Multifunctional composite additive for X-Pave ultrathin pavement as well as preparation and use methods of multifunctional composite additive

A compound additive and multi-functional technology, applied in the field of road paving materials, can solve the problems of unfavorable small-scale maintenance projects, complex production and use processes, etc., and achieve the effects of improving anti-stripping performance, reducing raw material costs, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

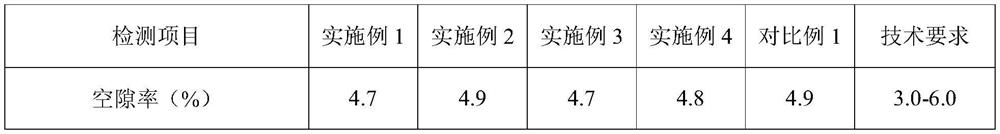

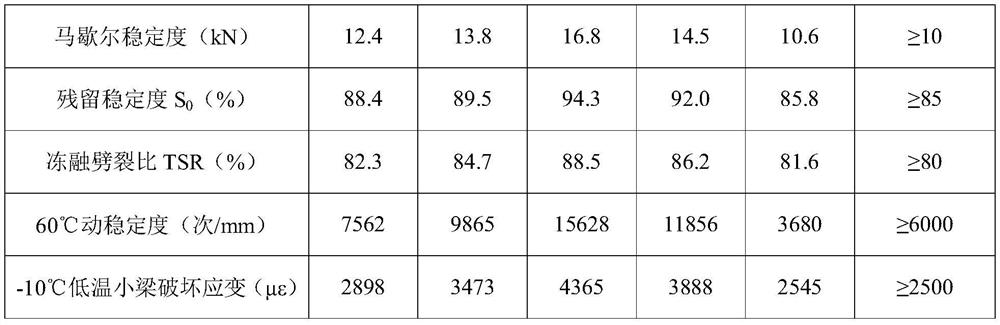

Examples

Embodiment 1

[0049] (1) first weigh 200g of regenerated LDPE particles, 100g of chopped basalt fiber surface-treated with 3mm silane coupling agent and mix in a high-speed mixer, the mixing time is 3min, and extrude and granulate to obtain blend A, The screw feed temperature was 120°C, the melt processing temperature was 160°C, and the pelletizing die temperature was 140°C.

[0050] (2) Weigh 100g SBS, 200g regenerated TPR, 50g aromatic hydrocarbon-based rubber oil respectively, after mixing 3min in the high-speed mixer, add 150g stearic acid amide and the blend A prepared by the above step (1), and then After stirring and mixing for 5 minutes, it was added to the feeding funnel of the twin-screw extruder for extrusion and granulation. Then, the multifunctional composite additive 1 for X-Pave ultra-thin pavement was obtained.

[0051] Application of X-Pave multifunctional composite additive for ultra-thin pavement 1:

[0052] S1. Heat the I-D modified asphalt to 160°C, according to the X...

Embodiment 2

[0058] (1) Weigh 300g of regenerated LDPE particles and 120g of chopped polyester fibers surface-treated with 6mm silane coupling agent, respectively, and mix them in a high-speed mixer. The mixing time is 3min, and extrude and granulate to obtain blend A. , the screw feeding temperature is 140 ℃, the melt processing temperature is 180 ℃, and the pelletizing die temperature is 150 ℃.

[0059] (2) Weigh 200g SBS, 200g regenerated TPR, 80g naphthenic rubber oil respectively, after mixing 4min in the high-speed mixer, add 200g erucamide and the blend A prepared in the above step (1), and then add After stirring and mixing for 5 minutes, it was added to the feeding funnel of the twin-screw extruder for extrusion and granulation. Then, the multifunctional composite additive 2 for X-Pave ultra-thin pavement was obtained.

[0060] Application of X-Pave Multifunctional Compound Additive 2 for Ultra-thin Pavement:

[0061] S1. Heat the I-D modified asphalt to 165°C. According to the ...

Embodiment 3

[0065] (1) Weigh 400g of regenerated LDPE particles and 150g of chopped glass fibers surface-treated with 6mm silane coupling agent, respectively, and mix them in a high-speed mixer. The mixing time is 4min, and extrude and granulate to obtain blend A. The screw feed temperature was 140°C, the melt processing temperature was 180°C, and the pelletizing die temperature was 150°C.

[0066] (2) Weigh 300g of SBS, 100g of regenerated TPR, 100g of paraffin-based rubber oil respectively, mix them in a high-speed mixer for 5min, then add 200g of oleic acid amide and the blend A prepared in the above step (1), and then carry out After stirring and mixing for 5 minutes, it was added to the feeding funnel of the twin-screw extruder for extrusion and granulation. The multifunctional composite additive 3 for X-Pave ultra-thin pavement was obtained.

[0067] Application of X-Pave Multifunctional Compound Additive 3 for Ultra-thin Pavement:

[0068] S1. Heat the I-D modified asphalt to 165...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com