Scale dissolving cosolvent and preparation method thereof

A technology of co-solvent and scale dissolution, which is applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problems of strong corrosion, weak removal of scale dissolvers, poor universality, etc., and achieve durability Good temperature, increase the scale dissolution rate, reduce the effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

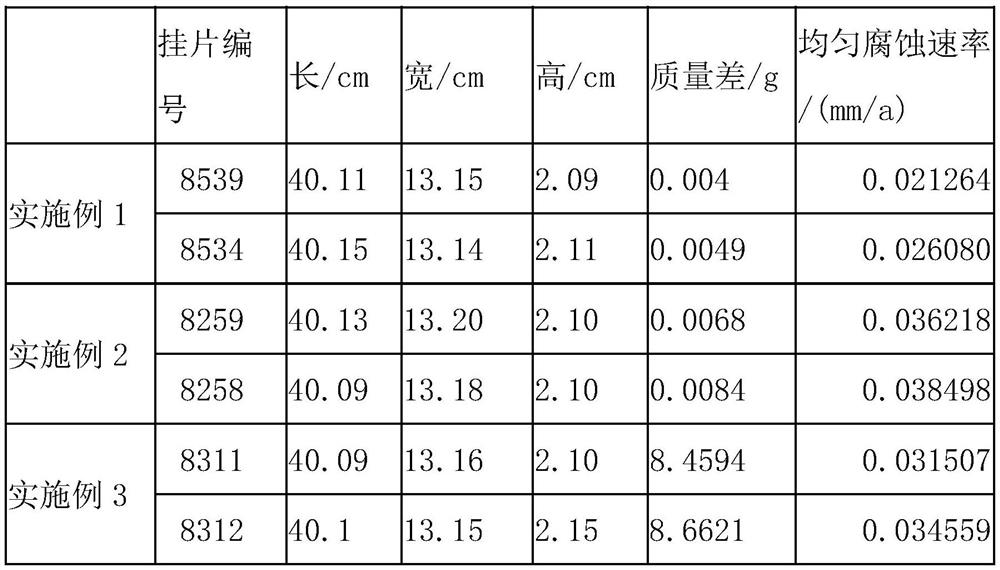

Embodiment 1

[0023] Add 2% organic salt potassium benzoate, 1% organic phenol resorcinol, 0.5% cationic surfactant chlorohexadecylpyridine and 4% chelating agent tetrasodium ethylenediamine tetraacetate in sequence to the container, and the balance water, mix the components, and fully stir at room temperature to obtain 50g of scale solution, the pH value of the solution is 10, respectively add 1g of calcium carbonate and calcium sulfate into the conical flasks with 50mL of scale-dissolving agent, respectively, Stir well. After 1 hour of reaction at room temperature, the calcium sulfate scale dissolution rate reached 98.7%, and after 24 hours of reaction, the calcium carbonate scale dissolution rate was 67.5%.

Embodiment 2

[0025] Add 2.5% organic salt sodium p-toluenesulfonate, 1.5% organic phenol resorcinol, 0.5% cationic surfactant chlorododecyl pyridine, 4% chelating agent tetrasodium EDTA into the container in turn, The remaining amount of water, mix the components, and fully stir at room temperature to obtain 50g of scale-dissolving solution, the pH of the solution is 10.5, and 1g of calcium carbonate and calcium sulfate were added to the conical flasks with 50mL of scale-dissolving agent respectively. , stir well. After 1 hour of reaction at room temperature, the scale dissolution rate of calcium sulfate reached 95.1%, and after 24 hours of reaction, the scale dissolution rate of calcium carbonate was 63.2%.

Embodiment 3

[0027] Add 3% organic salt sodium benzoate, 1.2% organic phenol resorcinol, 0.9% cationic surfactant chlorododecyl pyridine and 4% chelating agent tetrasodium ethylenediamine tetraacetate in sequence to the container, the balance water , Mix the components and stir well at room temperature to obtain 50g of scale-dissolving solution with a pH value of 10.5. Add 1g of calcium carbonate and calcium sulfate to the conical flasks containing 50mL of scale-dissolving agent respectively, and fully Stir. After 1 hour of reaction at room temperature, the calcium sulfate scale dissolution rate reached 98.1%, and after 24 hours of reaction, the calcium carbonate scale dissolution rate was 63.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com