Biological denitrification method coupled with iron flocculation process

A technology of biological denitrification and flocculation process, applied in the field of biological denitrification, can solve the problems of limiting the abundance and activity of Feammox functional bacteria and denitrification efficiency, restricting the large-scale application of Feammox process, and poor bioavailability, so as to achieve easy transformation and upgrading , good universality and operability, no need for carbon source effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

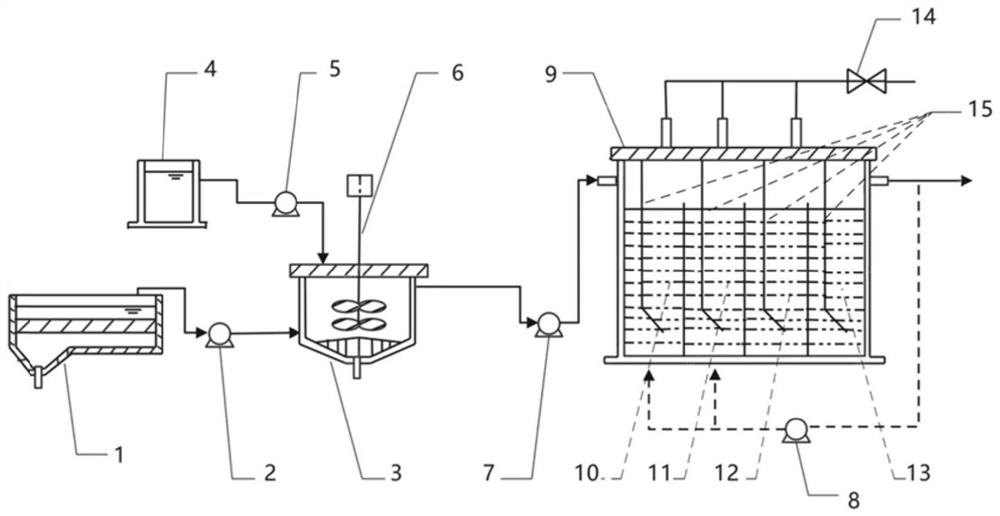

[0043] The present embodiment has carried out a deep denitrification treatment for urban sewage, as follows:

[0044] Take the secondary biological treatment effluent of a city sewage plant for test, its total phosphorus content is 3.12mg / L, ammonia nitrogen is 2.53mg / L, nitrate nitrogen content is 9.27mg / L, and COD is 21mg / L. Use the biological denitrification method proposed by the present invention to carry out deep denitrification, the details are as follows:

[0045] (1) Iron flocculation: Using ferrous sulfate as the flocculant, the dosage is 90mg / L, and the flocculation treatment process is completed by fast stirring (200r / min) for 2min, slow stirring (40r / min) for 15min, and precipitation for 30min. After coagulation treatment, the dissolved oxygen in the effluent is lower than 0.02mg / L, the ORP is -150±50mv, and the Fe(III) concentration is about 8mg / L.

[0046] (2) Biological denitrification: adjust the pH of the water body to 5, and supplement the Fe(III) concentra...

Embodiment 2

[0048] The present embodiment processes the sludge digested liquid of the urban sewage treatment plant, and the details are as follows:

[0049] Take the sludge digested liquid of a city sewage treatment plant, dilute it and use the denitrification method proposed by the present invention to carry out deep denitrification. The specific processing flow is as follows:

[0050] (1) Iron flocculation: Using ferrous sulfate as the flocculant, the dosage is 350mg / L, and the flocculation treatment process is completed by fast stirring (200r / min) for 1.5min, slow stirring (60r / min) for 18min, and precipitation for 35min. After coagulation treatment, the residual Fe(III) concentration in the water is about 25mg / L, the dissolved oxygen concentration is lower than 0.02mg / L, and the ORP is -150±50mv.

[0051] (2) Biological denitrification: adjust the pH of the coagulation effluent to 4.5, and supplement the Fe(III) concentration to about 150mg / L. The first two chambers of the ABR react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com