Method for retaining ammonia nitrogen by using polylysine in biological sewage treatment process

A sewage biological treatment, polylysine technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, animal husbandry wastewater treatment, etc., can solve the case of sewage treatment without natural ammonia oxidation inhibitors etc. to achieve the effects of easy operation, simple process, good stability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

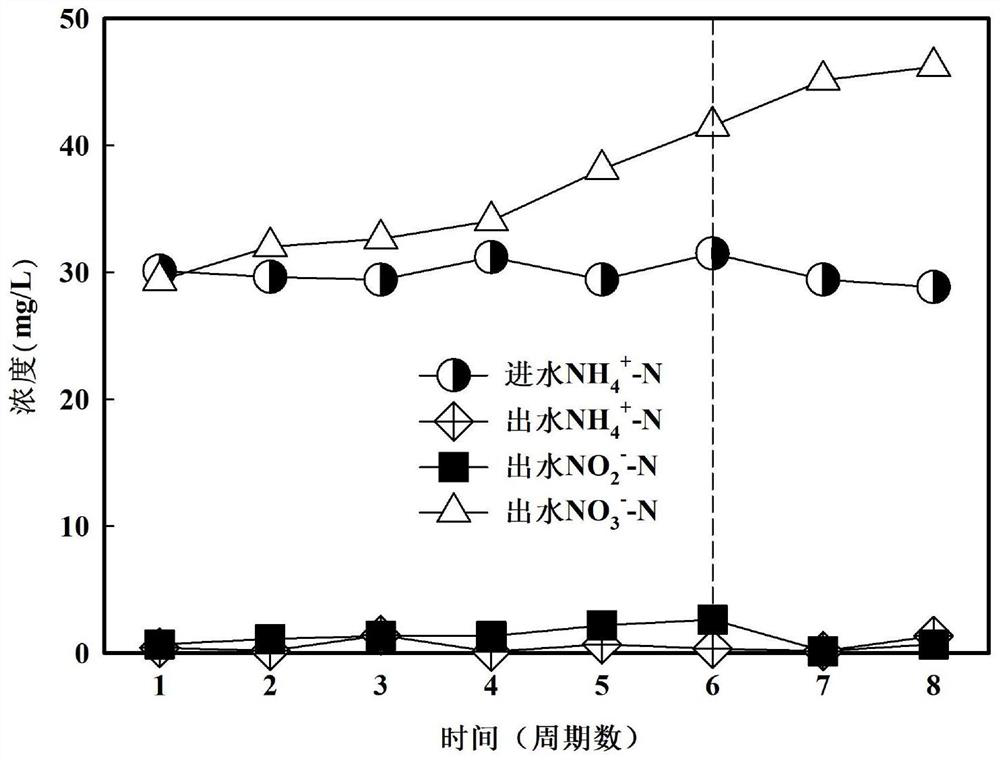

[0034] The seed sludge of the embodiment of the present invention is the flocculent sludge with nitrification activity in an urban sewage treatment plant in Beijing, and the influent water quality index is NH 4+ -N≈56mg / L, NO 2 - -N≈0mg / L, NO 3 - -N≈0mg / L.

[0035] The activated sludge was placed in a 1L reactor, and the sludge concentration was about 3000mg / L. The activated sludge was cleaned three times to eliminate the interference of some impurities in the reactor. Then, only one polylysine soaking treatment was performed on the activated sludge, and the prepared polylysine stock solution was added to the reactor to maintain the concentration at about 400 mg / L, and the soaking treatment was carried out for 6 hours. During this period, use The stirring device stirs to ensure that the activated sludge and the drug are fully mixed and contacted. After soaking, the activated sludge was washed three times to remove residual polylysine, and then the reactor was operated in...

Embodiment 2

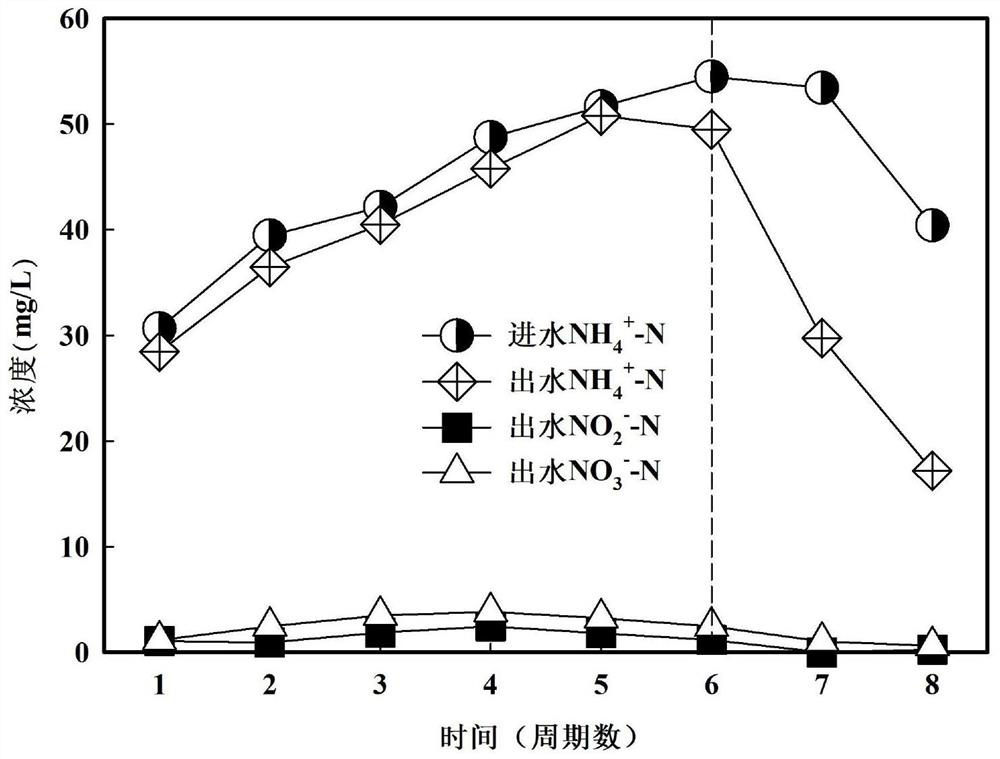

[0038] The seed sludge of the embodiment of the present invention is the biofilm sludge with nitrification activity in a city sewage treatment plant in Beijing, and the influent water quality index is NH 4 + -N≈75mg / L, NO 2 - -N≈28mg / L, NO 3 - -N≈0mg / L, COD≈100mg / L.

[0039] The packing with biofilm was placed in a 1L reactor, and the amount of biofilm was about 5000 mg / L. The activated sludge was cleaned three times to eliminate the interference of some impurities in the reactor. Then, only one poly-lysine immersion treatment was performed on the biofilm sludge, and the prepared poly-lysine stock solution was added to the reactor to maintain its concentration at about 500 mg / L, and the immersion treatment was carried out for 10 hours. During this period Use a stirring device to stir to ensure that the biofilm sludge and the drug are fully mixed and contacted. After soaking, the biofilm sludge was cleaned three times to remove residual polylysine, and then the reactor w...

Embodiment 3

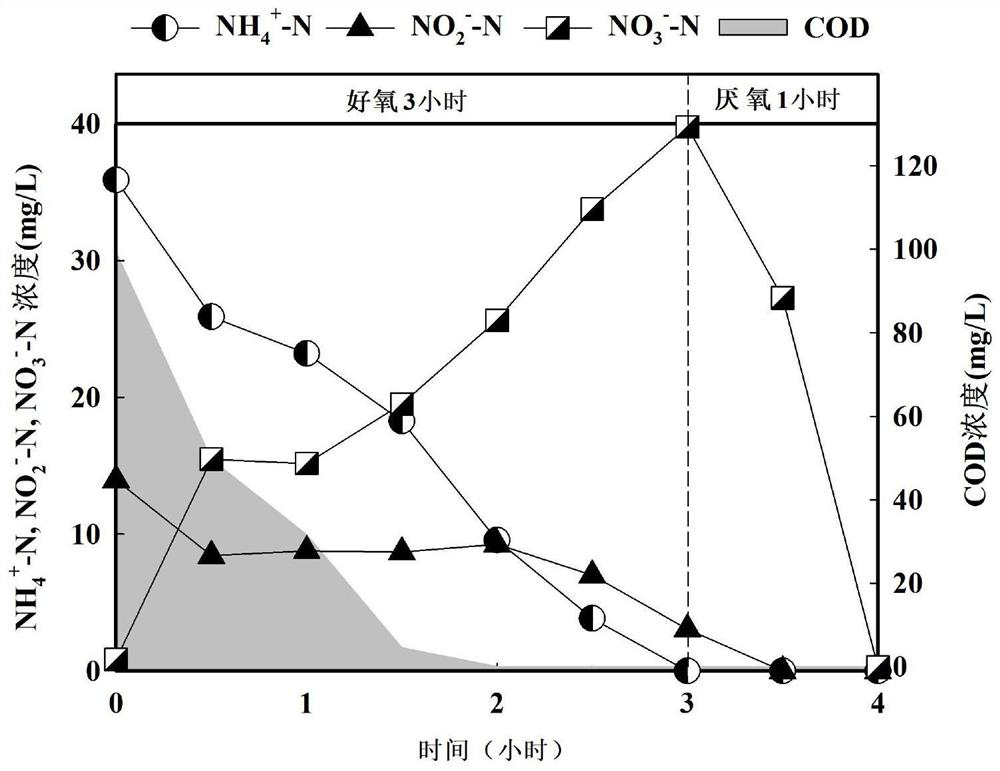

[0042] The seed sludge of the embodiment of the present invention is activated sludge with nitrification activity in a certain MBR process, and the influent water quality index is NH 4 + -N≈150mg / L, NO 2 - -N≈0mg / L, NO 3 - -N≈0mg / L.

[0043] The activated sludge was placed in a 1L reactor, and the sludge concentration was about 10,000 mg / L. The activated sludge was cleaned three times to eliminate the interference of some impurities in the reactor. Then, only one polylysine soaking treatment was performed on the activated sludge, and the prepared polylysine stock solution was added to the reactor to maintain the concentration at about 500 mg / L, and the soaking treatment was carried out for 30 hours. During this period, use The stirring device stirs to ensure that the activated sludge and the drug are fully mixed and contacted. After soaking, the activated sludge was washed three times to remove residual polylysine, and then the reactor was operated in the mode of water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com