Cartilage acellular matrix and preparation method thereof

A decellularized matrix and decellularized technology, applied in the field of cartilage decellularized matrix and its preparation, can solve the problems of tissue collapse, refractory degradation, slow degradation, etc., and achieve the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

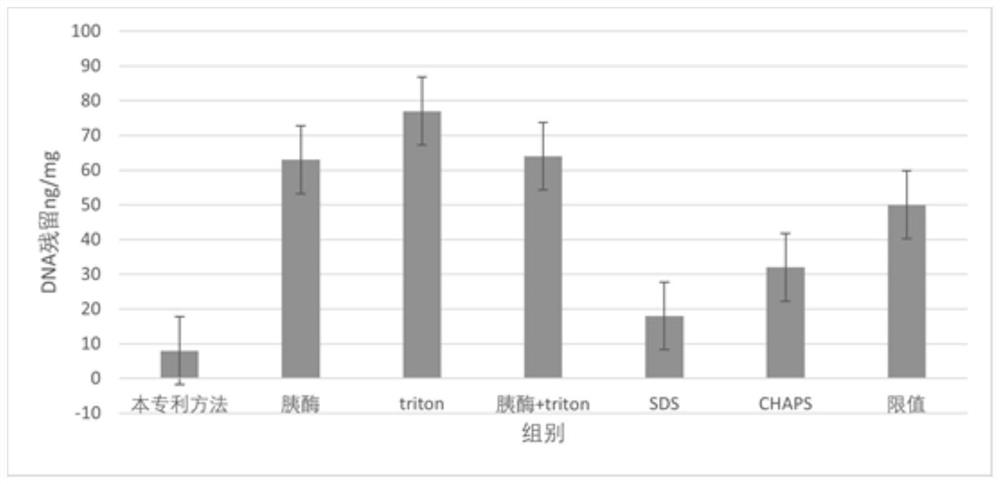

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] In order to obtain the cartilage acellular matrix without destroying the structure of the cartilage itself, the present invention provides a preparation method of the cartilage acellular matrix, the preparation method comprising the following steps:

[0036] S1: take mammalian cartilage, pretreat the cartilage to obtain clean cartilage;

[0037] S2: Treat the clean cartilage with an enzyme solution to open the pore structure of the clean cartilage surface to obtain the cartilage material A;

[0038] S3: using a non-ionic reagent to remove the cell components in the superficial layer of the cartilage material A to obtain the cartilage material B;

[0039] S4: using an ionic reagent to preliminarily remove the cellular components in the deep layer of the cartilage material B to obtain the cartilage material C;

[0040] S5: using a zwitterionic reagent to remove the cell components in the deep layer of the cartilage material C twice to obtain the cartilage material D;

...

Embodiment 1

[0075] The present embodiment provides a method for preparing a cartilage acellular matrix, comprising the following steps:

[0076] S1: Take porcine rib cartilage, use a scalpel to remove the flesh on the cartilage surface, scrape the periosteum on the rib cartilage surface, and obtain a white cartilage material without any fleshy residue and pale pink periosteum on the surface; purified water was used for the obtained cartilage material. For cleaning, first use running water to rinse the cartilage until the cartilage is clean, then use purified water to shake and clean the cartilage material 4 times for 30 minutes each time at 37°C, a material-liquid ratio of 1:10, and a rotational speed of 200 r in an air-bath constant temperature shaking box. get clean cartilage;

[0077] S2: Digest clean cartilage with trypsin solution with a mass concentration of 1%, shake for 8 hours in an air bath constant temperature shaking box at 37° C., under the conditions of a solid-liquid ratio ...

Embodiment 2

[0088] The present embodiment provides a method for preparing a cartilage acellular matrix, comprising the following steps:

[0089] S1: Take the bovine rib cartilage, use a scalpel to remove the flesh on the cartilage surface, scrape the periosteum on the surface of the rib cartilage, and obtain a white cartilage material without any fleshy residue and pale pink periosteum residue on the surface; purified water was used to carry out the obtained cartilage material. For cleaning, first use running water to rinse the cartilage until the cartilage is clean, then use purified water to shake and clean the cartilage material 4 times for 30 minutes each time at 37°C, a material-liquid ratio of 1:10, and a rotational speed of 200 r in an air-bath constant temperature shaking box. get clean cartilage;

[0090] S2: Use a trypsin solution with a mass concentration of 1% to digest the clean cartilage, and shake it for 12 hours in an air-bath constant temperature shaking box at 37° C., a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com