Corrosion-resistant and scouring-resistant surface protection method for oil well packer

A packer and corrosion-resistant technology, which is applied to the surface coating liquid device, anti-corrosion coating, coating, etc., can solve the problems of unsatisfactory protection effect, reduce oil well maintenance and production costs, and improve penetration and invasion Difficulty, the effect of reducing the risk of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

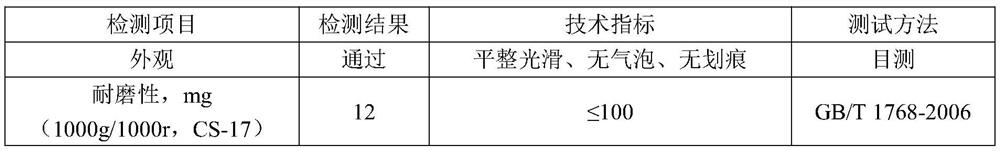

Embodiment 1

[0021] A corrosion-resistant and erosion-resistant surface protection method for an oil well packer, comprising the following process steps:

[0022] The first step is to clean the metal components of the oil well packer before painting. The specific processing steps are as follows: first, clean the metal components with industrial pure water, ultrasonically clean and remove oil with metal degreasing solution at a temperature of 55 °C, and use industrial pure water. Cleaning, rust removal liquid ultrasonic surface rust removal at a temperature of 50 ℃, industrial pure water cleaning, pure water cleaning, UV ultrapure water cleaning, high temperature drying room 130 ℃ drying water.

[0023] In the second step, the bottom protective layer (phosphate ceramic membrane protective layer) is prepared on the metal components of the oil well packer. The specific process operations are as follows: the cleaned metal components of the oil well packer are immersed in the phosphate treatment...

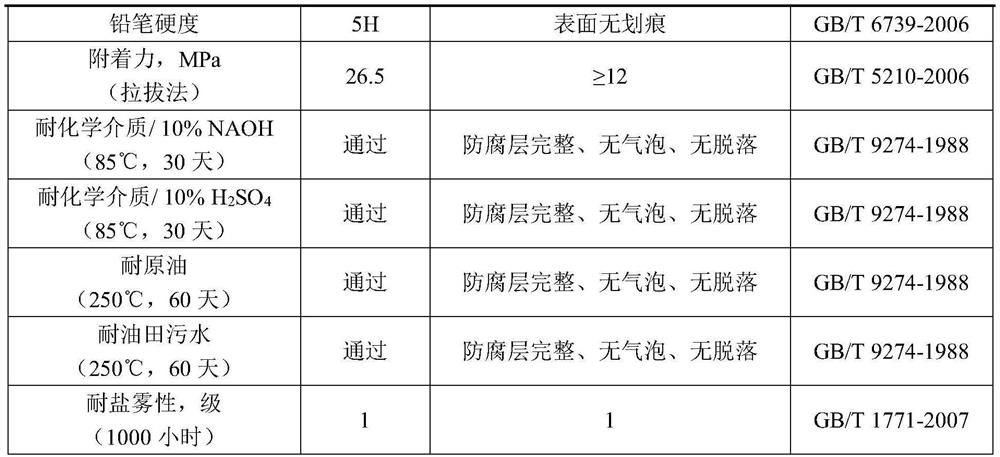

Embodiment 2

[0034] A corrosion-resistant and erosion-resistant surface protection method for an oil well packer, comprising the following process steps:

[0035] The first step is to clean the metal components of the oil well packer before painting. The specific processing steps are as follows: first, clean the metal components with industrial pure water, ultrasonically clean and remove oil with metal degreasing solution at a temperature of 55 °C, and use industrial pure water. Cleaning, rust removal solution ultrasonic surface rust removal at a temperature of 50 ℃, industrial pure water cleaning, pure water cleaning, UV ultrapure water cleaning, high temperature drying room 120 ℃ drying water.

[0036] In the second step, the bottom protective layer (phosphate ceramic membrane protective layer) is prepared on the metal components of the oil well packer. The specific process operations are as follows: the cleaned metal components of the oil well packer are immersed in the phosphate treatme...

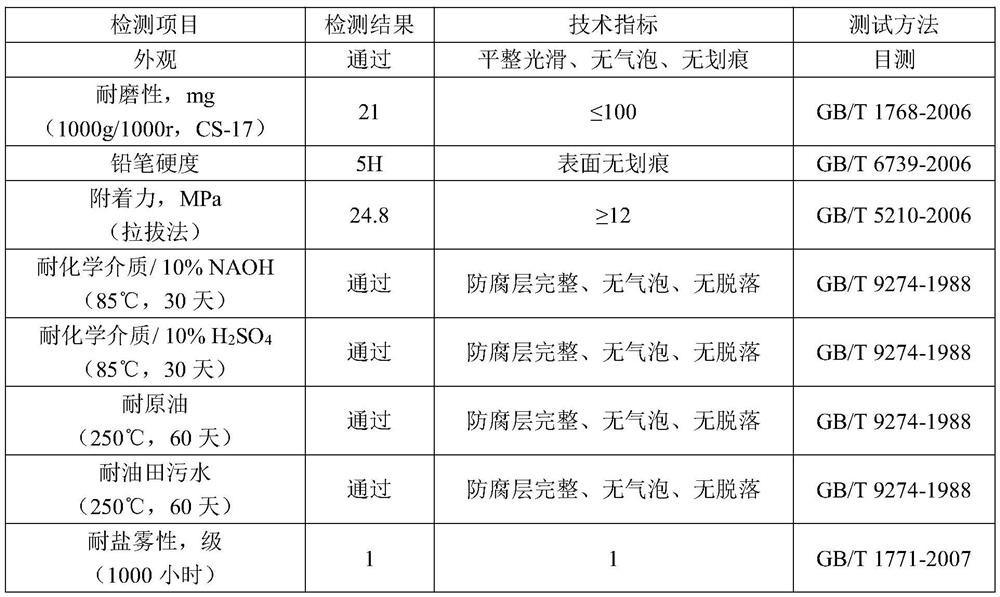

Embodiment 3

[0046] A corrosion-resistant and erosion-resistant surface protection method for an oil well packer, comprising the following process steps:

[0047] The first step is to clean the metal components of the oil well packer before painting. The specific processing steps are as follows: first, clean the metal components with industrial pure water, ultrasonically clean and remove oil with metal degreasing solution at a temperature of 55 °C, and use industrial pure water. Cleaning, rust removal liquid ultrasonic surface rust removal at a temperature of 50 ℃, industrial pure water cleaning, pure water cleaning, UV ultrapure water cleaning, high temperature drying room 130 ℃ drying water.

[0048] In the second step, the bottom protective layer (phosphate ceramic membrane protective layer) is prepared on the metal components of the oil well packer. The specific process operations are as follows: the cleaned metal components of the oil well packer are immersed in the phosphate treatment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com