Si-C novel organosilicon quaternary ammonium salt surfactant and preparation method thereof

A technology of organosilicon quaternary ammonium salt and surfactant, which is applied in the field of preparation of quaternary ammonium salt surfactant to achieve the effect of easy separation and purification, simple post-treatment and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

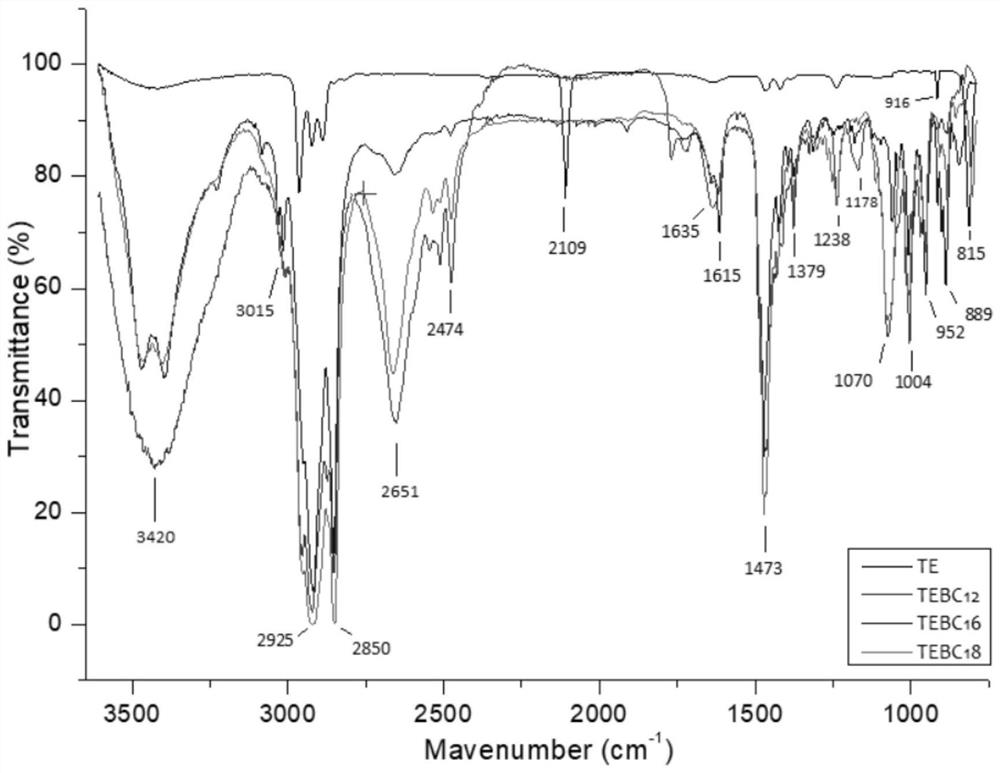

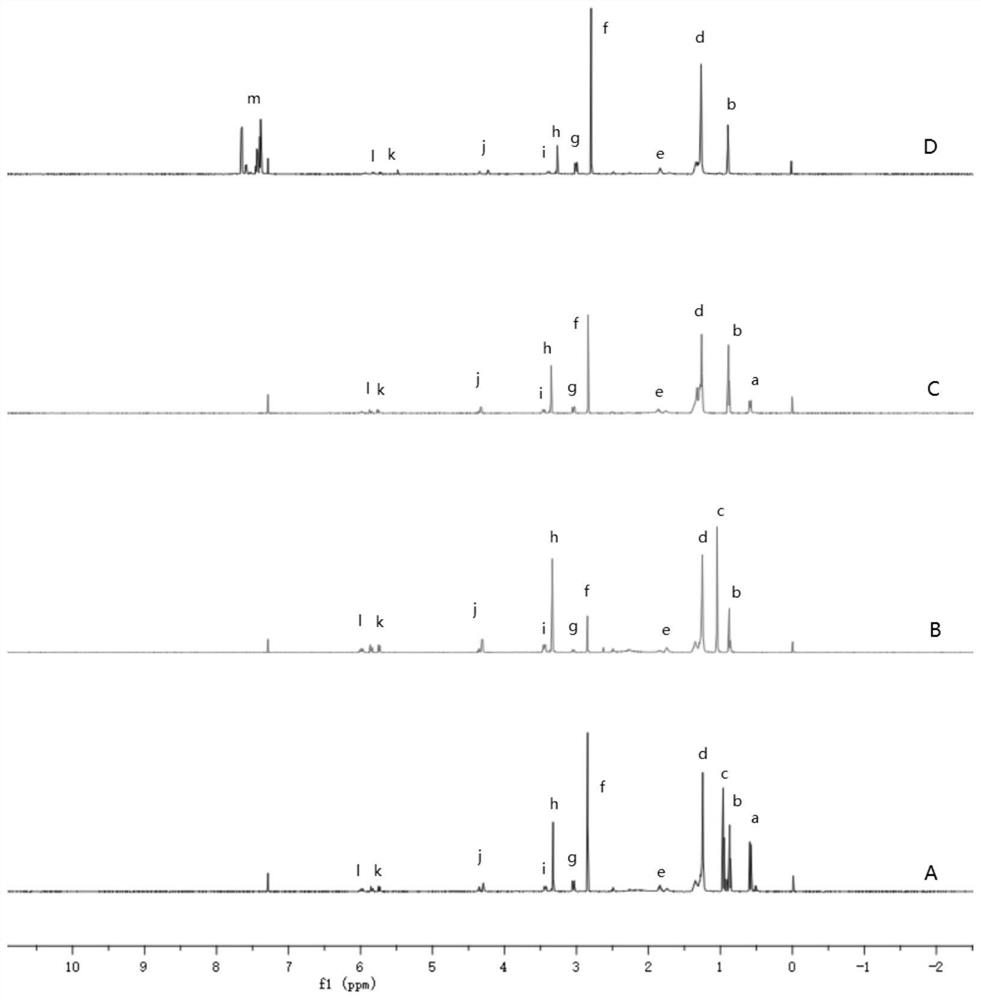

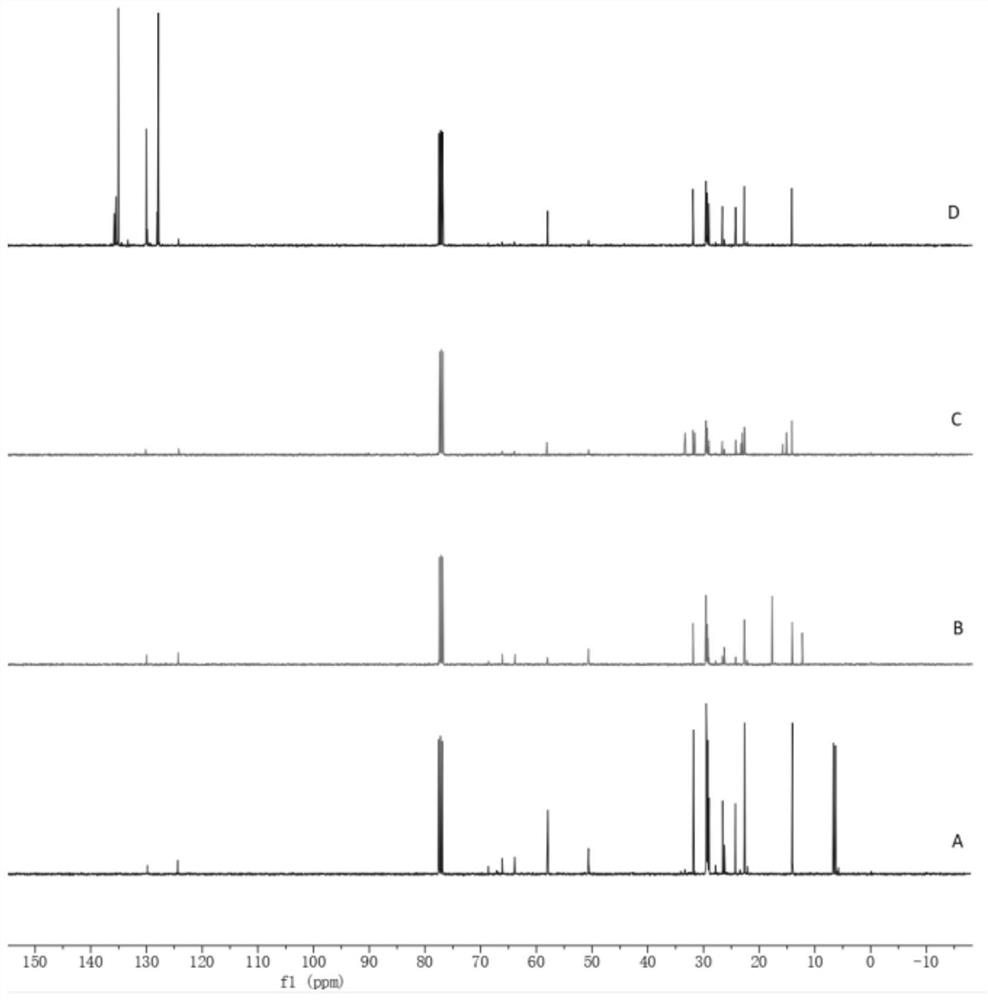

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: prepare organosilicon quaternary ammonium salt surfactant as follows:

[0031] Preparation of chloroplatinic acid catalyst: prepared by dissolving 0.9711 g of chloroplatinic acid in 10 ml of THF treated with distilled water, and stored in a refrigerator before use. Transfer 1.0 mL of this solution to a 100 mL volumetric flask, dilute it to the mark with dry THF, and store at low temperature in the dark after mixing, which can be used for hydrosilation reaction.

[0032] The first step: dimethyl dodecyl allyl ammonium bromide (BC 12 ) preparation:

[0033] A three-necked flask equipped with a thermometer and a reflux condenser was placed in a water bath controlled by a magnetic stirrer, and 40 mL of anhydrous tetrahydrofuran, 8.62 g (0.1 mol) of N,N-dimethylpropenylamine, 24.92 g (0.11 mol) of N-dimethylpropenylamine were added. 1-Bromododecane and 0.33g (0.005mol) zinc powder were reacted at 65°C for 12h, and the reaction was completed. At 45°C, tetrahy...

Embodiment 2

[0036] Embodiment 2: prepare organosilicon quaternary ammonium salt surfactant as follows:

[0037] The first step: dimethyl dodecyl allyl ammonium bromide (BC 16 ) preparation:

[0038] A three-necked flask equipped with a thermometer and a reflux condenser was placed in a water bath controlled by a magnetic stirrer, and 40 mL of anhydrous tetrahydrofuran, 12.92 g (0.15 mol) of N,N-dimethylpropenylamine, 50.38 g (0.165 mol) of N-dimethylpropenylamine were added. 1-Bromohexadecane and 0.49g (0.0075mol) zinc powder were reacted at 65°C for 10h, and the reaction was completed. The tetrahydrofuran was rotary evaporated at 45°C, washed with 30 mL of anhydrous ether for 5 times, and vacuum-dried at 45°C for 5 h to obtain the product.

[0039] The second step: Dimethylhexadecyltriisopropylsilylpropylammonium bromide (TPBC 16 ) preparation:

[0040] Add dimethylhexadecylallylammonium bromide (0.01mol) and 2 mL of chloroplatinic acid catalyst into a three-necked flask equipped wit...

Embodiment 3

[0041]Embodiment 3: prepare organosilicon quaternary ammonium salt surfactant as follows:

[0042] The first step: Dimethyl octadecyl allyl ammonium bromide (BC 18 ) preparation:

[0043] A three-necked flask equipped with a thermometer and a reflux condenser was placed in a water bath controlled by a magnetic stirrer, and 40 mL of anhydrous tetrahydrofuran, 8.62 g (0.1 mol) of N,N-dimethylpropenylamine, 24.92 g (0.11 mol) of N-dimethylpropenylamine were added. 1-Bromooctadecane and 0.33g (0.005mol) zinc powder were reacted at 50°C for 18h, and the reaction was completed. At 45°C, tetrahydrofuran was rotary evaporated, washed with 30 mL of anhydrous ether for 5 times, and vacuum-dried at 45°C for 5 hours to obtain the product.

[0044] The second step: dimethyl octadecyl trihexyl propyl ammonium bromide (TPBC 18 ) preparation:

[0045] Add dimethyl octadecyl allyl ammonium bromide (0.01 mol) and 6 mL of chloroplatinic acid catalyst into a three-necked flask equipped with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com