Preparation method of waterborne polyurethane adhesive

A water-based polyurethane and adhesive technology, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of low minimum activation temperature, low production efficiency, high peel strength, etc., and achieve good bonding effect , high production efficiency and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

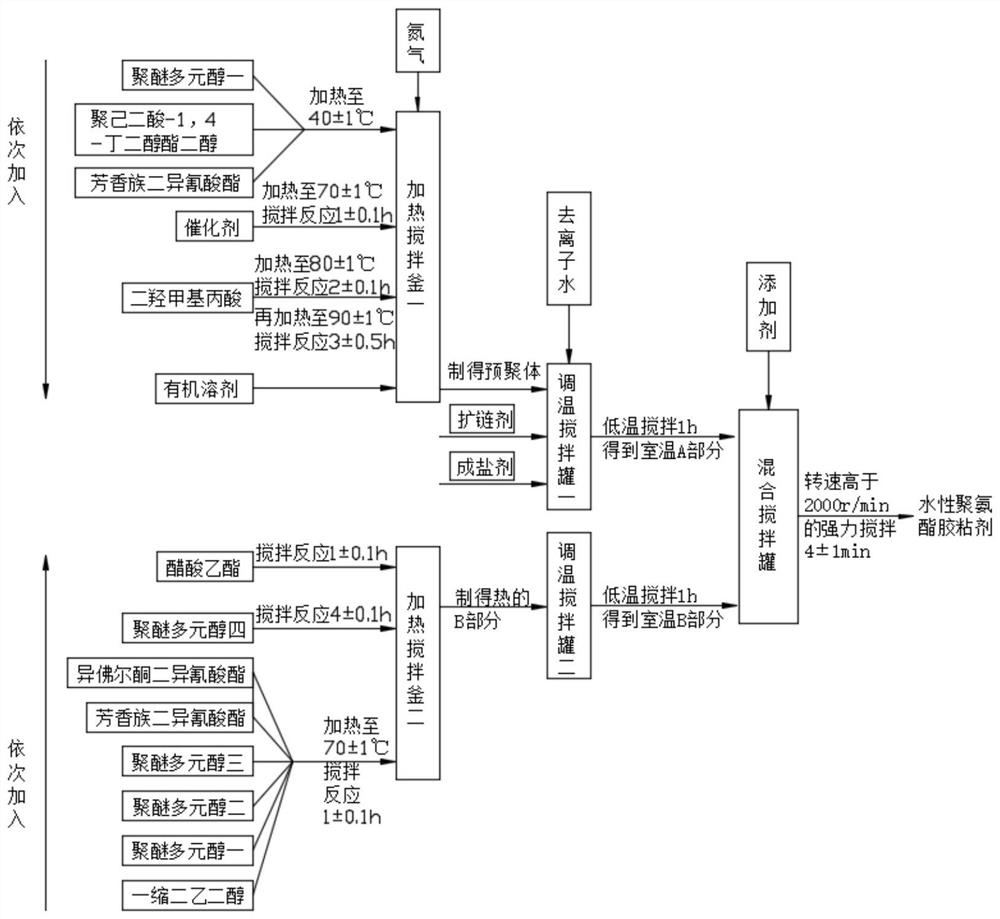

Method used

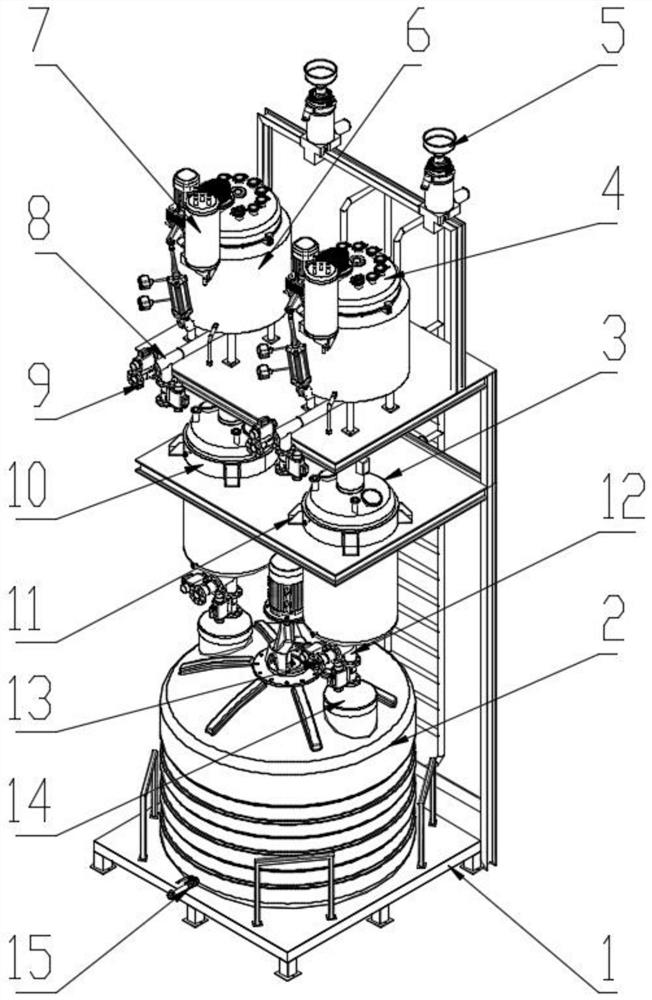

Image

Examples

Embodiment 1

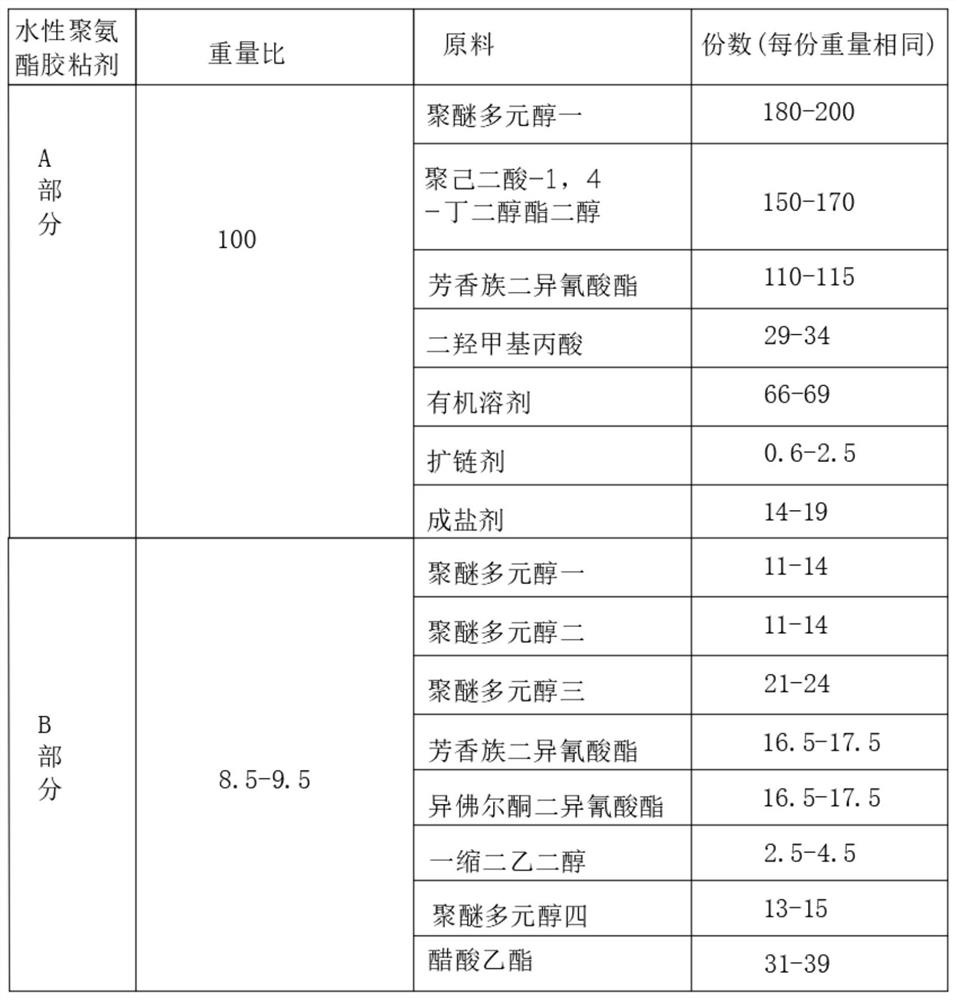

[0079] A water-based polyurethane adhesive is prepared by mixing part A and part B in a ratio of parts by weight of 100:9, and part A is made from raw materials in parts by weight of the following components: 115 parts of aromatic diisocyanate, 115 parts of polyether polyol 200 parts of alcohol one, 170 parts of poly-1,4-butanediol adipate diol, 34 parts of dimethylolpropionic acid, 19 parts of salt-forming agent, 2.5 parts of chain extender, 69 parts of organic solvent (each the same weight);

[0080] Part B is made from raw materials in parts by weight of the following components: 17.5 parts of aromatic diisocyanate, 17.5 parts of isophorone diisocyanate, 14 parts of polyether polyol one, 14 parts of polyether polyol two, polyether polyol 24 parts of polyol 3, 15 parts of polyether polyol 4, 4.5 parts of diethylene glycol, 39 parts of ethyl acetate (each part has the same weight);

[0081] In step 1, the aromatic diisocyanate, polyether polyol 1 and poly-1,4-butanediol adip...

Embodiment 2

[0088] A water-based polyurethane adhesive is prepared by mixing part A and part B in a ratio of parts by weight of 100:9, and part A is made from raw materials in parts by weight of the following components: 115 parts of aromatic diisocyanate, 115 parts of polyether polyol 200 parts of alcohol one, 170 parts of poly-1,4-butanediol adipate diol, 34 parts of dimethylolpropionic acid, 19 parts of salt-forming agent, 2.5 parts of chain extender, 69 parts of organic solvent (each the same weight);

[0089] Part B is made from raw materials in parts by weight of the following components: 17.5 parts of aromatic diisocyanate, 17.5 parts of isophorone diisocyanate, 14 parts of polyether polyol one, 14 parts of polyether polyol two, polyether polyol 24 parts of polyol 3, 15 parts of polyether polyol 4, 4.5 parts of diethylene glycol, 39 parts of ethyl acetate (each part has the same weight);

[0090] Step 1, according to the weight parts of each component, add aromatic diisocyanate, p...

Embodiment 3

[0096] A polyurethane adhesive is prepared from the raw materials in parts by weight of the following components: 38 parts of castor oil, 11.75 parts of toluene diisocyanate, 49.75 parts of styrene, and 0.5 parts of dibenzoyl peroxide. When the stirring device is controlled at 20-80 DEG C, the mixture is melted and mixed evenly to prepare the polyurethane adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap