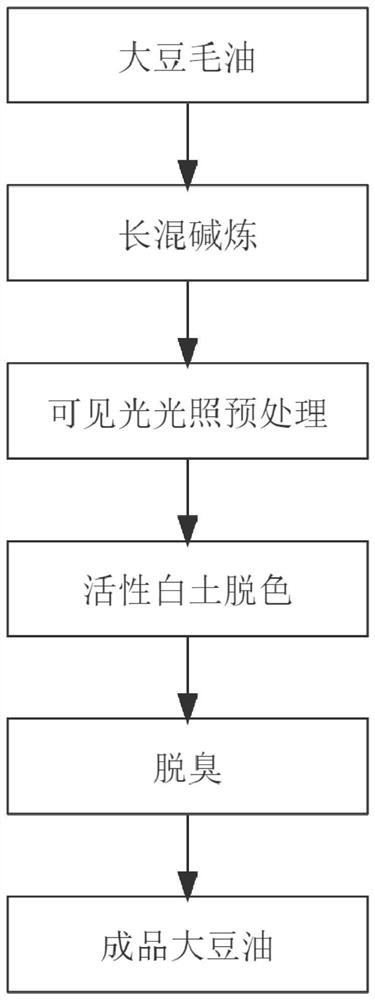

Processing method of soybean oil

A processing method, soybean oil technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems of high loss of neutral oil, large amount of decolorizing agent, high cost, etc., to reduce the loss of neutral oil, reduce the amount of white clay, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Step 1. Preparation of crude soybean oil: crude soybean oil is prepared by extrusion puffing and leaching. The main indicators of the obtained crude soybean oil are as follows: it has the proper smell and taste of crude soybean oil, has no peculiar smell, and contains impurities <0.2% , solvent residue <100mg / kg, acid value ≤4mg / g, peroxide value ≤0.25g / 100g; the triglyceride content in crude oil is about 94.4%, the phospholipid content is about 3.7%, and the unsaponifiable matter content is 1.3% ~1.6%, free fatty acid content is 0.3~0.7%, and hydrocarbon content is about 0.38%.

[0030] In step 2, the crude soybean oil obtained in step 1 is subjected to a long mixing alkali refining process. 85% phosphoric acid, the amount of addition is 0.05-0.15% of the oil weight, and the reaction is 15-30 minutes after being homogenized and mixed by a mixer; The lye solution with a concentration of 2-3%, the controlled addition amount is 1-3% of the oil weight, and the reaction is...

Embodiment 1

[0035] step one

[0036] That is, the preparation of soybean crude oil is obtained by extrusion puffing and leaching. The obtained crude oil should have the proper smell and taste of soybean crude oil, no peculiar smell, impurity content <0.2%, solvent residue <100mg / kg, acid value≤4mg / g, peroxide value≤0.25g / 100g. The triglyceride content in the crude oil is about 94.4%, the phospholipid content is about 3.7%, the unsaponifiable matter content is 1.3-1.6%, the free fatty acid content is 0.3-0.7%, and the hydrocarbon content is about 0.38%.

[0037] Step 2

[0038] The obtained crude soybean oil was heated to 70°C in a storage tank, phosphoric acid with a concentration of 85% was added, and the addition amount was 0.10% of the oil weight, and the reaction was held for 15 minutes after being homogenized and mixed by a mixer; The heat exchanger cools the oil temperature to 40°C, then adds lye solution with a concentration of 2%, and controls the addition amount to be 1.5% by ...

Embodiment 2

[0046] step one

[0047] That is, the preparation of soybean crude oil is obtained by extrusion puffing and leaching. The obtained crude oil should have the proper smell and taste of soybean crude oil, no peculiar smell, impurity content <0.2%, solvent residue <100mg / kg, acid value≤4mg / g, peroxide value≤0.25g / 100g. The triglyceride content in the crude oil is about 94.4%, the phospholipid content is about 3.7%, the unsaponifiable matter content is 1.3-1.6%, the free fatty acid content is 0.3-0.7%, and the hydrocarbon content is about 0.38%.

[0048] Step 2

[0049] The obtained crude soybean oil was heated to 70°C in a storage tank, phosphoric acid with a concentration of 85% was added, and the addition amount was 0.10% of the oil weight, and the reaction was held for 15 minutes after being homogenized and mixed by a mixer; The heat exchanger cools the oil temperature to 40°C, then adds lye solution with a concentration of 2%, and controls the addition amount to be 1.5% by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com