Silver nanowire with core-shell structure and preparation method and application thereof

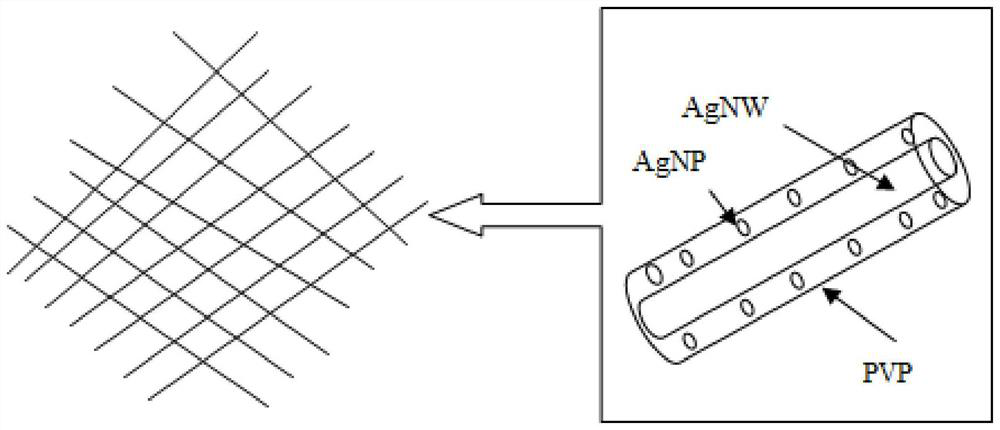

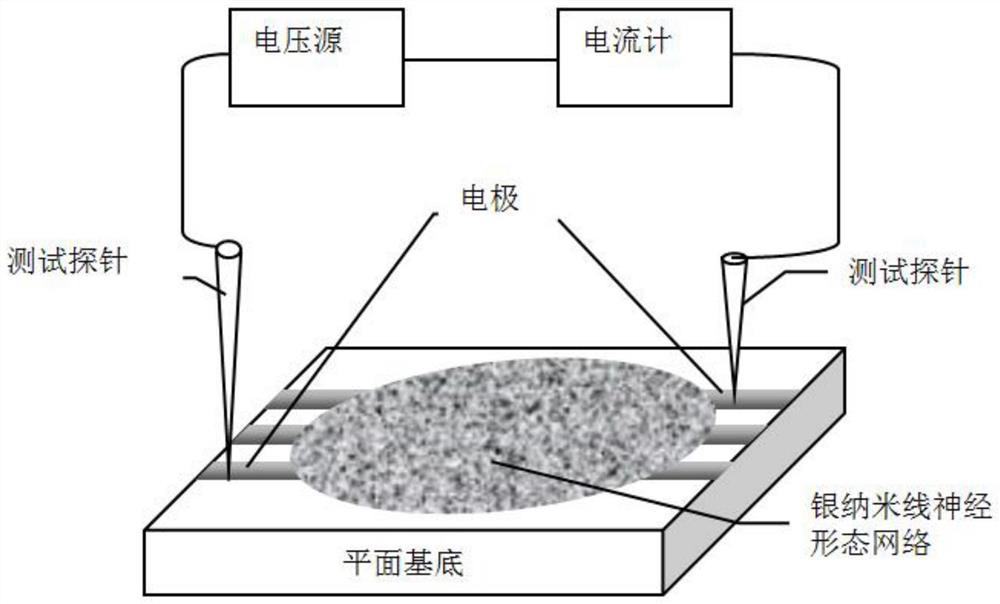

A technology of silver nanowires and core-shell structure, which is applied in the fields of nanotechnology, nanotechnology and nanotechnology for material and surface science, and achieves the effects of low preparation cost, improved dynamic decay rate, and increased reservoir scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In some embodiments, the method for preparing silver nanowires with a core-shell structure includes the following steps:

[0046] Weigh silver acetate and / or silver nitrate, add deionized water to make solution A; weigh glucose, add deionized water to make solution B; weigh PVP, add deionized water to make solution C;

[0047] Weigh NaCl, add deionized water to make solution D;

[0048] Mix solution A and solution B, stir, then add solution C to continue stirring, then add solution D and ultrasonically disperse to obtain a mixed solution; in the mixed solution, Ag + The concentration of PVP is 10~30wt%, the concentration of glucose is 10~30wt%, the concentration of PVP is 10~30wt%, the - The concentration is 10~30wt%.

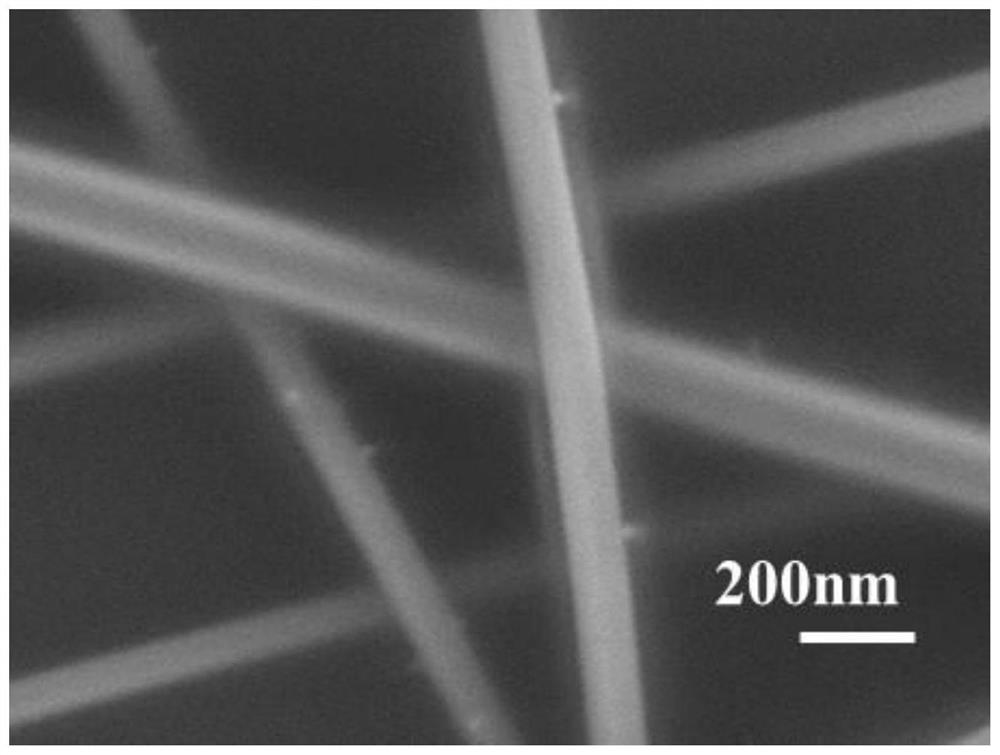

[0049] The obtained mixed solution was poured into a closed hydrothermal reactor, and reacted at 130 to 180 ° C for 12 to 22 hours to obtain silver nanowires with a core-shell structure. figure 2 It is an SEM image of a silver nanowire with a core-sh...

Embodiment 1

[0054] Preparation of silver nanowires:

[0055] First, weigh 0.025 g of silver acetate powder and 0.025 g of silver nitrate powder into a beaker, add 15 mL of deionized water to make solution A; secondly weigh 0.12 g of glucose into a beaker, add 5 mL of deionized water to make up Solution B; then weigh 1 g of PVP into a beaker, add 5 mL of deionized water to make solution C; finally weigh 0.035 g of NaCl into a beaker, add 15 mL of deionized water to make solution D.

[0056] Next, solution A was mixed with solution B, stirred for 10 minutes, then added with solution C and continued to stir for 20 min, then added with solution D and dispersed by ultrasonic for 5 min.

[0057] Finally, the obtained mixed solution was poured into a closed hydrothermal reactor, and reacted at 130°C for 22 hours to obtain a silver nanowire product. The silver nanowires prepared in this example have an average length of about 38 μm, an average diameter of about 36 nm, an aspect ratio of about 10...

Embodiment 2

[0061] Preparation of silver nanowires:

[0062] First, weigh 0.02 g of silver acetate and 0.08 g of silver nitrate powder into a beaker, add 25 mL of deionized water to make solution A; secondly weigh 0.36 g of glucose into a beaker, add 5 mL of deionized water to make solution B ; Then weigh 0.05 g of PVP into a beaker, add 5 mL of deionized water to make solution C; finally weigh 0.03 g of KCl into a beaker, add 15 mL of deionized water to make solution D.

[0063] Next, solution A was mixed with solution B, stirred for 15 minutes, then added with solution C and continued to stir for 20 min, then added with solution D and dispersed by ultrasonic for 5 min. Finally, the obtained mixed solution was poured into a closed hydrothermal reactor, and the reaction was carried out at 150° C. for 22 hours to obtain a silver nanowire product. The silver nanowires prepared in this example have an average length of about 25 μm, an average diameter of about 56 nm, an aspect ratio of abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com