Preparation method of tungsten disulfide nanosheet modified cadmium sulfide photocatalyst

A technology of photocatalyst and tungsten disulfide, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve problems such as low solar conversion efficiency and photocorrosion, and achieve improved photostability, good light Stability, effect of inhibiting photocorrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0041] Embodiment 1: The preparation method of a tungsten disulfide nanosheet modified cadmium sulfide photocatalyst in this embodiment is carried out according to the following steps:

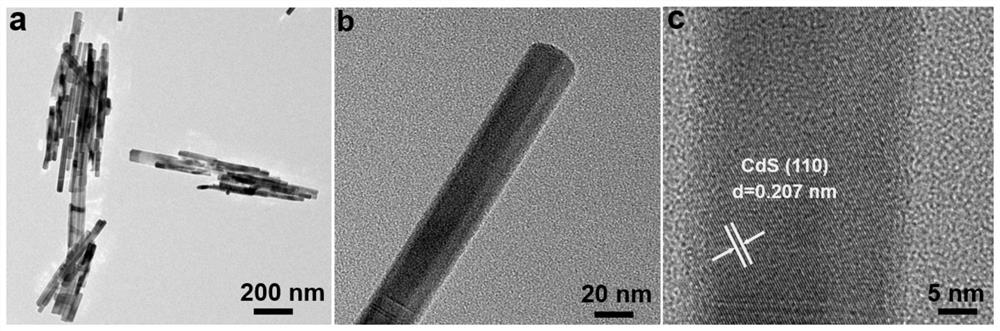

[0042] Step 1. Add cadmium nitrate tetrahydrate and thiourea into ethylenediamine, stir magnetically, and then put it into a polytetrafluoroethylene reactor for solvothermal reaction, then naturally cool to room temperature, wash with deionized water, and dry , to obtain CdS nanorods;

[0043] Step 2, fully grinding dicyandiamide, ammonium metatungstate and the CdS nanorods obtained in step 1 to obtain a uniformly mixed pale yellow powder;

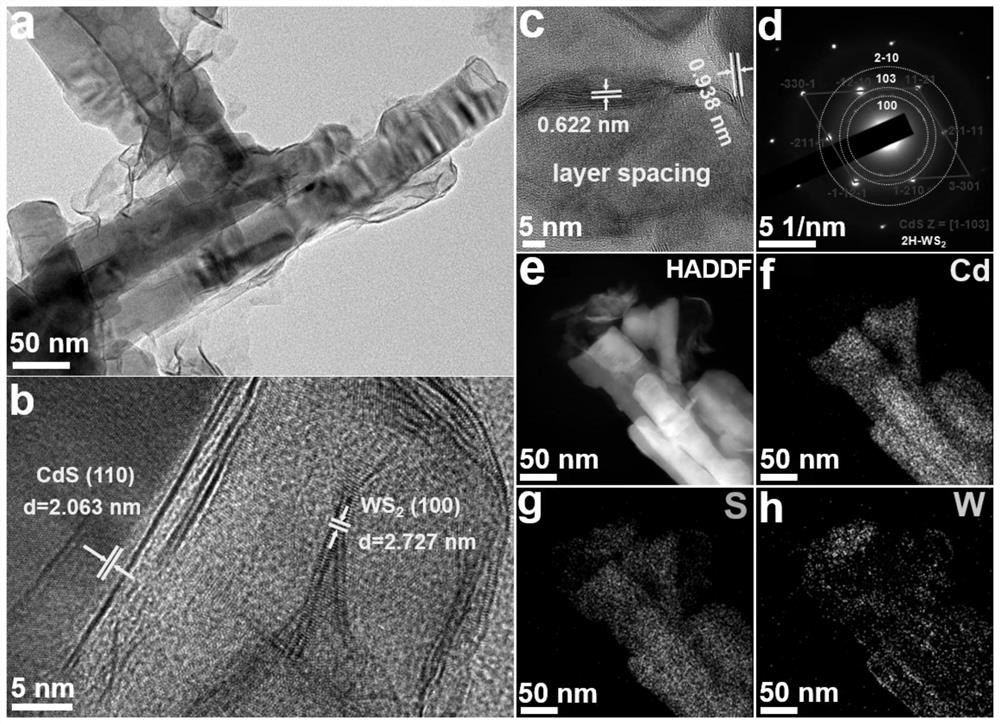

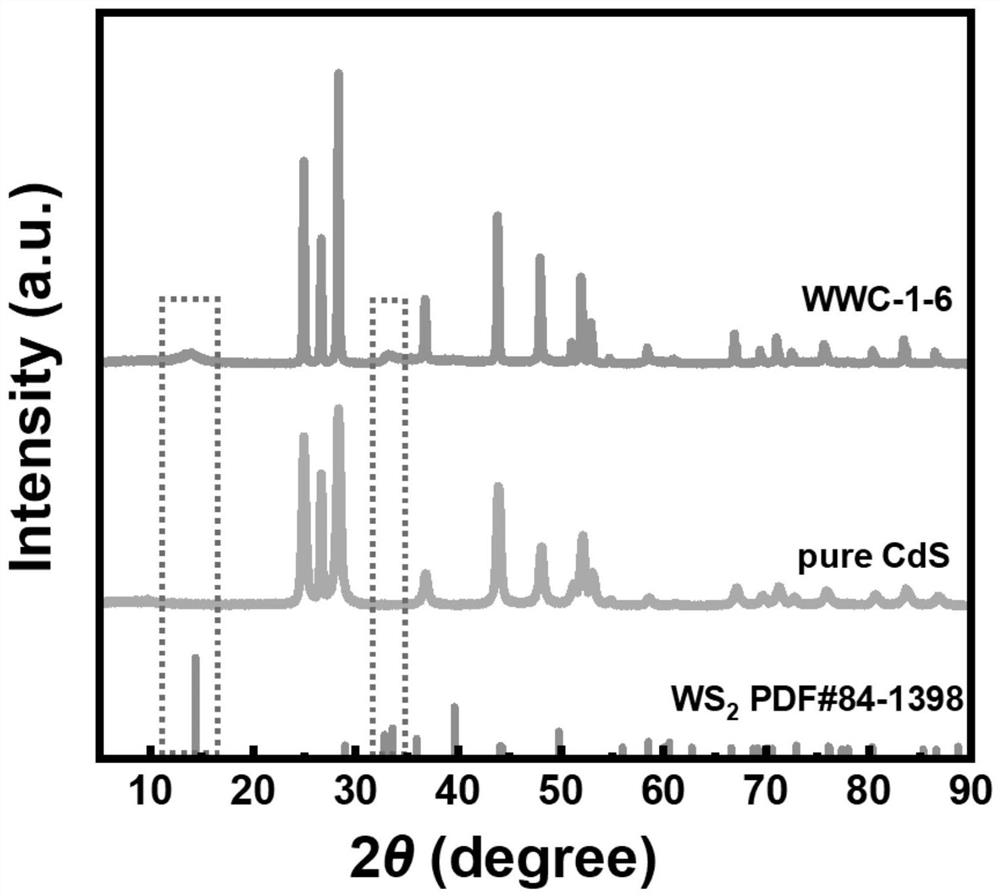

[0044] Step 3. The light yellow powder obtained in step 2 is heated from room temperature to 400-500 ℃ in a nitrogen atmosphere, kept warm, then heated to 800-900 ℃, kept warm, and then naturally cooled to room temperature to obtain 1T-WS 2 / 2H-WS 2 / CdS nanoheterojunction photocatalyst, namely tungsten disulfide nanosheet modified cadmium sulfide photoc...

specific Embodiment approach 2

[0045] Embodiment 2: The difference between this embodiment and Embodiment 1 is: in step 1, the addition amount of cadmium nitrate tetrahydrate is 0.5-1.5g, the addition amount of thiourea is 0.5-2g, and the addition amount of ethylenediamine is 25mL. Others are the same as the first embodiment.

specific Embodiment approach 3

[0046] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that: in step 1, the magnetic stirring time is 30-40 min, and the rotational speed is 600-1000 rpm. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com