Method for eliminating wrinkles of two-dimensional material and application of method

A two-dimensional material and wrinkle technology, applied in the fields of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of low success rate, low efficiency, limited application of two-dimensional materials, etc., to achieve simple operation, high efficiency, elimination of high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

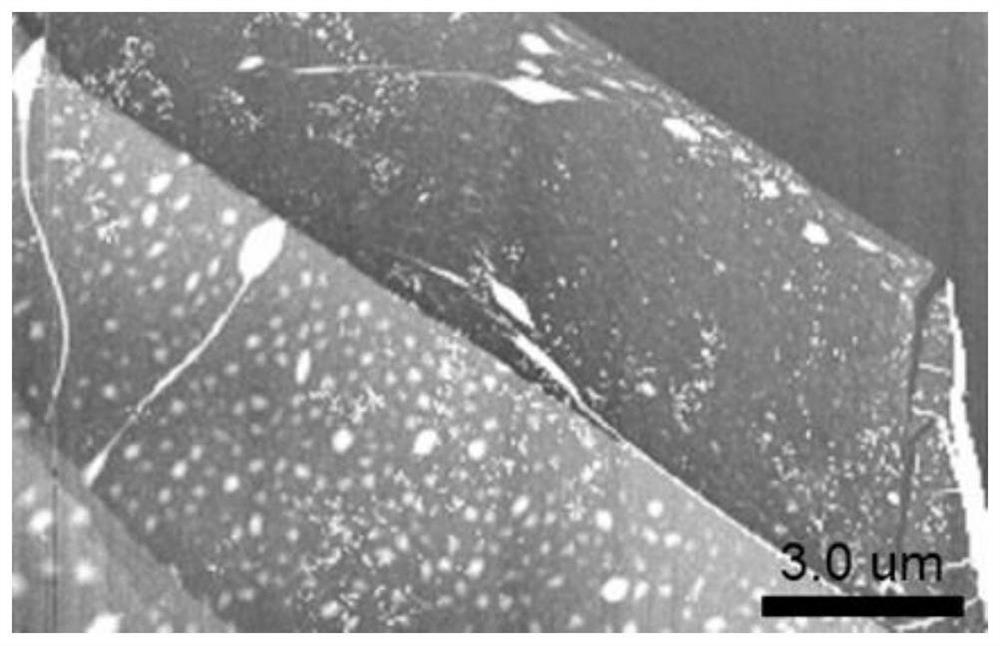

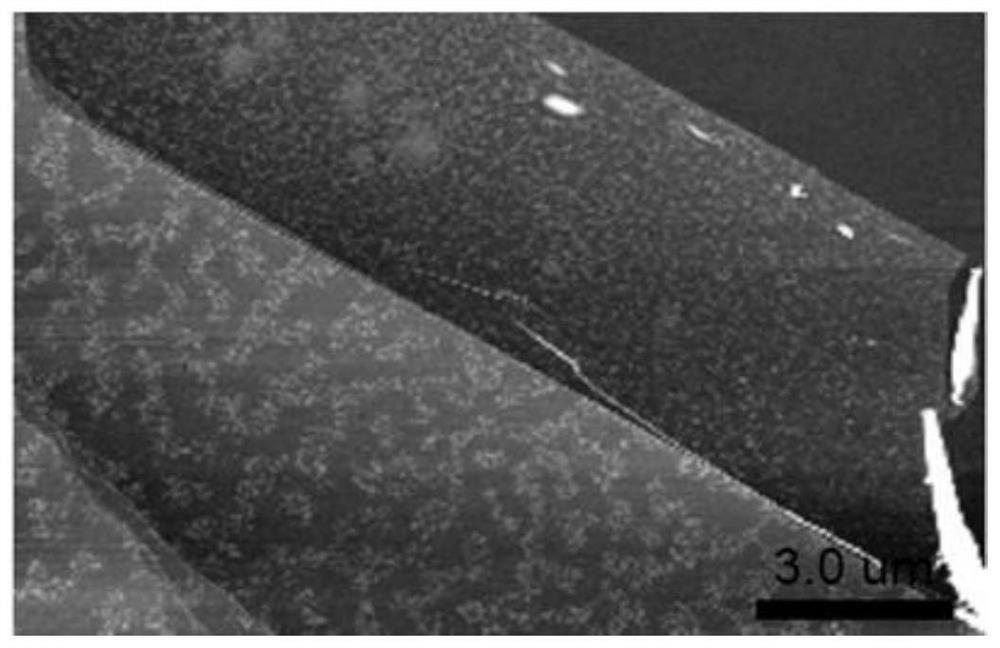

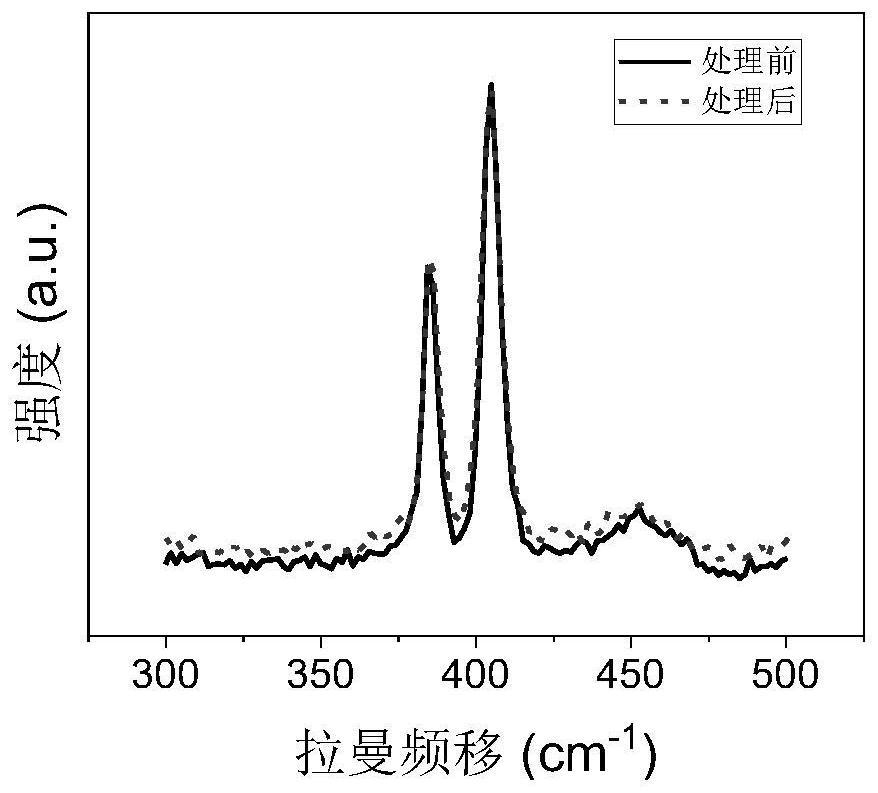

[0055] A method for eliminating double-layer molybdenum disulfide folds, specifically comprising the following steps:

[0056] (1) Mechanically exfoliate a bilayer (about 1.3 nm in thickness) of molybdenum disulfide on dimethylsiloxane, and then transfer the bilayer molybdenum disulfide to a silicon substrate using a three-dimensional stage under an optical microscope , to obtain a double-layer molybdenum disulfide sample attached to a silicon substrate;

[0057] (2) Immerse the double-layer molybdenum disulfide sample attached to the silicon substrate obtained in step (1) in chromatographic grade absolute ethanol for 1 h with tweezers (cover the mouth of the cup with tin foil to prevent the evaporation of absolute ethanol), then Using tweezers, the double-layer molybdenum disulfide sample attached to the silicon substrate was taken out and dried by nitrogen blowing, and finally placed in a quartz tube of a vacuum tube furnace for annealing under the protection of a 1:9 mixtur...

Embodiment 2

[0061] A method for three-layer graphene folds, specifically comprising the steps:

[0062] (1) The three-layer graphene (thickness is about 1.2 nm) was mechanically exfoliated on dimethylsiloxane, and then the three-layer graphene was transferred to the silicon substrate using a three-dimensional stage under an optical microscope to obtain a bonding Three-layer graphene samples on silicon substrates;

[0063] (2) Immerse the three-layer graphene sample attached to the silicon substrate obtained in step (1) in chromatographic grade absolute ethanol for 1 h with tweezers (cover the mouth of the cup with tin foil to prevent the evaporation of absolute ethanol), and then use The three-layer graphene sample attached to the silicon nitride substrate was taken out with tweezers and dried by nitrogen blowing. Finally, it was placed in a quartz tube of a vacuum tube furnace for annealing under the protection of a 1:9 mixture of hydrogen and argon. After 2 hours of treatment, the temp...

Embodiment 3

[0067] A method for eliminating wrinkles of single-layer molybdenum disulfide, specifically comprising the following steps:

[0068] (1) Mechanically exfoliate molybdenum disulfide containing a monolayer (thickness of about 0.65 nm) on dimethylsiloxane, and then transfer the monolayer molybdenum disulfide to a molybdenum disulfide with holes under an optical microscope using a three-dimensional stage. On the silicon nitride substrate obtained, a suspended monolayer molybdenum disulfide sample attached to the silicon nitride substrate was obtained;

[0069] (2) Immerse the suspended monolayer of molybdenum disulfide attached to the silicon nitride substrate obtained in step (1) in chromatographic grade absolute ethanol for 1 h with tweezers (cover the mouth of the cup with tin foil to prevent the evaporation of the absolute ethanol) , and then use tweezers to take out the suspended monolayer molybdenum disulfide on the silicon nitride substrate and dry it with nitrogen blowing,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com