Drug balloon catheter as well as preparation method and application thereof

A balloon catheter and drug technology, applied in balloon catheters, catheters, coatings and other directions, can solve the problems of reducing the firmness of drug coatings, loosening and loss of drug coatings, etc., so as to improve drug utilization and reduce drug Loss, the effect of increasing the release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

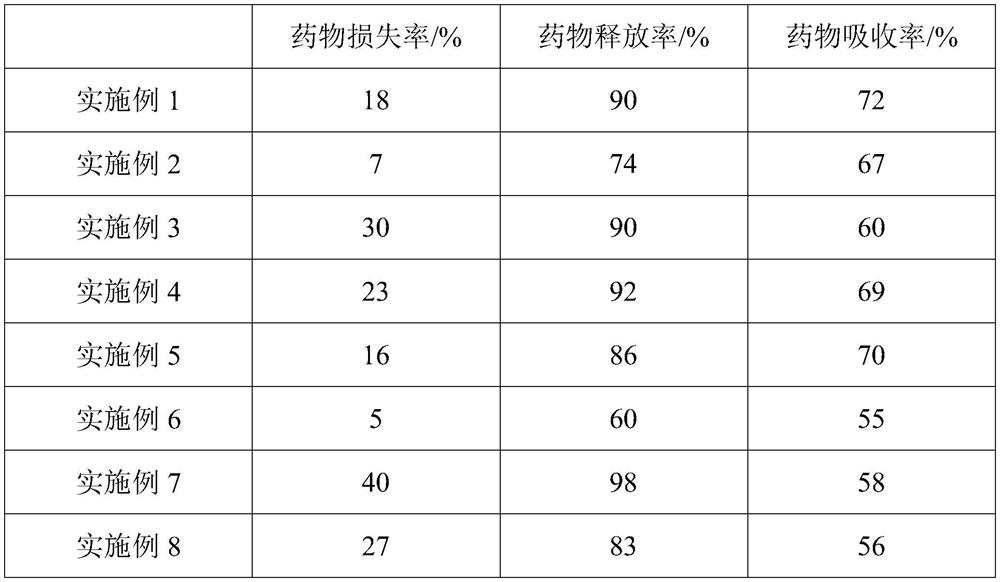

Embodiment 1

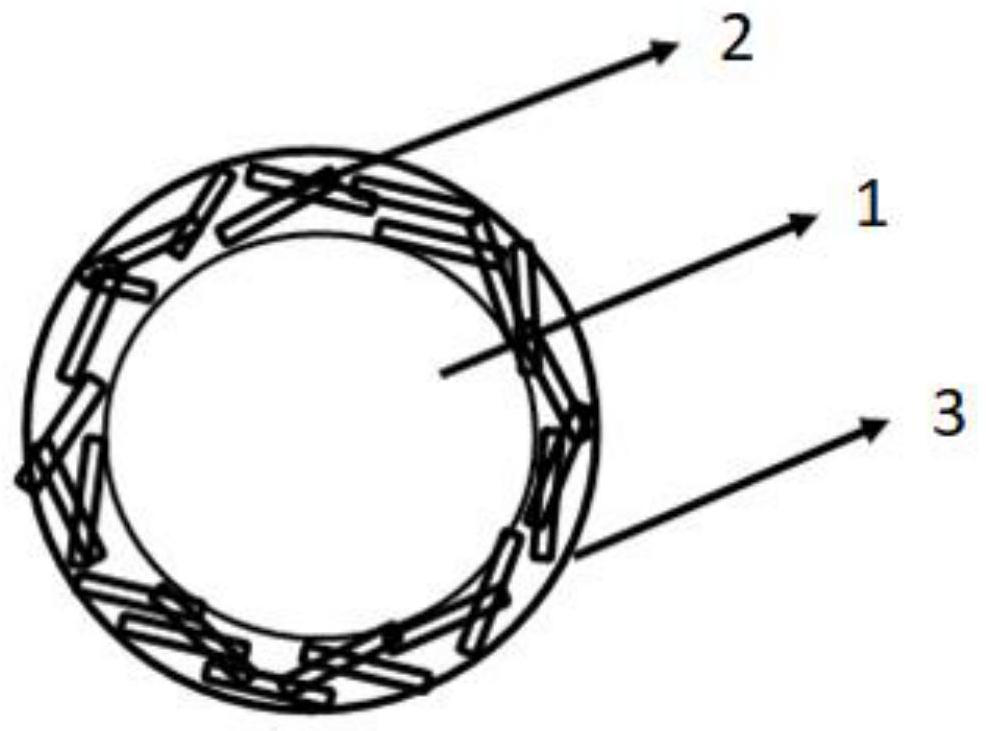

[0083] This embodiment provides a preparation method of a drug balloon catheter, and the preparation method includes:

[0084] (1) After the balloon catheter 1 is inflated, under ultrasonic conditions, rapamycin and dibutylhydroxytoluene are dissolved in isopropanol to obtain a drug coating solution, wherein the rapamycin in the drug coating solution is The concentration of pyruvate was 25 mg / mL, and the concentration of dibutyl hydroxytoluene was 1.5 mg / mL;

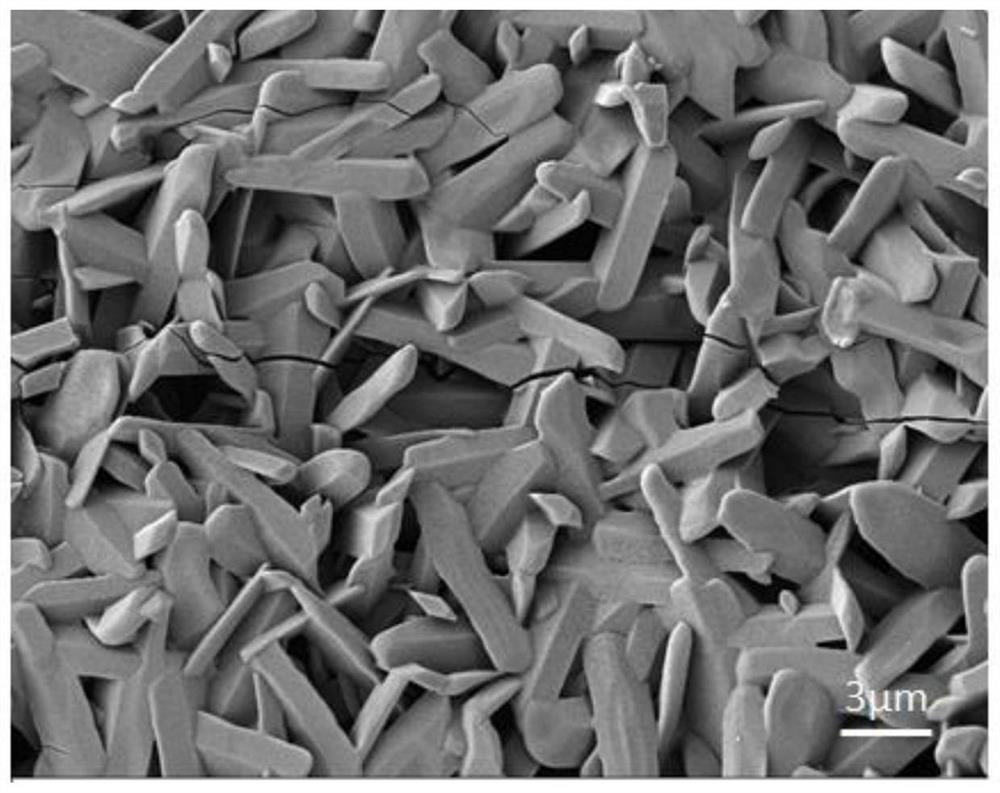

[0085] (2) the drug coating solution obtained in step (1) is applied to the outer surface of the balloon catheter 1 by the method of ultrasonic atomization spraying, and then repeated spraying is carried out after drying, wherein, the process parameters of ultrasonic atomization spraying include: The atomization power is 0.9W, the drainage air flow is 1.0psi, the spraying temperature is 24°C, the spraying humidity is 45%, the spraying flow rate is 0.05mL / min, and the feeding speed of the balloon catheter 1 is 3cm / s , th...

Embodiment 2

[0090] This embodiment provides a preparation method of a drug balloon catheter, and the preparation method includes:

[0091] (1) After the balloon catheter 1 is inflated, under ultrasonic conditions, rapamycin and dibutylhydroxytoluene are dissolved in isopropanol to obtain a drug coating solution, wherein the rapamycin in the drug coating solution is The concentration of pyruvate was 50 mg / mL, and the concentration of dibutyl hydroxytoluene was 5 mg / mL;

[0092] (2) the drug coating solution obtained in step (1) is coated on the outer surface of the balloon catheter 1 by the method of ultrasonic atomization spraying, and then repeated spraying is carried out after drying, wherein, the process parameters of ultrasonic atomization spraying include: The atomization power is 0.8W, the drainage air flow is 0.6psi, the spraying temperature is 30°C, the spraying humidity is 50%, the spraying flow rate is 0.01mL / min, and the feeding speed of the balloon catheter 1 is 0.1cm / s, the...

Embodiment 3

[0097] This embodiment provides a preparation method of a drug balloon catheter, and the preparation method includes:

[0098] (1) After the balloon catheter 1 is inflated, under ultrasonic conditions, rapamycin and dibutylhydroxytoluene are dissolved in isopropanol to obtain a drug coating solution, wherein the rapamycin in the drug coating solution is The concentration of pyruvate was 5 mg / mL, and the concentration of dibutyl hydroxytoluene was 0.05 mg / mL;

[0099] (2) the drug coating solution obtained in step (1) is applied to the outer surface of the balloon catheter 1 by the method of ultrasonic atomization spraying, and then repeated spraying is carried out after drying, wherein, the process parameters of ultrasonic atomization spraying include: The atomization power is 1.2W, the drainage air flow is 1.2psi, the spraying temperature is 20°C, the spraying humidity is 30%, the spraying flow rate is 1mL / min, the feeding speed of the balloon catheter 1 is 5cm / s, The rotati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com