Automobile lightweight aluminum alloy hot die forging press

A hot die forging press, lightweight technology, applied in the driving device of forging press, forging/pressing/hammering machinery, forging/pressing/hammer device, etc. Long and other problems, to achieve the effect of improving strength, saving space and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

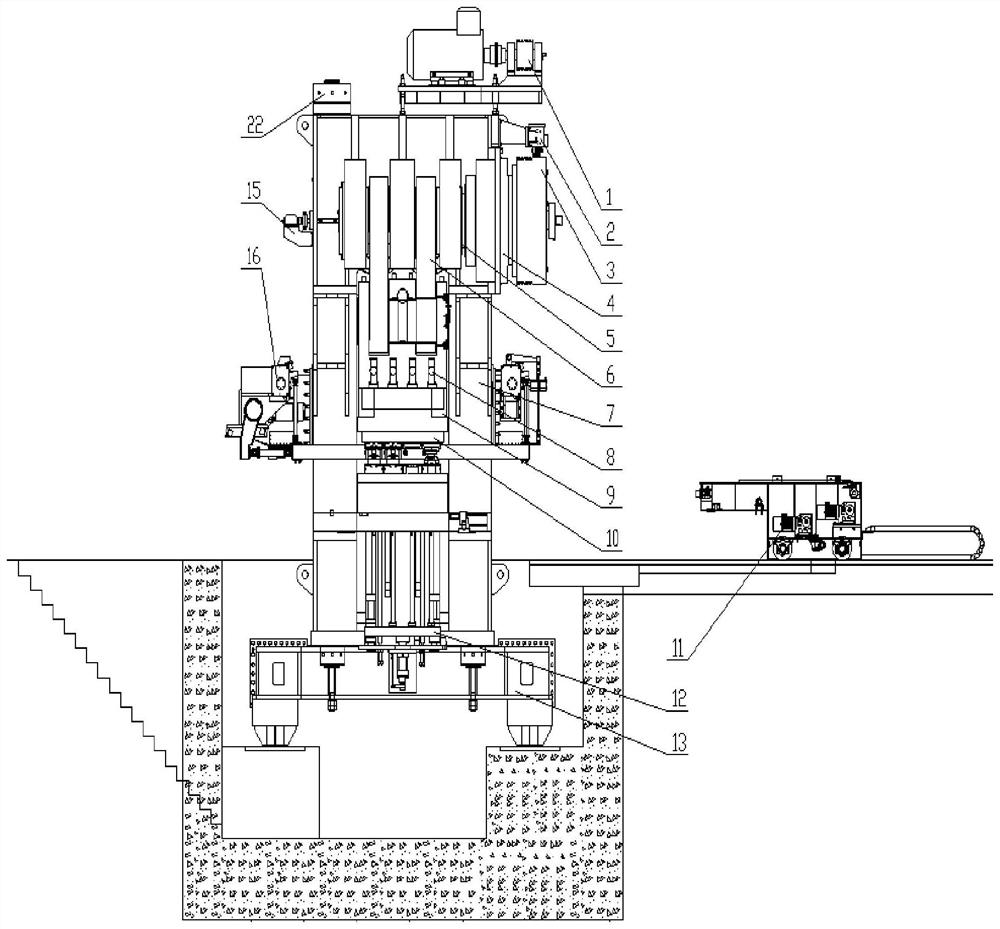

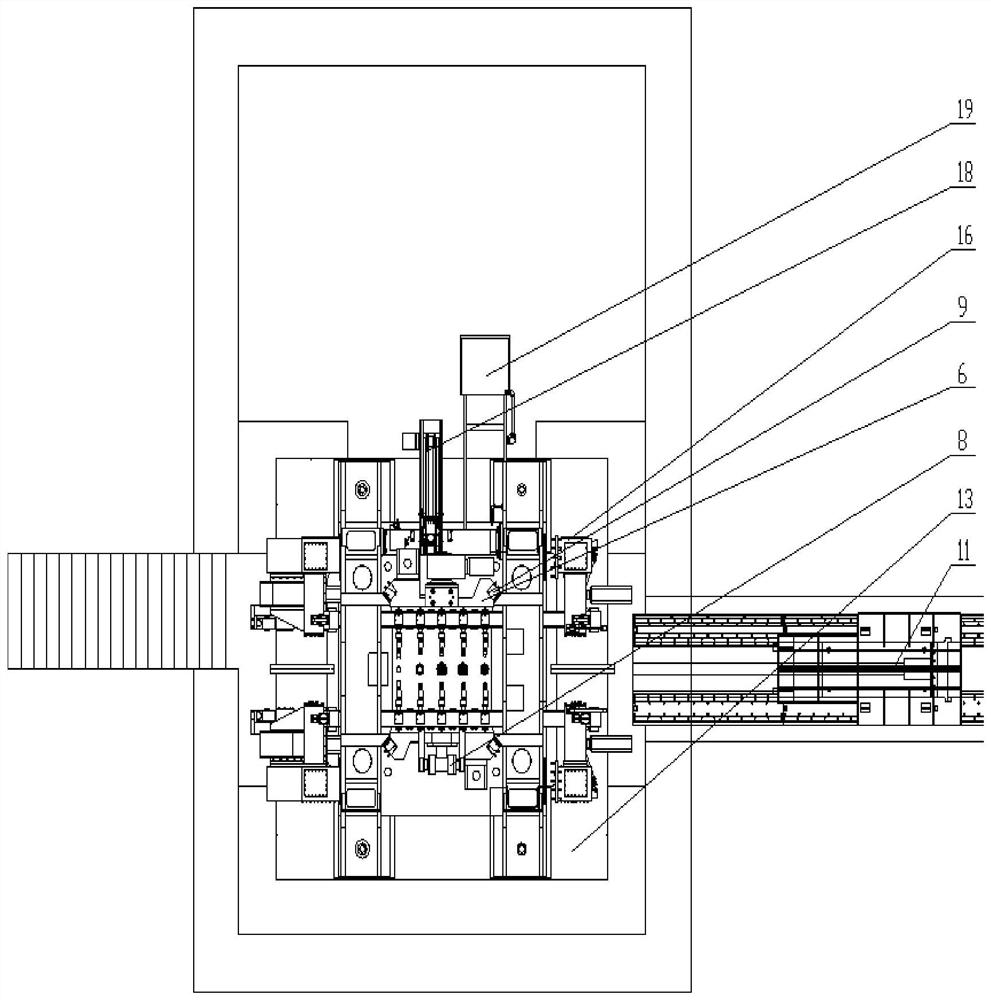

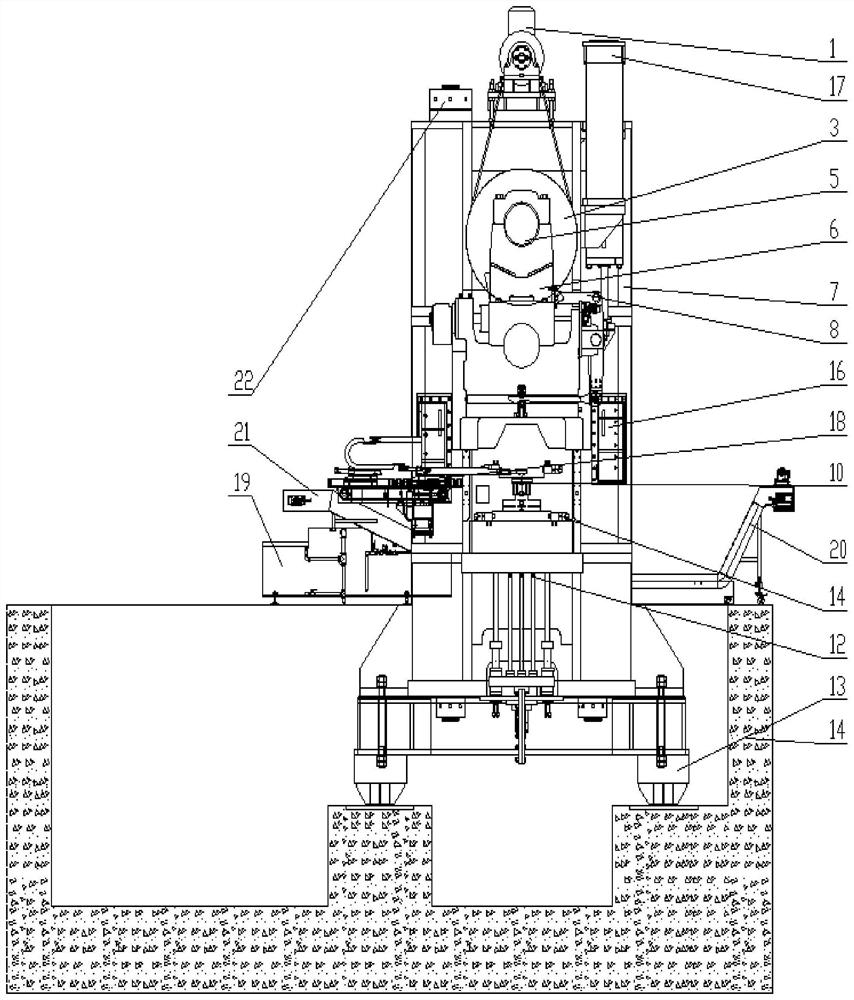

[0098] The present invention will be further described below with reference to the accompanying drawings. like Figure 1-13 As shown, an automobile lightweight aluminum alloy hot die forging press includes a body 7, a flywheel brake 2, a main drive system 3, a planetary gear reducer 4, a crankshaft mechanism 5, a slider and a connecting rod mechanism 6, an upper Feeding mechanism 8, guide device 9, mold and mold base mechanism 10, articulated mold changing device 11, lower ejector mechanism 12, elastic foundation 13, intelligent mold clamp 14, cam control device 15, servo-type flexible walking beam Mechanism 16, balancer mechanism 17, spraying manipulator 18 and hydraulic control system 22 of hot die forging unwinding car;

[0099] The fuselage 7 is a vertical beam-column structure, including a beam, a column and a base 1009. There are two columns. The bottoms of the two columns are fixed on the base 1009 by tightening bolts, and the upper parts of the two columns are respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com