NiCoSe/carbon cloth/S composite lithium-sulfur battery positive electrode material and preparation method thereof

A technology of positive electrode materials and composite materials, which is applied in the field of preparation of electrode materials for lithium-sulfur batteries, can solve the problems of reducing the stability of electrode materials, poor adsorption of polysulfides, damage performance and structure, etc., to suppress the shuttle effect and improve the electrochemical performance. Performance, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

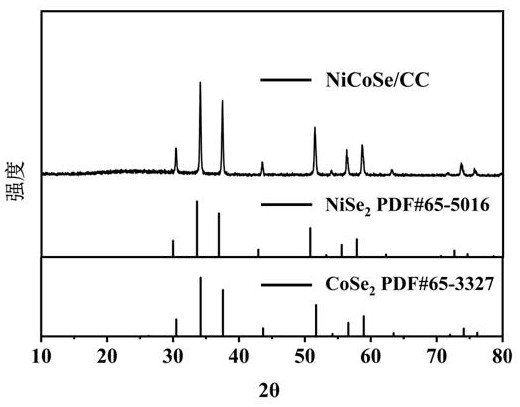

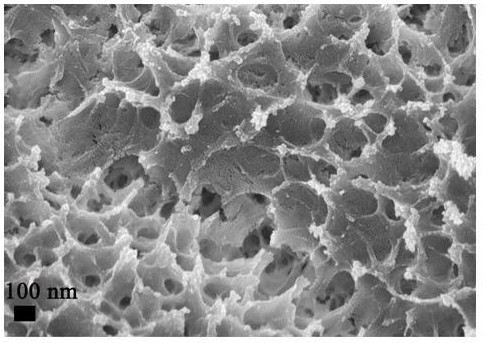

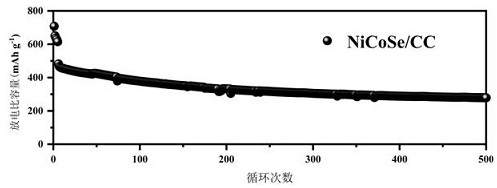

[0032] A NiCoSe / carbon cloth / S composite lithium-sulfur battery cathode material, prepared by the following method:

[0033] Prepare a piece of cut carbon cloth with acetone, ethanol, and deionized water for 15 min respectively, put it in an oven to dry at 80 °C, and then calcine it at 900 °C for 2 h in an argon atmosphere; take 0.3 g cobalt nitrate hexahydrate and 0.3 g cobalt nitrate hexahydrate and 0.3 g Nickel nitrate hexahydrate was added to 20 ml methanol solution, stirred for 10-20 min to prepare solution A; 3.28 g of 2-methylimidazole was added to 20 ml methanol solution, stirred and dissolved to prepare solution B; solution B was added into solution A, stirred for 20-30min, and then transferred to the reaction kettle together with the pretreated carbon cloth at 120°C, and reacted for 14 h; the heat-treated carbon cloth was rinsed with ethanol for 2-4 times, and the The cleaned carbon cloth was placed in an oven to dry at 80 °C; the dried carbon cloth and 0.5 g of sele...

Embodiment 2

[0036] A NiCoSe / carbon cloth / S composite lithium-sulfur battery cathode material, prepared by the following method:

[0037] Prepare a cut carbon cloth with acetone, ethanol, and deionized water for 10 min respectively, put it in an oven to dry at 80 °C, and then calcine it at 900 °C for 3 h in an argon atmosphere; take 0.6 g of cobalt nitrate hexahydrate and 0.3 g of cobalt nitrate hexahydrate. Nickel nitrate hexahydrate was added to 35 ml methanol solution, stirred for 10-20 min, to prepare solution A; 4.92 g of 2-methylimidazole was added to 35 ml methanol solution, stirred and dissolved to prepare solution B; solution B was added into solution A, stirred for 20-30min, and then transferred to the reaction kettle together with the pretreated carbon cloth at 120°C, and reacted for 16 h; the heat-treated carbon cloth was rinsed with ethanol for 2-4 times, and the The cleaned carbon cloth was placed in an oven to dry at 80 °C; the dried carbon cloth and 0.5 g of selenium powder...

Embodiment 3

[0040] A NiCoSe / carbon cloth / S composite lithium-sulfur battery cathode material, prepared by the following method:

[0041] Prepare a cut carbon cloth with acetone, ethanol, and deionized water for 10 min respectively, put it in an oven to dry at 80 °C, and then calcine it at 900 °C for 3 h in an argon atmosphere; take 0.6 g of cobalt nitrate hexahydrate and 0.6 g of cobalt nitrate hexahydrate. Nickel nitrate hexahydrate was added to 35 ml methanol solution, stirred for 10-20 min to prepare solution A; 6.56 g of 2-methylimidazole was added to 35 ml methanol solution, stirred and dissolved to prepare solution B; solution B was added into solution A, stirred for 20-30min, and then transferred to the reaction kettle together with the pretreated carbon cloth at 120°C, and reacted for 16 h; the heat-treated carbon cloth was rinsed with ethanol for 2-4 times, and the The cleaned carbon cloth was placed in an oven to dry at 80 °C; the dried carbon cloth and 0.5 g selenium powder wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com