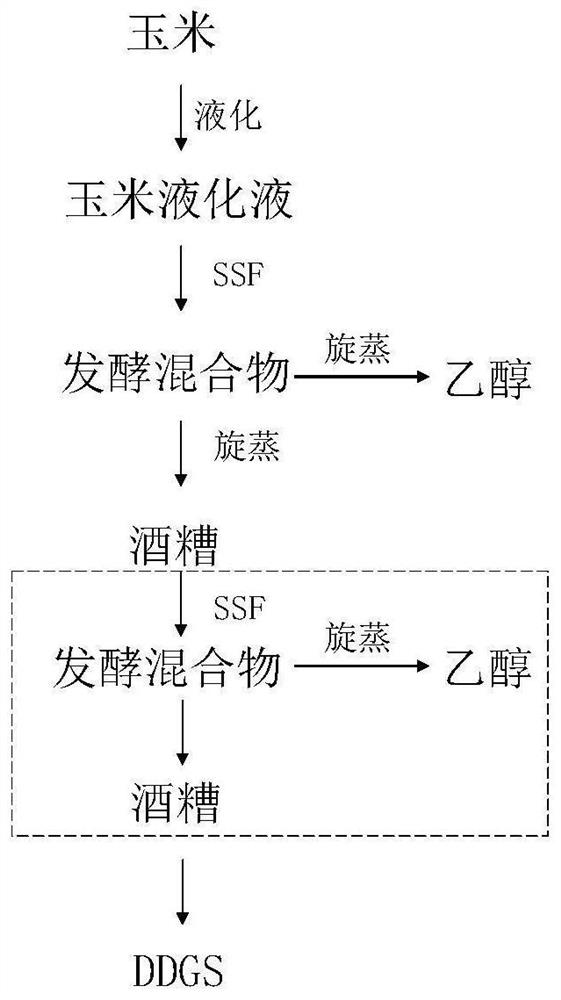

Method for improving quality of DDGS (distillers dried grains with soluble) in corn ethanol process through secondary fermentation of distillers' grains

A secondary fermentation and ethanol technology, applied in the direction of fermentation, etc., can solve the problems affecting the effective content of lysine, the dark brown color of DDGS, and the quality of DDGS, so as to inhibit Maillard reaction, weaken Maillard reaction, high Effect of Corn Starch Conversion and Ethanol Yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

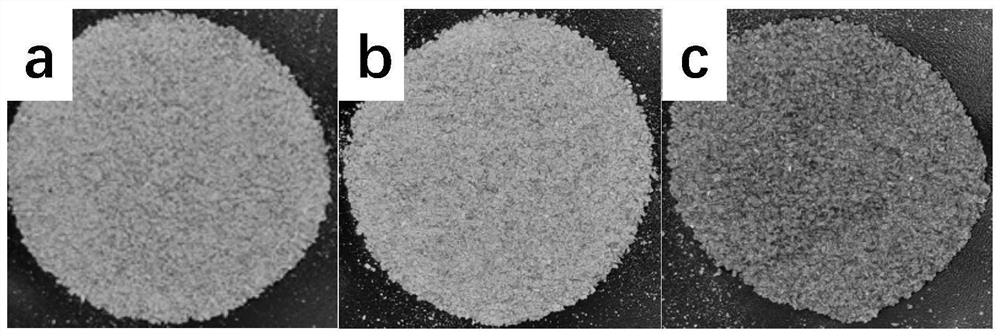

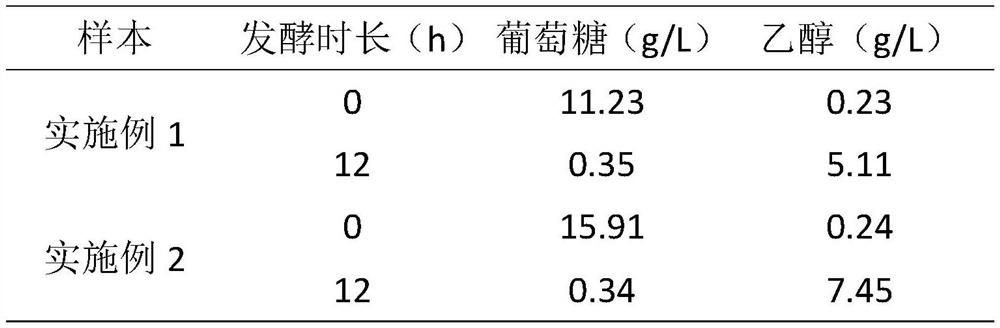

Embodiment 1

[0052] The DDGS of this example was prepared by the following method:

[0053] (1) the corn flour is mixed with water, so that the dry weight of the corn flour in the mixed solution is 30wt%, and stirring is uniform;

[0054] (2) adjusting the pH of the above-mentioned corn suspension to 5.8, adding starch liquefaction enzyme, the amount of starch liquefaction enzyme added is 0.048wt% of the dry weight of corn flour, and liquefying at 90°C for 3 hours to obtain corn liquefaction liquid;

[0055] (3) cooling the above-mentioned corn liquefaction liquid to 30° C., adjusting the pH to 5.0, adding starch saccharification enzyme, cellulase and hemicellulase, wherein the addition amount of saccharification enzyme is 0.1 wt % of the dry weight of corn flour, and cellulase The addition amount is 0.6wt% of the dry weight of corn flour, the addition amount of hemicellulase is 0.1wt% of the dry weight of corn flour, urea is added, and the addition amount of urea is 1.28g / kg slurry, and t...

Embodiment 2

[0061] The DDGS of this example was prepared by the following method:

[0062] (1) the corn flour is mixed with water, so that the dry weight of the corn flour in the mixed solution is 30wt%, and stirring is uniform;

[0063] (2) adjusting the pH of the above-mentioned corn suspension to 5.8, adding starch liquefaction enzyme, the amount of starch liquefaction enzyme added is 0.048wt% of the dry weight of corn flour, and liquefying at 90°C for 3 hours to obtain corn liquefaction liquid;

[0064] (3) cooling the above-mentioned corn liquefaction liquid to 30° C., adjusting the pH to 5.0, adding starch saccharification enzyme, cellulase and hemicellulase, wherein the addition amount of saccharification enzyme is 0.1 wt % of the dry weight of corn flour, and cellulase The addition amount is 0.6wt% of the dry weight of corn flour, the addition amount of hemicellulase is 0.1wt% of the dry weight of corn flour, urea is added, and the addition amount of urea is 1.28g / kg slurry, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com