Preparation method and application of urea PDI polymer/MoS2 catalyst

A polymer and catalyst technology, applied in the field of composite photocatalyst preparation, can solve the problems of insufficient mass production, increased specific surface area of materials, increased active sites, etc., and achieves the effects of low cost, large output and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

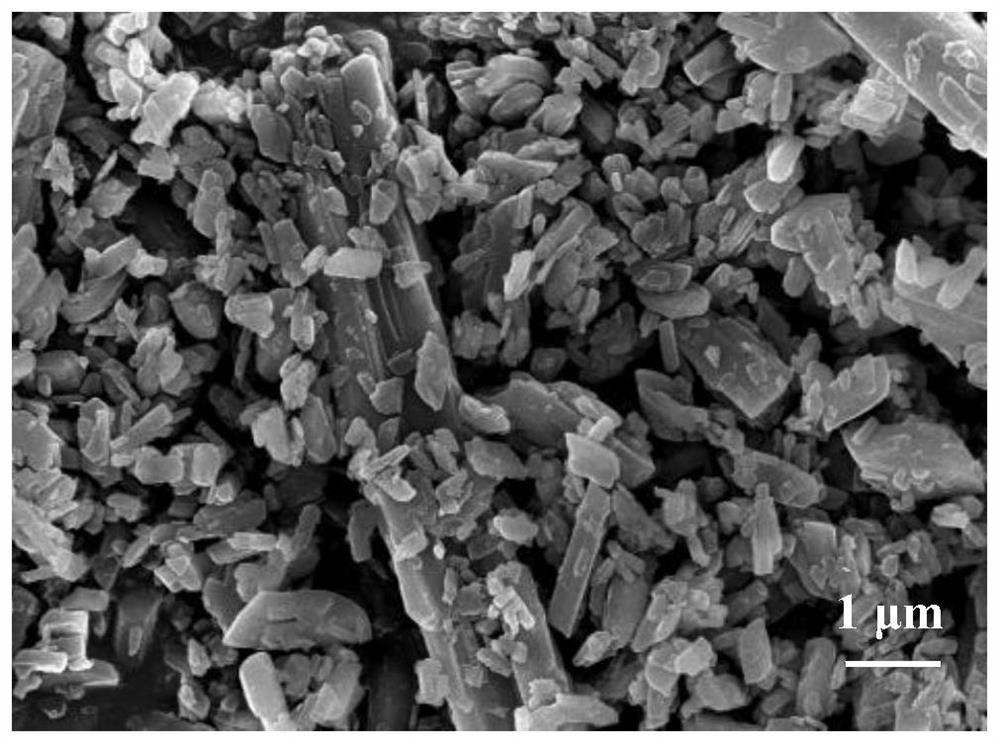

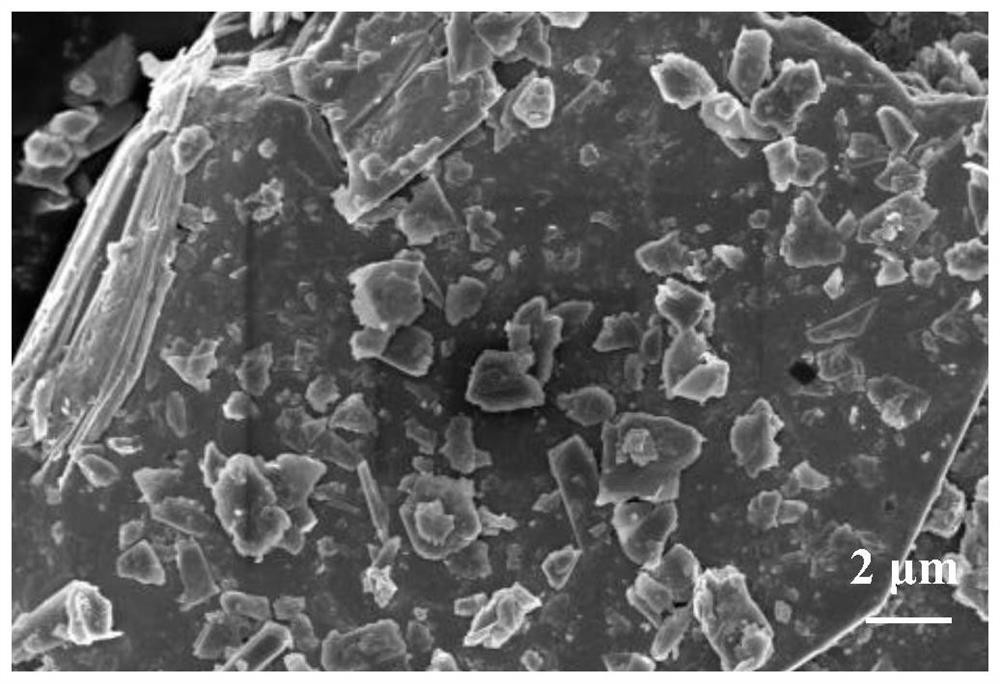

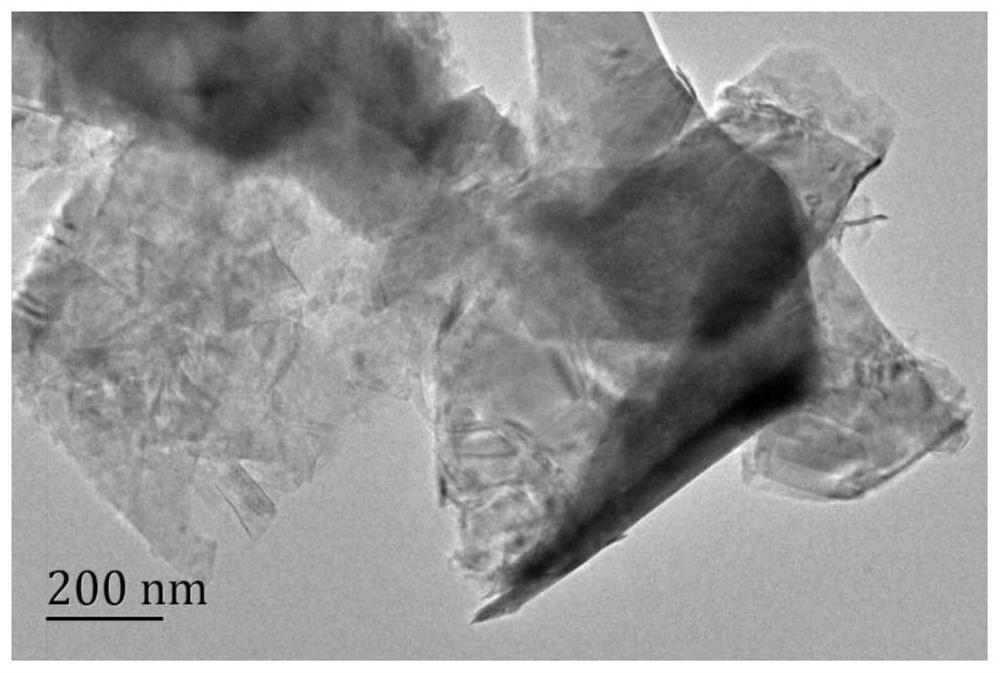

Image

Examples

Embodiment 1

[0024] Urea PDI polymer / MoS of this example 2 The preparation method of catalyst, comprises the steps:

[0025] (1) Put urea, perylene-3,4,9,10-tetracarboxylic dianhydride, anhydrous zinc acetate and imidazole in an atmosphere of 1:6.5:3.08:41.67 in a mass ratio of 140 °C in four The necked flask is used for organic synthesis, hydrochloric acid is added and stirred to obtain a stirred product;

[0026] (2) Filtration, washing to neutrality and drying of the stirred product to obtain urea PDI polymer powder, wherein the filtration membrane pore size is 0.22 μm, and the drying temperature is 60 °C;

[0027] (3) MoS with a mass ratio of 1:1 2 Put the urea-PDI polymer into the ball mill in the steel container for 45min to obtain the product ball-milled urea-PDI polymer / MoS 2 Composite photocatalyst, denoted as UM-45;

[0028] Urea PDI polymer / MoS obtained by the preparation method 2 The catalyst can be applied to degrade tetracycline in water, and the steps are as follows:

...

Embodiment 2

[0031] Urea PDI polymer / MoS of this example 2 The preparation method of catalyst, comprises the steps:

[0032] (1) Put urea, perylene-3,4,9,10-tetracarboxylic dianhydride, anhydrous zinc acetate and imidazole in an air atmosphere at a temperature of 110 °C in four The necked flask is used for organic synthesis, hydrochloric acid is added and stirred to obtain a stirred product;

[0033] (2) Filtration, washing to neutrality and drying of the stirred product to obtain urea PDI polymer powder, wherein the filtration membrane pore size is 0.22 μm, and the drying temperature is 50 °C;

[0034] (3) MoS with a mass ratio of 1:1.5 2 Put the urea-PDI polymer into the ball mill in the steel container for 30min to obtain the product ball-milled urea-PDI polymer / MoS 2 Composite photocatalyst, denoted as UM-30;

[0035] Urea PDI polymer / MoS obtained by the preparation method2 The catalyst can be applied to degrade tetracycline in water, and the steps are as follows:

[0036] Take ba...

Embodiment 3

[0038] Urea PDI polymer / MoS of this example 2 The preparation method of catalyst, comprises the steps:

[0039] (1) Put urea, perylene-3,4,9,10-tetracarboxylic dianhydride, anhydrous zinc acetate and imidazole in an air atmosphere at a temperature of 120 ℃ in four The necked flask is used for organic synthesis, hydrochloric acid is added and stirred to obtain a stirred product;

[0040] (2) Filtration, washing to neutrality and drying of the stirred product to obtain urea PDI polymer powder, wherein the filtration membrane pore size is 0.45 μm, and the drying temperature is 60 °C;

[0041] (3) MoS with a mass ratio of 1:0.7 2 Put the urea-PDI polymer into the ball mill in the steel container for 60min to obtain the product ball-milled urea-PDI polymer / MoS 2 Composite photocatalyst, denoted as UM-60;

[0042] Urea PDI polymer / MoS obtained by the preparation method 2 The catalyst can be applied to degrade tetracycline in water, and the steps are as follows:

[0043] Take b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com