Liquid-liquid split-phase type carbon dioxide absorption and desorption system

A carbon dioxide and liquid separation technology, applied in chemical instruments and methods, using liquid separation agents, separation methods, etc., can solve problems such as increased viscosity of rich phases, increased process energy consumption, and insufficient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

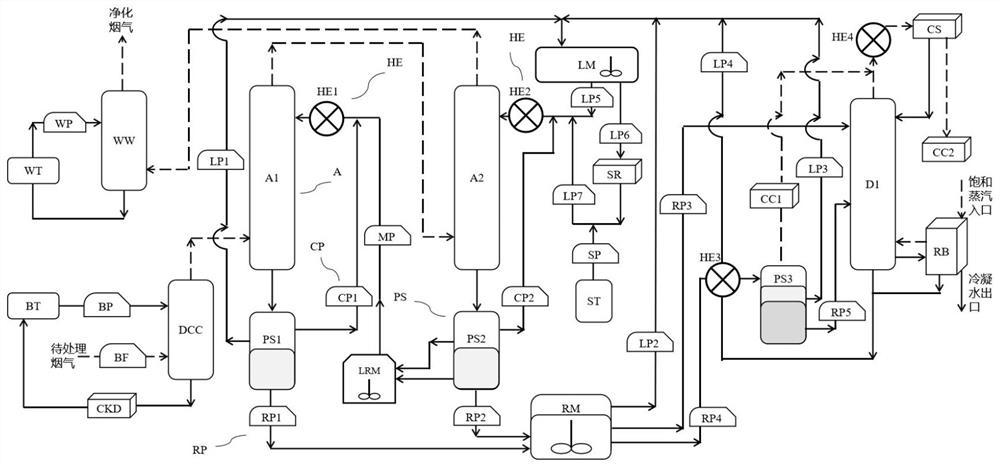

[0024] like figure 1 As shown, a liquid-liquid split-phase carbon dioxide absorption and desorption system, its main structure includes: absorption tower A, desorption tower D1, several liquid-liquid separation pools PS, two-phase mixing pool LRM, rich-phase mixing pool RM , Lean liquid mixing pool LM, several heat exchange devices HE, gas compressor CC1, carbon dioxide compressor CC2, gas-liquid separator CS and several liquid pumps.

[0025] There are several absorption towers A, which are connected in series with each other. In this embodiment, two absorption towers A are set, ie, a first-stage absorption tower A1 and a second-stage absorption tower A2. This is an example to illustrate. In practical application, the two-stage towers can also be integrated into a larger tower. The external carbon dioxide-containing flue gas to be treated is communicated with the flue gas inlet at the lower part of the primary absorption tower A1 through the pipeline, and the flue gas outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com