Method for extracting ceramide from malus micromalus rice bran

A technology of ceramide and rice bran, which is applied in the field of enzymatic hydrolysis, can solve the problems of insufficient extraction of ceramide and low yield, and achieve the effects of high extraction rate and purity, convenient extraction and short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

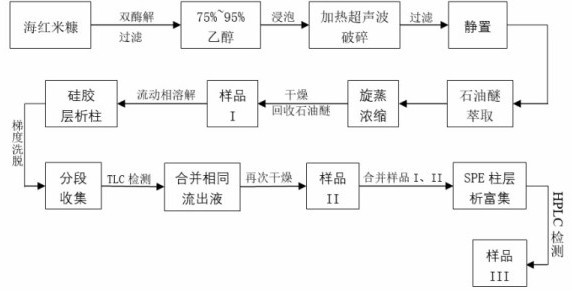

Method used

Image

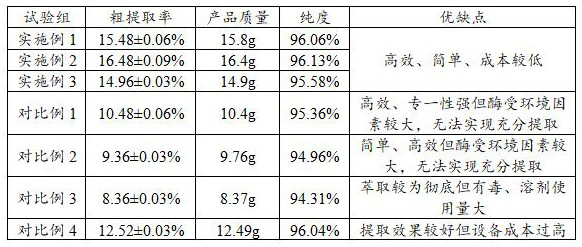

Examples

Embodiment 1

[0023] This example provides an application test of extracting ceramides from sea red rice bran by using double-enzymatic enzymolysis combined with ultrasonic thermal extraction technology.

[0024] Remove impurities from the dried sea red rice bran material, pulverize and sieve to obtain 20-40 mesh rice bran raw material powder, take 100 g of sea red rice bran, add 300 mL (calculated in enzyme activity units, sphingomyelinase and cellulase) The ratio is 4:6) in the enzymatic hydrolysis solution (concentration of 0.2w / v%) of the preparation, at 35 ° C, the pH is adjusted to 5, the enzymatic hydrolysis is carried out for 60 minutes, and the filtration is performed to obtain the enzymatic hydrolysis of rice bran (water). Take 1 g of enzymatically hydrolyzed rice bran (water), add 500 mL of 75% ethanol solution, stir for 20 minutes, let it stand and soak for 1 hour, then seal it and put it into an ultrasonic cleaner, start the program, select the ultrasonic power as 360w, and the ...

Embodiment 2

[0030] This example provides an application test of extracting ceramides from sea red rice bran by using double-enzymatic enzymolysis combined with ultrasonic thermal extraction technology.

[0031] The extraction process in this example is the same as that in Example 1, except that the concentration of the enzymatic hydrolysis solution is 0.4w / v%, the temperature of the enzymatic hydrolysis is 40°C, the pH of the enzymatic hydrolysis is 6, and the enzymatic hydrolysis time is 90 min; 400 mesh silica gel, the ratio of the loading amount of the ceramide extract to the silica gel is 3:100, and the elution speed of petroleum ether and ethyl acetate is 3BV / h; in the SPE small column, the working pressure is 5bar .

Embodiment 3

[0033] This example provides an application test of extracting ceramides from sea red rice bran by using double-enzymatic enzymolysis combined with ultrasonic thermal extraction technology.

[0034] The extraction process in this example is the same as that in Example 1, except that the concentration of the enzymatic hydrolysis solution is 0.5w / v%, the temperature of the enzymatic hydrolysis is 45°C, the pH of the enzymatic hydrolysis is 7, the enzymatic hydrolysis time is 120 min, and the concentration of the ethanol solution is 95 %; the ratio of the loading amount of the ceramide extract and the silica gel is 5:100, and the elution speed of the petroleum ether and ethyl acetate is 4BV / h; the consumption of the ethyl acetate and acetone is 2.5BV, The elution rate was 1.5 BV / h and the working pressure was 20 bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com