Flexible assembly line for transformer clamps

A transformer clamp and assembly line technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of poor coating quality, low production and processing efficiency of transformer clamps, and many processes, and achieve enhanced coating Improve quality, reduce manual loading, and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

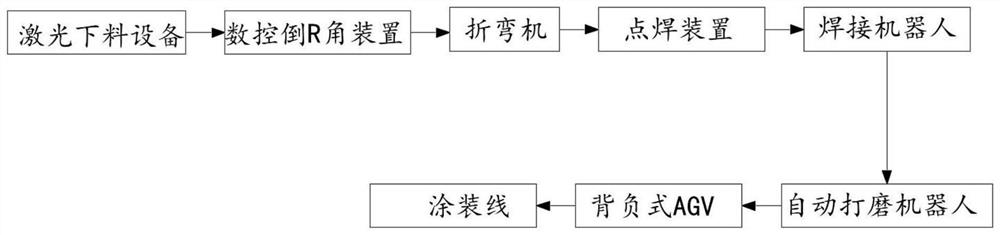

[0024] see figure 1 As shown, the present invention is a flexible assembly line for transformer clips, including laser cutting equipment for cutting transformer clips, a bending machine for transformer clips, a spot welding device for preliminary positioning and fixing, and a In the welding robot for automatic grasping, splicing and welding of transformer clips, knapsack AGV for finished product transfer, and coating line for transformer clip painting, various plates in the spot welding device are positioned on the profiles by spot welding. Preliminary positioning and fixing; automatic grasping and spot welding by welding robots, high dimensional accuracy and stable welding quality; automatic spot welding to complete spot welding, precise and uniform position, and high quality; The coating line includes a pair of transformer clips The dipping line or powder spraying room for the finished product to be dipped or dry powder sprayed, the drying device for drying transformer clips...

Embodiment 2

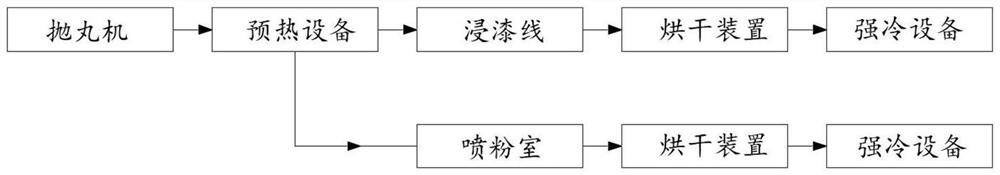

[0029] On the basis of the above Embodiment 1, please refer to figure 2 As shown, a shot blasting machine for surface treatment of the finished transformer clip is also provided in front of the paint dipping line or the powder spraying chamber. There is also a preheating device between the shot blasting machine and the dipping line or the powder spraying room. The preheating temperature is kept at 35°C-50°C, which can reduce the temperature difference between the coating and the substrate, and is beneficial to improve the bonding strength of the coating. , so that the coating is not easy to crack; and preheating can remove moisture and activate the surface, which is conducive to the combination of the coating and the substrate, and control the expansion of the substrate relative to the coating; and preheating can better enhance the coating quality.

[0030] see figure 2 As shown, the dipping line includes a dipping chamber body, a leveling chamber and a dipping tank. Throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com