A kind of low-viscosity rubber powder modified asphalt and preparation method thereof

A modified asphalt, low-viscosity technology, used in building components, building insulation materials, plastic recycling, etc., can solve the problems of inability to achieve catalytic activation effect, complex activated rubber powder process, affecting low-temperature performance of asphalt, etc. Low temperature performance and storage stability, alleviating black pollution, increasing the effect of high temperature anti-rutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

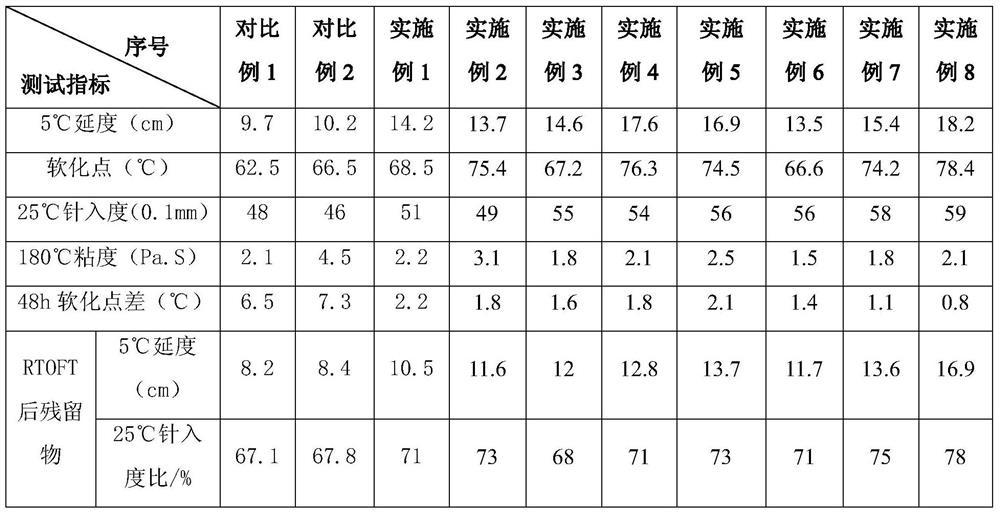

Examples

Embodiment 1

[0043] Mix 36-mesh waste tire rubber powder, pine tar, tall oil, thiophenol, and aromatic disulfide in a mass ratio of 100:3:2:0.2:0.1, add it to a high-speed mixer for premixing, and stir for premixing The time is 10 minutes, and the rubber powder mixture is prepared; the rubber powder mixture is passed through the conveyor belt and enters the microwave activation processor, the microwave radiation power is 400W, and the radiation time is 1.5min, and the modified rubber powder 1 is obtained through catalytic activation.

[0044] Rapidly heat the base asphalt to 185-190°C, stir and add modified rubber powder 1 which accounts for 25% by mass of the base asphalt, keep warm and pre-mix for 15 minutes in the premixing tank, then grind it through a colloid mill, and then enter The mixing and development tank was kept warm for 3 hours, and finally the cross-linking agent accounting for 0.25% by mass of the base asphalt was slowly added, and the low-viscosity rubber powder modified as...

Embodiment 2

[0046] The base asphalt is rapidly heated to 185-190°C through a heat exchanger, and the modified rubber powder 1 in Example 1, which accounts for 30% by mass of the asphalt, is stirred and added thereto, and is kept warm and premixed for 15 minutes in a premixing tank, and then Grind once with a colloid mill, then enter the stirring development tank for 3 hours of heat preservation and development, and finally slowly add a crosslinking agent accounting for 0.25% of the base asphalt mass percentage, and continue heat preservation and stirring for 1 hour to obtain low-viscosity rubber powder modified asphalt. its performance.

Embodiment 3

[0048] Mix 36-mesh waste tire rubber powder, coal tar, tall oil, rosin, thiophenol zinc salt, and polyalkylphenol sulfide in a mass ratio of 100:2:4:4:0.5:0.5, and add to high-speed mixing Machine for premixing, mixing premixing time is 10 minutes, the rubber powder mixture is obtained; the rubber powder mixture enters the microwave activation processor through the conveyor belt, the microwave radiation power is 600W, the radiation time is 4.0min, and it is obtained through catalytic activation. Modified rubber powder 2.

[0049] Rapidly heat the base asphalt to 185-190°C, stir and add modified rubber powder 2 accounting for 25% by mass of the asphalt, keep warm and pre-mix for 15 minutes in the premixing tank, then grind it through a colloid mill, and then enter the mixing process The development tank was kept warm for 3 hours, and finally the cross-linking agent accounting for 0.3% by mass of the base asphalt was slowly added, and the heat preservation and stirring was conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com