Nickel-silicon catalyst suitable for methane dry reforming and preparation method thereof

A technology for methane dry reforming and nickel-based catalysts, which is applied in catalyst activation/preparation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of high cost, difficult application, high cost catalytic activity, etc. The effect of good stability, high activity and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

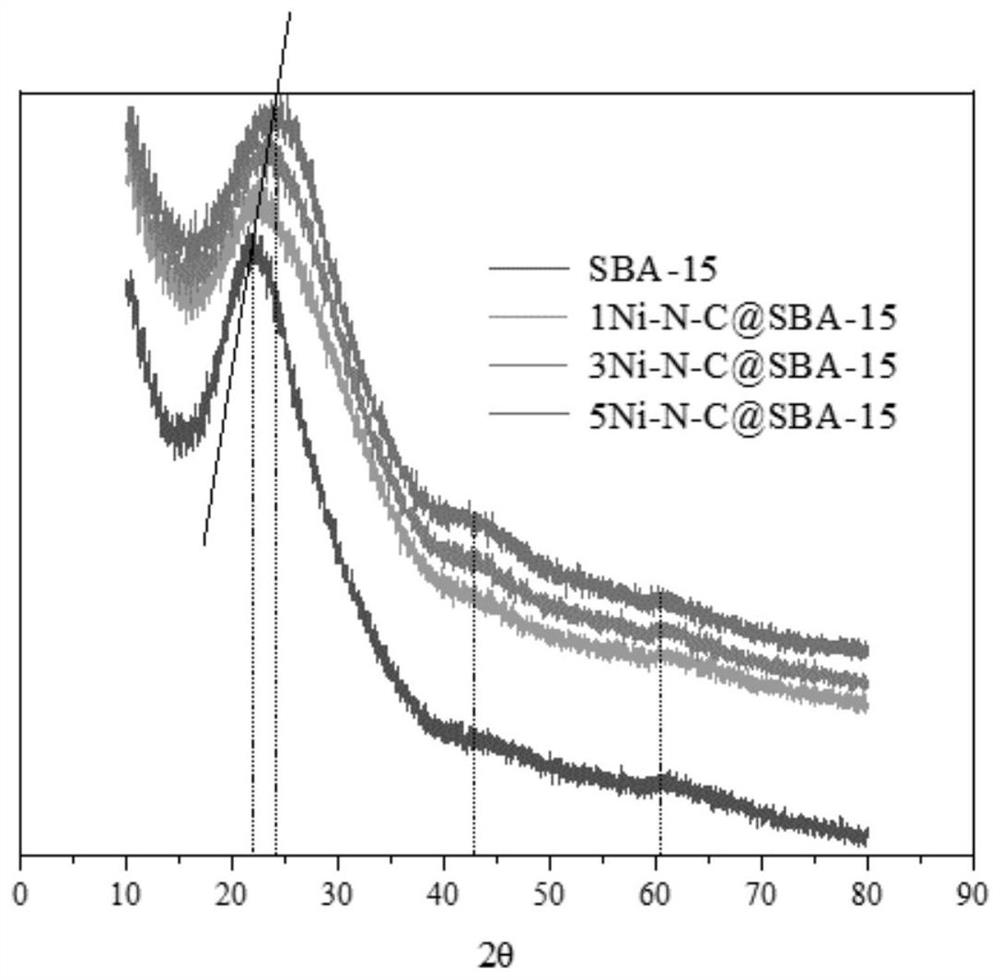

Embodiment 1

[0040] The invention provides a preparation method of a nickel-silicon catalyst suitable for methane dry reforming, comprising the following steps:

[0041] (1) Silica supported nickel salt: In a 25ml glass vial, add 20ml of deionized water, SBA-15 (400mg), nickel nitrate hexahydrate (20.02mg, 0.07mmol), α-D glucose (292.9mg, 1.51 mmol), the obtained mixture was ultrasonically dispersed for 30 min, stirred at room temperature overnight, and dried at 100° C. to obtain a silica-supported nickel salt.

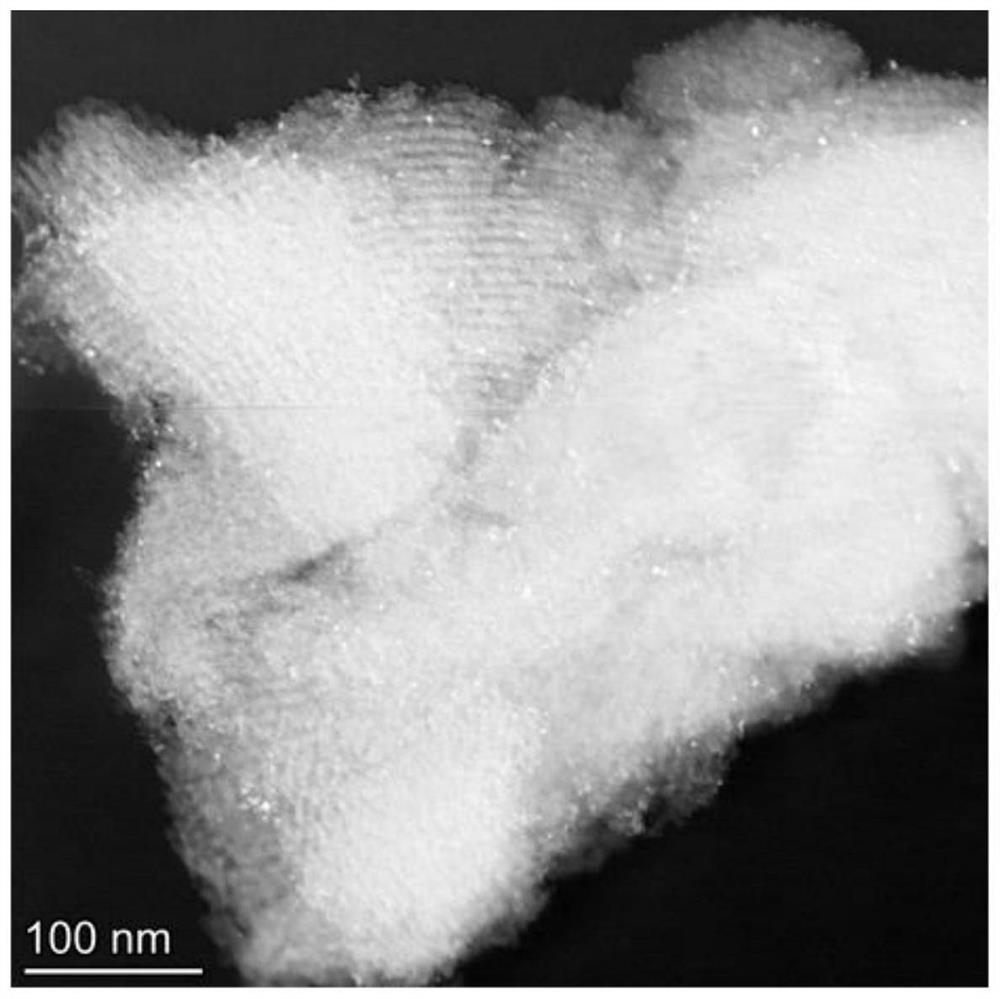

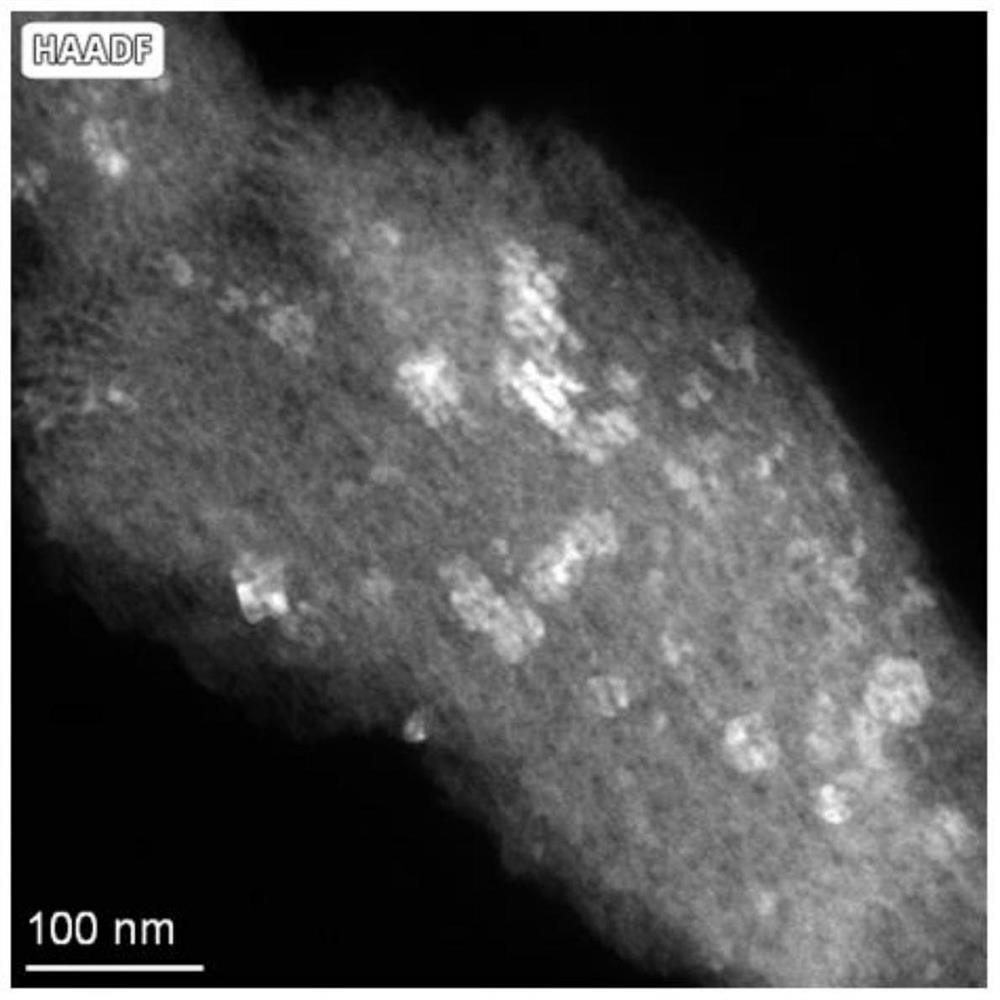

[0042] (2) Ni-N-C-coated silica: fully grind the silica-supported nickel salt and 2 g melamine obtained after drying, and the ground powder is heated at 800°C under nitrogen atmosphere (the heating rate is 5°C / min) Carbonized for 2h to obtain Ni-N-C coated silica material.

[0043] (3) Silica-supported nickel-based catalyst: The Ni-N-C-coated silica material was calcined at 500 °C for 1 h in an air atmosphere to remove the carbon host to obtain the final silica-supported nickel-b...

Embodiment 2

[0045](1) Silica-supported nickel salt: in a 25ml glass vial, add 20ml of deionized water, SBA-15 (400mg), nickel nitrate hexahydrate (61.3mg, 0.21mmol), α-D glucose (835.6mg, 4.64 mg) mmol), the obtained mixture was ultrasonically dispersed for 30 min, stirred at room temperature overnight, and dried at 100° C. to obtain a silica-supported nickel salt.

[0046] (2) Ni-N-C-coated silica: fully grind the silica-supported nickel salt and 2 g melamine obtained after drying, and the ground powder is heated at 800°C under nitrogen atmosphere (the heating rate is 5°C / min) Carbonized for 2h to obtain Ni-N-C coated silica material.

[0047] (3) Silica-supported nickel-based catalyst: The Ni-N-C-coated silica material was calcined at 500 °C for 1 h in an air atmosphere to remove the carbon host to obtain the final silica-supported nickel-based catalyst 3Ni@SBA-15 .

Embodiment 3

[0049] (1) Silica-supported nickel salt: In a 25ml glass vial, add 20ml of deionized water, SBA-15 (400mg), nickel nitrate hexahydrate (104.3mg, 0.36mmol), α-D glucose (1422.0mg, 7.89 mmol), the obtained mixture was ultrasonically dispersed for 30 min, stirred at room temperature overnight, and dried at 100° C. to obtain a silica-supported nickel salt.

[0050] (2) Ni-N-C-coated silica: fully grind the silica-supported nickel salt and 2 g melamine obtained after drying, and the ground powder is heated at 800°C under nitrogen atmosphere (the heating rate is 5°C / min) Carbonized for 2h to obtain Ni-N-C coated silica material.

[0051] (3) Silica-supported nickel-based catalyst: The Ni-N-C-coated silica material was calcined at 500 °C for 1 h in an air atmosphere to remove the carbon host to obtain the final silica-supported nickel-based catalyst 5Ni@SBA-15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com