Monocrystalline silicon wafer cleaning machine and method for cleaning monocrystalline silicon wafer

A single-crystal silicon wafer and cleaning machine technology, which is applied to cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc. Problems such as lack of optimization strategy for spray pressure and temperature regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

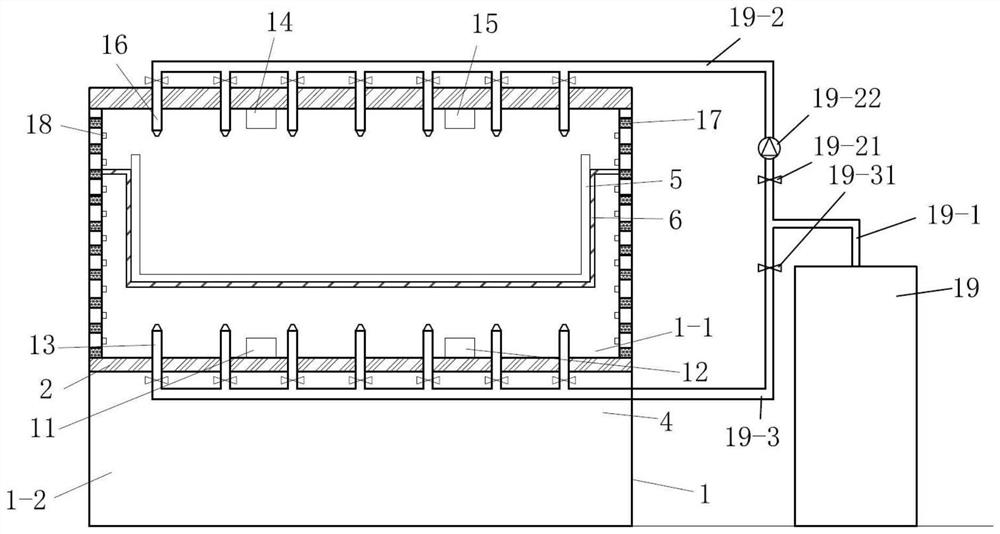

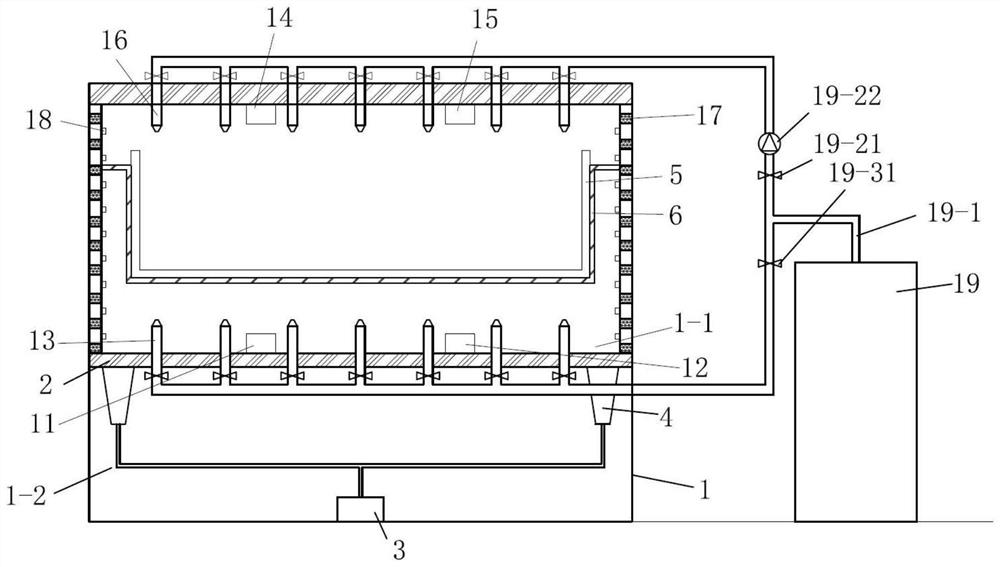

[0075] like figure 1 As shown in the figure, a single crystal silicon wafer cleaning machine provided by the present invention includes a body 1, and a partition 2 is horizontally placed inside the body 1 to divide the body 1 into an upper body 1-1 and a lower body 1-2. The upper body 1 -1 a plurality of cleaning baskets 5 are arranged above the partition plate 2, and the plurality of cleaning baskets 5 are arranged in the cleaning basket placement groove 6 in sequence;

[0076] The lower part of the cleaning basket placement tank 6 is provided with a lower laser transmitter 11, a lower laser receiver 12 and a number of lower shower heads 13 arranged at even intervals. Several upper shower heads 16 are arranged at intervals; the inner layer of the side wall of the upper body 1-1 surrounds the heating pipe 17 and the inside of the upper body 1-1 is surrounded by a temperature sensor 18; a number of lower shower heads 13 and a number of upper The shower heads 16 are all communi...

Embodiment 2

[0081] On the basis of Embodiment 1, as a preferred embodiment of the present invention, the body of the single crystal silicon wafer cleaning machine provided by the present invention is cylindrical.

Embodiment 3

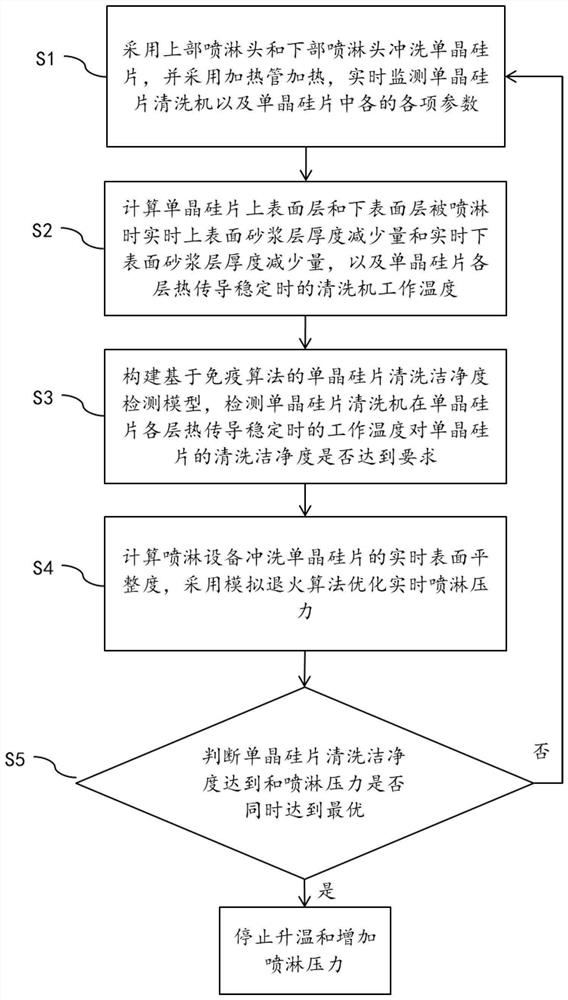

[0083] like image 3 As shown, it is a cleaning method of a single crystal silicon wafer cleaning machine provided by the present invention, comprising the following steps:

[0084] S1: Use several upper shower heads 13 and several lower shower heads 16 to rinse the single crystal silicon wafer, use the heating tube 17 to heat the body 1 and its internal water environment during the washing process, and monitor the i-th single crystal silicon wafer in real time. Working temperature of cleaning machine at all times Washing machine water temperature The temperature of each silicon layer in the single crystal silicon wafer, the distance h of the mortar particles moved by the spray on the upper surface of the single crystal silicon wafer from the initial upper surface without being washed 上,i and the distance h of the mortar particles on the lower surface being sprayed and moving from the initial lower surface position that was not washed 下,i , the velocity v of the mortar pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com