Self-cleaning antibacterial coating and preparation method thereof

An antibacterial coating and self-cleaning technology, applied in the field of coatings, can solve problems such as poor self-cleaning performance, achieve the effects of improving antibacterial stability and durability, improving antibacterial durability, and improving adhesion and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

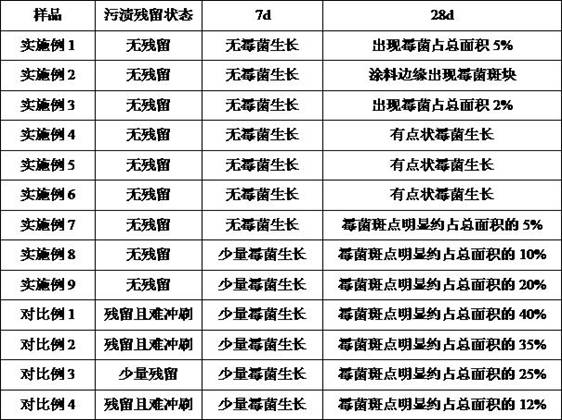

Examples

preparation example 1

[0048] A porous silica particle:

[0049] 0.5kg hexadecyl trimethoxy ammonium bromide, 80kg mass fraction 8% ethanol solution, 12kg cyclohexane and 0.5kg1mol / L ammoniacal liquor are stirred and mixed, and the mixed solution is collected;

[0050] 0.1kg of aminopropyltrimethoxysilane and 1kg of absolute ethanol were added to 3kg of ethyl orthosilicate, stirred and mixed, and the reaction solution was collected;

[0051] The reaction was added dropwise to the mixed solution, kept stirring at 55°C for the reaction, the filter cake was collected by filtration, washed and then vacuum-dried at 45°C to prepare porous silica particles 1 with an average pore size of 5.25-10.85 μm.

preparation example 2

[0053] Compared with preparation example 1, in this preparation example 2, the same quality of sodium lauryl sulfate was used instead of cetyltrimethoxyammonium bromide in preparation example 1 to prepare porous dioxide with an average pore size of 0.32-0.85 μm. Silicon particles 2.

preparation example 3

[0055] Titanium dioxide sol solution: take 0.1kg of tetrabutyl titanate and stir and mix with 1kg of absolute ethanol, and collect the composite solution;

[0056] Then get 0.6kg water, 1kg dehydrated alcohol, 0.2kg acetic acid, stir and mix, and collect the reaction solution;

[0057] The reaction solution was added to the composite solution, stirred and mixed, and then placed at 55° C. for aging for 24 hours, and the titanium dioxide sol solution was collected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com