Method and device for fully automatically and continuously producing methyl nitrite

A methyl nitrite, fully automated technology, used in the preparation of nitrite, chemical instruments and methods, separation methods, etc., can solve problems such as temperature and pressure increase, reaction runaway, easy decomposition, etc., to achieve good economy, easy to use. effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

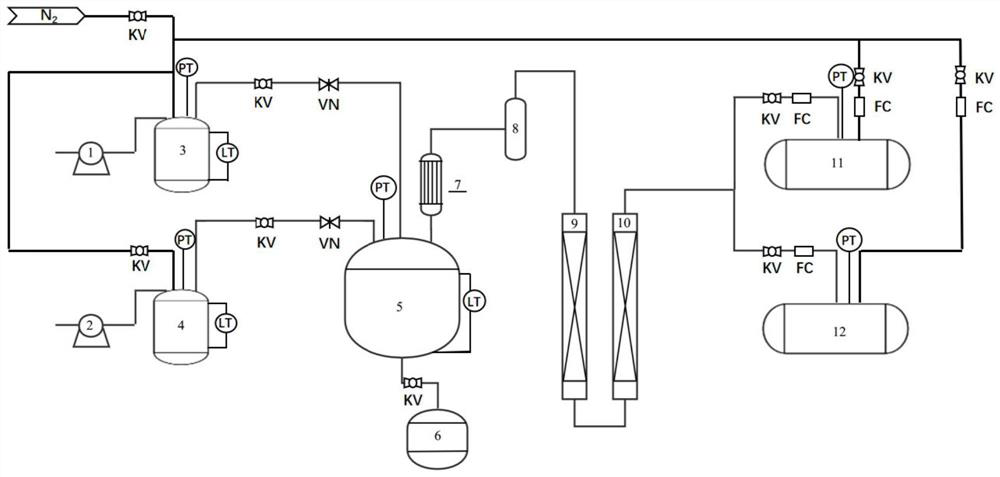

[0121] The device of the present invention consists of 1 and 2 pneumatic diaphragm pumps, 3. mixed raw material storage tank, 4. acid storage tank, 5. reaction kettle, 6. liquid contact tank, 7. reflux condenser, 8. sedimentation tank, 9. molecular sieve Dryer, 10. silica gel filter, 11 and 12. gas storage tank and other equipment and pipelines.

[0122] Wherein the pneumatic diaphragm pump 1 is connected with the mixing raw material tank 3, the mixing raw material tank 3 is connected with the reaction kettle 5 through the flow control unit, the pneumatic diaphragm pump 2 is connected with the acid storage tank 4, and the nitric acid storage tank 4 is connected with the reaction kettle 5 through the flow control unit . The reaction kettle 5 is connected to the liquid contact tank 6 . The reaction kettle 5 is connected through the reflux condenser 7 , the sedimentation tank 8 , the molecular sieve dryer 9 , the silica gel filter 10 , the gas storage tank 11 and the gas storage...

Embodiment 2

[0129] The method utilizing device of the present invention to produce methyl nitrite is:

[0130] 1. Seal the reaction kettle, pass nitrogen and vacuumize for three times;

[0131] 2. Prepare the mixed solution of sodium nitrite and methanol in advance and put it in the raw material barrel;

[0132] 3. Prepare the concentrated nitric acid solution in advance and put it in the raw material barrel;

[0133] 4. Pump acid and mixed solution into mixed raw material tank and acid tank through pneumatic diaphragm pump, and adjust nitrogen pressure in raw material storage tank so that nitrogen pressure is not lower than 0.5MPa;

[0134] 5. Open the pneumatic switch valve, let the mixed raw materials enter the reactor, add 50% of the liquid level of the reactor, and the temperature of the reactor is 20 °C;

[0135] 6. Open the pneumatic switch valve, so that the acid in the acid tank is slowly added to the reaction kettle, and the sodium nitrite and methanol react to generate methyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com