ball milling time is 12-16 hours. After that, Add a little alcohol as a mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com