Bisphenol A cyanate ester resin modified polysulfone composite material and preparation method thereof

A type of cyanate ester and composite material technology, which is applied in the field of polymers, can solve the problems of high-temperature dielectric performance stability and poor thermal expansion coefficient, and achieve low dielectric constant, low dielectric loss, and improved glass transition temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

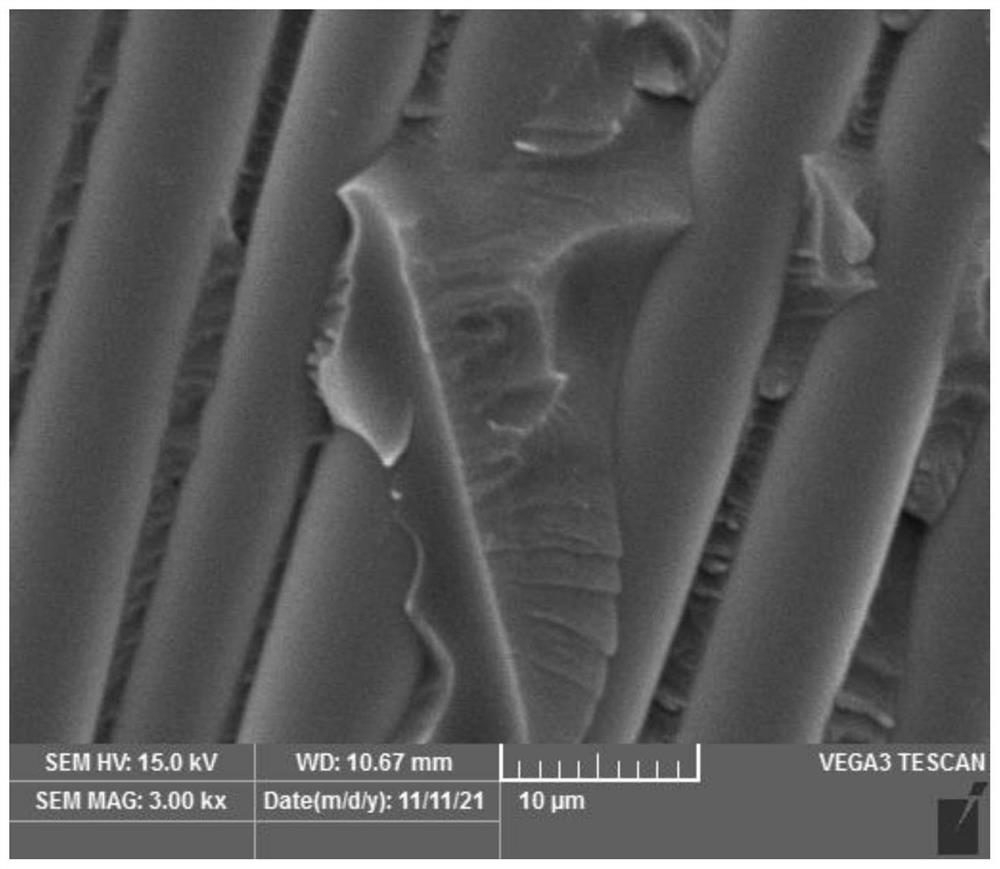

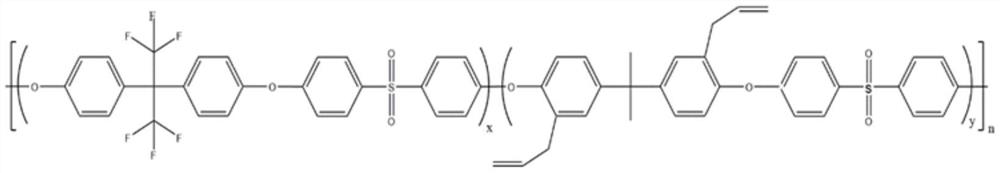

[0031] In step 1, 67.25g of bisphenol AF, 12.34g of allyl bisphenol A and 68.92g of 4,4-dichlorodiphenylsulfone were added to 297.42g of N-methylpyrrolidone in turn to obtain a transparent solution, and 46.07g of carbonic acid was added to the solution. Potassium and 74.36g of toluene were added to the solution in turn, and the dehydration reaction was carried out at a temperature of 160 °C for 2 hours in a three-necked flask equipped with a water separator and nitrogen gas, and then the temperature was raised to 185 °C, all the toluene was evaporated, and the reaction and polymerization were continued for 3 hours. , stop heating, cool down to 120 ℃, pour the product into cold water, stir to precipitate allyl fluorinated polysulfone solid material;

[0032] Step 2, pulverize the allyl fluorinated polysulfone solid material described in step 1, put it into a hydrochloric acid solution with a concentration of 0.84mol / L, let it stand for one day, and filter it with hot water at 90...

Embodiment 2

[0037] In step 1, 67.25g of bisphenol AF, 12.34g of allyl bisphenol A and 68.92g of 4,4-dichlorodiphenylsulfone were added to 297.42g of N-methylpyrrolidone in turn to obtain a transparent solution, and 46.07g of carbonic acid was added to the solution. Potassium and 74.36g of toluene were added to the solution in turn, and the dehydration reaction was carried out at a temperature of 160 °C for 2 hours in a three-necked flask equipped with a water separator and nitrogen gas, and then the temperature was raised to 185 °C, all the toluene was evaporated, and the reaction and polymerization were continued for 3 hours. , stop heating, cool down to 120 ℃, pour the product into cold water, stir to precipitate allyl fluorinated polysulfone solid material;

[0038] Step 2, pulverize the allyl fluorinated polysulfone solid material described in step 1, put it into a hydrochloric acid solution with a concentration of 0.84mol / L, let it stand for one day, and filter it with hot water at 90...

Embodiment 3

[0043]In step 1, 67.25g of bisphenol AF, 12.34g of allyl bisphenol A and 68.92g of 4,4-dichlorodiphenylsulfone were added to 297.42g of N-methylpyrrolidone in turn to obtain a transparent solution, and 46.07g of carbonic acid was added to the solution. Potassium and 74.36g of toluene were added to the solution in turn, and the dehydration reaction was carried out at a temperature of 160°C for 2h in a three-necked flask equipped with a water separator and nitrogen gas, and then the temperature was raised to 185°C, all the toluene was evaporated, and the reaction and polymerization were continued for 3h. , stop heating, cool down to 120 ℃, pour the product into cold water, stir to precipitate allyl fluorinated polysulfone solid material;

[0044] Step 2, pulverize the allyl fluorinated polysulfone solid material described in step 1, put it into a hydrochloric acid solution with a concentration of 0.84mol / L, let it stand for one day, filter it and wash it with hot water 12 times, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com