Low-bitterness rice peptide with anti-oxidation and anti-fatigue effects and preparation method of low-bitterness rice peptide

An anti-oxidation and anti-fatigue technology, applied in the field of food deep processing, can solve the problems of limited popularization and application, unfavorable large-scale industrial production, strong bitter taste, etc., and achieves the effect of prolonging the shelf life, considerable yield and reducing bitter taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

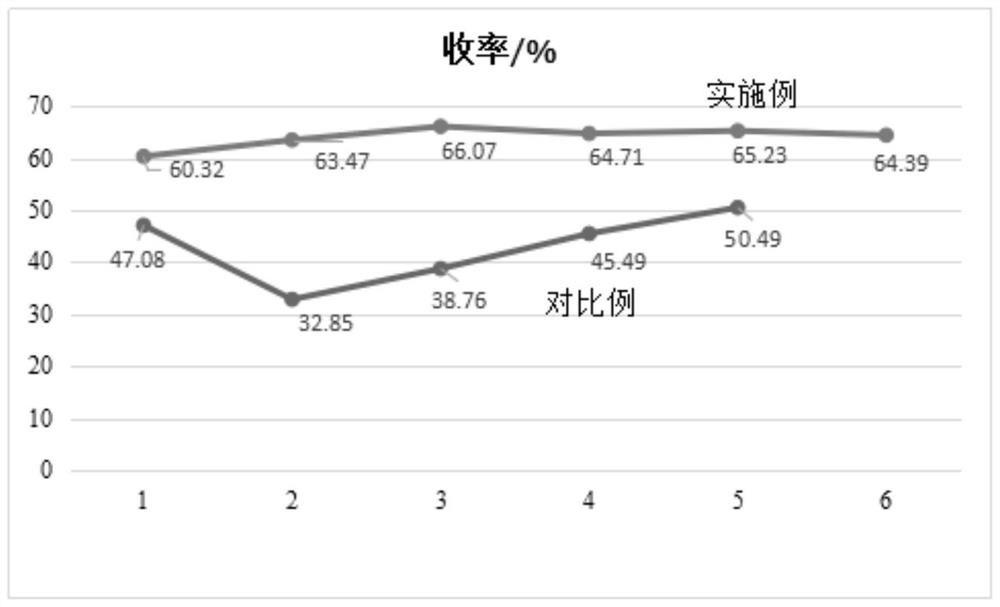

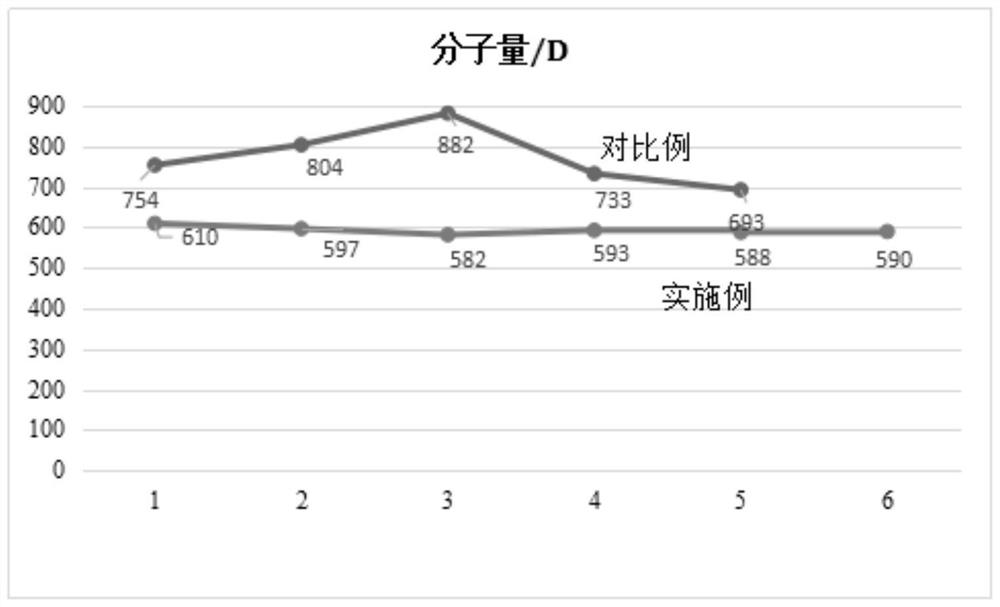

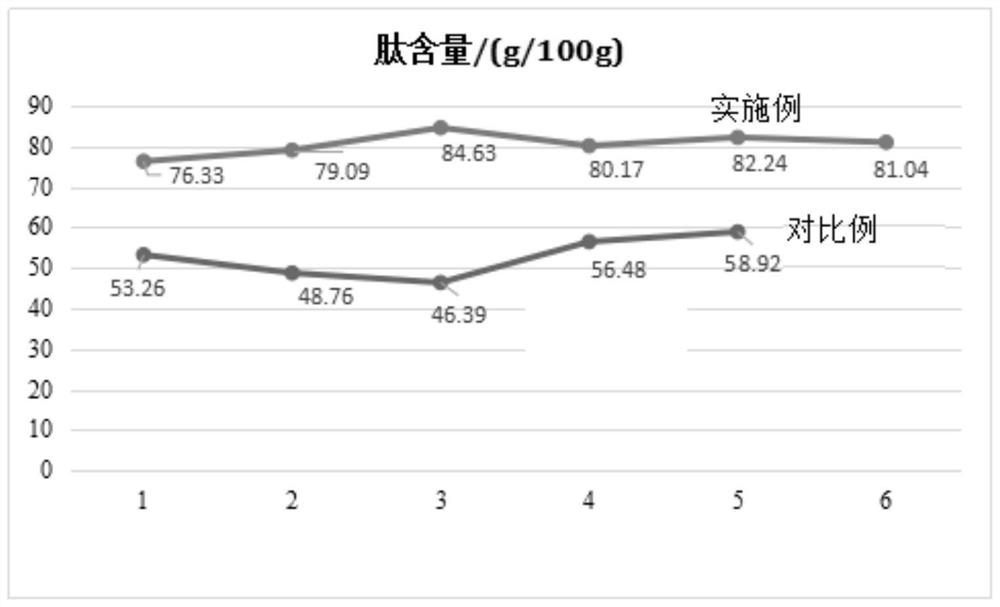

Examples

Embodiment 1

[0035] A preparation method of a rice peptide with low bitterness and anti-oxidative and anti-fatigue effect, the steps are as follows:

[0036] (1) Pretreatment: the rice protein powder is colloid milled with 8 times of deionized water;

[0037] (2) Denaturation: denaturation at 80°C for 2 hours;

[0038] (3) One-time enzymatic hydrolysis: adjust the pH to 8.5-9.0 with food-grade sodium hydroxide, raise the temperature to 60 °C, add Bacillus subtilis alkaline protease with a feed content of 5wt‰, maintain the pH to 8.0-9.0 during the process, and enzymatic hydrolysis The time is 2h, and after the end, the temperature is raised to 90°C to inactivate the enzyme for 15min;

[0039] (4) Secondary enzymatic hydrolysis: adjust the pH to 6.0-7.0 with food-grade hydrochloric acid, heat up to 45-50 °C, add papain with a feeding amount of 5wt‰, the pH is not maintained during the process, and the enzymatic hydrolysis time is 3h. The temperature was raised to 90°C to inactivate the en...

Embodiment 2

[0045] A preparation method of a rice peptide with low bitterness and anti-oxidative and anti-fatigue effect, the steps are as follows:

[0046] (1) Pretreatment: the rice protein powder is colloid milled with 10 times of deionized water;

[0047] (2) Denaturation: denaturation at 90°C for 1.5h;

[0048] (3) One enzymatic hydrolysis: adjust the pH to 6.5-7.5 with food-grade sodium hydroxide, raise the temperature to 55 °C, and add neutral protease of Bacillus subtilis with a feeding amount of 2 wt%. The pH is not maintained during the process, and the enzymatic hydrolysis time is 4 h. After the end, the temperature was raised to 90°C to inactivate the enzyme for 15min;

[0049] (4) Secondary enzymatic hydrolysis: adjust the pH to 7.5-8.0 with food-grade sodium hydroxide, raise the temperature to 50-60 °C, add flavor protease with a feeding amount of 3wt‰, do not maintain pH during the process, and the enzymatic hydrolysis time is 3h, After the end, the temperature was raised...

Embodiment 3

[0055] A preparation method of a rice peptide with low bitterness and anti-oxidative and anti-fatigue effect, the steps are as follows:

[0056] (1) Pretreatment: the rice protein powder is colloid milled with 12 times of deionized water;

[0057](2) Denaturation: denaturation at 100°C for 1 hour;

[0058] (3) One-time enzymatic hydrolysis: adjust the pH to 6.0-7.0 with food-grade sodium hydroxide, raise the temperature to 55 °C, add trypsin with a content of 1 wt% in the feeding amount, keep the pH unchanged during the process, and the enzymatic hydrolysis time is 6 h. The temperature was raised to 95°C to inactivate the enzyme for 15min;

[0059] (4) Secondary enzymatic hydrolysis: adjust the pH to 7.0-7.5 with food-grade sodium hydroxide, raise the temperature to 50 °C, add papain with a feed content of 1wt‰ and flavor protease with a content of 1wt‰, without maintaining pH during the process, enzymatic hydrolysis The time was 2h, and after the end, the temperature was ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com