Surface lubricating treatment agent applied to galvanized steel sheet and treatment method of surface lubricating treatment agent

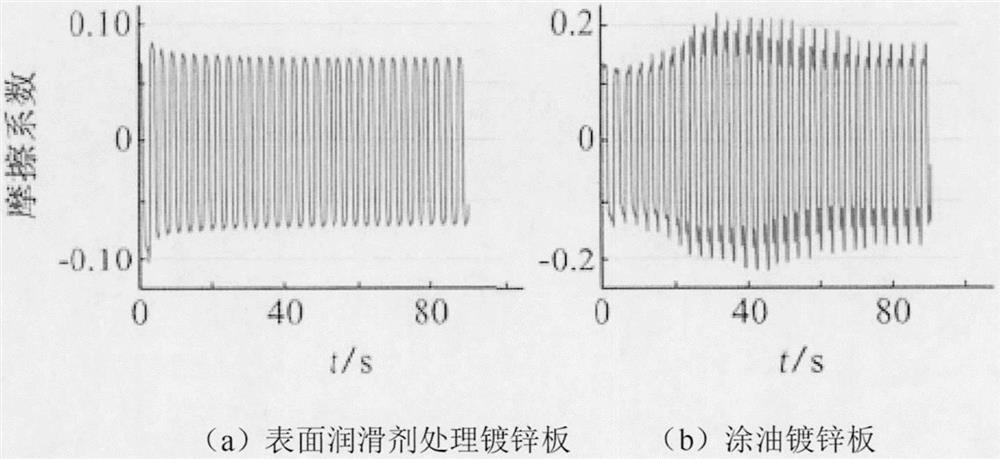

A technology of galvanized steel sheet and treatment agent, which is applied in the coating process of metal materials, etc., and can solve problems such as coating powder falling off, affecting the surface quality of stamping parts, and zinc sticking to molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better explain the present invention, the main content of the present invention is further clarified in conjunction with the following specific examples, but the content of the present invention is not limited to the following examples.

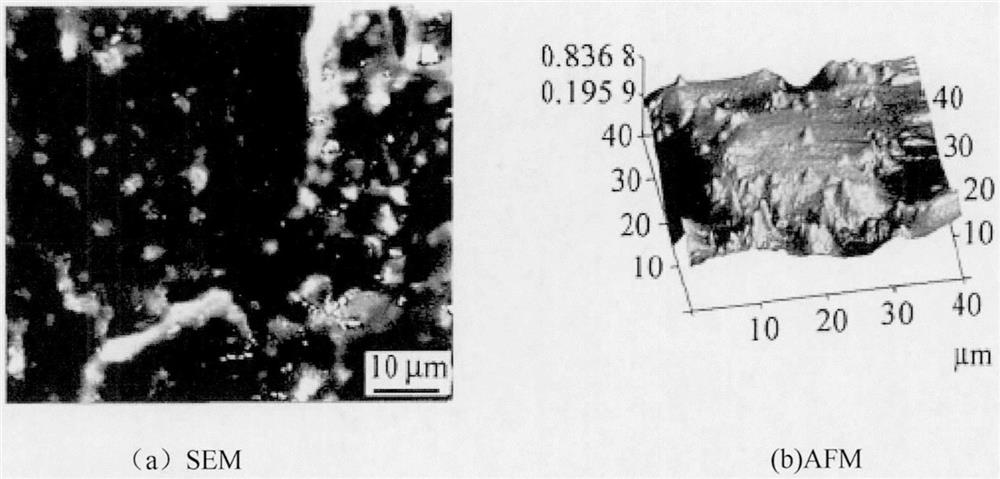

[0025] The substrate in the embodiment is a galvanized steel sheet with no oil stains and other impurities on the surface.

[0026] The surface treatment agent was formulated with the ingredients in Table 1 below.

[0027] The galvanized steel strip is dip-coated in a solution tank equipped with the above-mentioned surface treatment agent, the time is controlled within the range of 30-80s (seconds), and the drying is carried out at a temperature of 70-140°C.

[0028] Table 1 Composition ratio of surface lubricant treatment agent

[0029] Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Mn 2+

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com