Catalyst for treating wastewater as well as preparation method and application thereof

A technology for treating wastewater and catalysts, applied in catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of insufficient adsorption and activity, and difficulty in achieving the expected effect of organic pollutants, so as to improve reaction kinetics rate, improve biodegradability, reduce COD effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

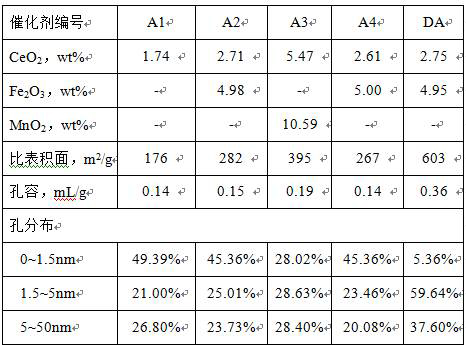

[0041] The silico-alumina was calcined and heat-treated in a high-temperature furnace at 780 °C for 5 h to obtain silica-alumina T1, 93 g of activated carbon was impregnated in Cu-Ce salt solution by supersaturation method, and dried at 100 °C for 5 h to obtain metal-containing activated carbon H1, taking 410 g of T1, 42g chopped polyester fiber filaments were mixed evenly, 14g of silica sol and 21g of glacial acetic acid were added and mixed well, and H1 and water were added and mixed evenly to form a formable mixture, then extruded, dried at 95°C for 5.5h, and heat-treated at 295°C for 6h under nitrogen conditions , then soaked in acetone for 24h, filtered, and then the solid particles dried at 95°C were treated in an aqueous solution containing 444g of sodium hydroxide, recycled for 5h, filtered, and the solid particles were washed with deionized water and dried at 95°C for 6h , calcined at 870 °C for 6 h under nitrogen protection to obtain catalyst A1. The properties of cat...

Embodiment 2

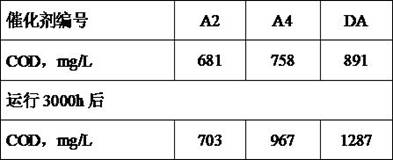

[0043] Heat-treated silico-alumina T2 was obtained by calcining silico-alumina in a high-temperature furnace at 700°C for 8 hours. 712g of activated carbon was impregnated in Fe-Ce salt solution by supersaturation method, and dried at 98°C for 5.5h to obtain metal-containing activated carbon H2. Take 598g of T2 , 125g chopped polyester fiber filaments are mixed evenly, add 46g silica sol, 36g nitric acid and mix well, add H2 and water and mix well to form a formable mixture and extrude, dry at 95 ℃ for 6.5 hours, and soak in nitrogen protection at 300 ℃ for 7 hours. In DMF for 24h, filtered, the solid particles dried at 100°C were treated in an aqueous solution containing 972g of sodium hydroxide, recycled for 6h, filtered, the solid particles were washed with deionized water, dried at 100°C for 6h, nitrogen protection conditions After calcination at 780°C for 6 hours, carbon-containing catalyst A2 was obtained. The properties of catalyst A2 are shown in Table 1.

Embodiment 3

[0045] The silica alumina was calcined in a high temperature furnace at 655 °C for 10 h to obtain heat-treated silica alumina T3, 1173 g of activated carbon was impregnated in a Mn-Ce salt solution by the supersaturation method, and dried at 100 ° C for 6 h to obtain metal-containing activated carbon H3, taking 603 g of T3, 93g of chopped polyethylene fiber filaments are mixed evenly, 67g of aluminum dihydrogen phosphate and 46g of nitric acid are added to mix well, H3 and water are added and mixed evenly to form a formable mixture, then extruded, dried at 95°C for 6.5h, and heat-treated at 300°C under nitrogen protection for 6h After immersion in chloroform for 20 hours, filtered, the solid particles dried at 100 °C were treated with an aqueous solution containing 818 g of sodium hydroxide, recycled for 5 hours, filtered, and the solid particles were washed with deionized water and dried at 100 °C for 5 hours , calcined at 800 °C for 4 h under nitrogen protection to obtain car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com