Nitrogen-doped carbon-based Co/Ni12P5 oxygen evolution catalyst as well as preparation method and application thereof

A nitrogen-doped carbon and catalyst technology, applied in the direction of electrolysis components, electrodes, electrolysis process, etc., can solve the problems of high cost, low repeatability, unfavorable large-scale commercial application, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

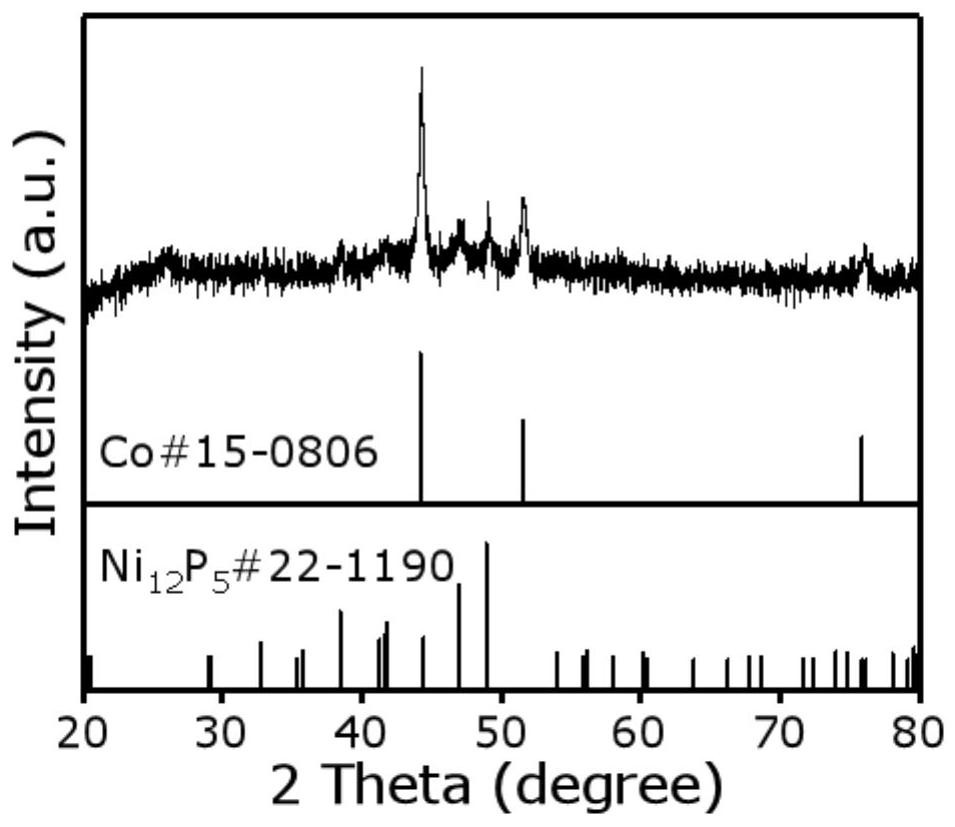

[0020] The invention provides a nitrogen-doped carbon-based Co / Ni 12 P 5 The preparation method of oxygen evolution catalyst comprises the following steps:

[0021] The cobalt source, nickel source, triphenylphosphine and melamine are mixed and sintered to obtain nitrogen-doped carbon-based Co / Ni 12 P 5 Oxygen evolution catalyst.

[0022] In the present invention, unless otherwise specified, the required preparation raw materials are all commercially available products well known to those skilled in the art.

[0023] In the present invention, the cobalt source is preferably cobalt nitrate; the nickel source is preferably nickel nitrate. The present invention utilizes triphenylphosphine to provide P element, and utilizes melamine to provide N and C elements.

[0024] In the present invention, the mass ratio of the cobalt source, nickel source, triphenylphosphine and melamine is preferably (0.25-0.5):(0.25-0.5):(0.25-0.5):(1-1.5).

[0025] In the present invention, the cob...

Embodiment 1

[0033] Put 0.25g of cobalt nitrate, 0.25g of nickel nitrate, 1.5g of melamine and 0.5g of triphenylphosphine in the grinding body, grind it into powder, place it in a porcelain boat, put the porcelain boat into a tube furnace, The temperature was raised to 900 °C for 1 h and sintered in an argon atmosphere to obtain nitrogen-doped carbon-based Co / Ni. 12 P 5 Oxygen evolution catalyst, denoted as 1-Co / Ni 12 P 5 @N-C.

Embodiment 2

[0035] Put 0.25g of cobalt nitrate, 0.5g of nickel nitrate, 1.5g of melamine and 0.5g of triphenylphosphine in the grinding body, grind it into powder, put it in a porcelain boat, put the porcelain boat into a tube furnace, The temperature was raised to 900 °C for 1 h and sintered in an argon atmosphere to obtain nitrogen-doped carbon-based Co / Ni. 12 P 5 Oxygen evolution catalyst, denoted as 2-Co / Ni 12 P 5 @N-C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com