Method for recycling lithium from waste lithium battery positive electrode material, recycled material and recycling system

A technology for waste lithium batteries and positive electrode materials, which is applied in the field of materials and recycling systems, can solve the problems of low recovery rate, achieve simple process flow, easy control of process conditions, and reduce recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

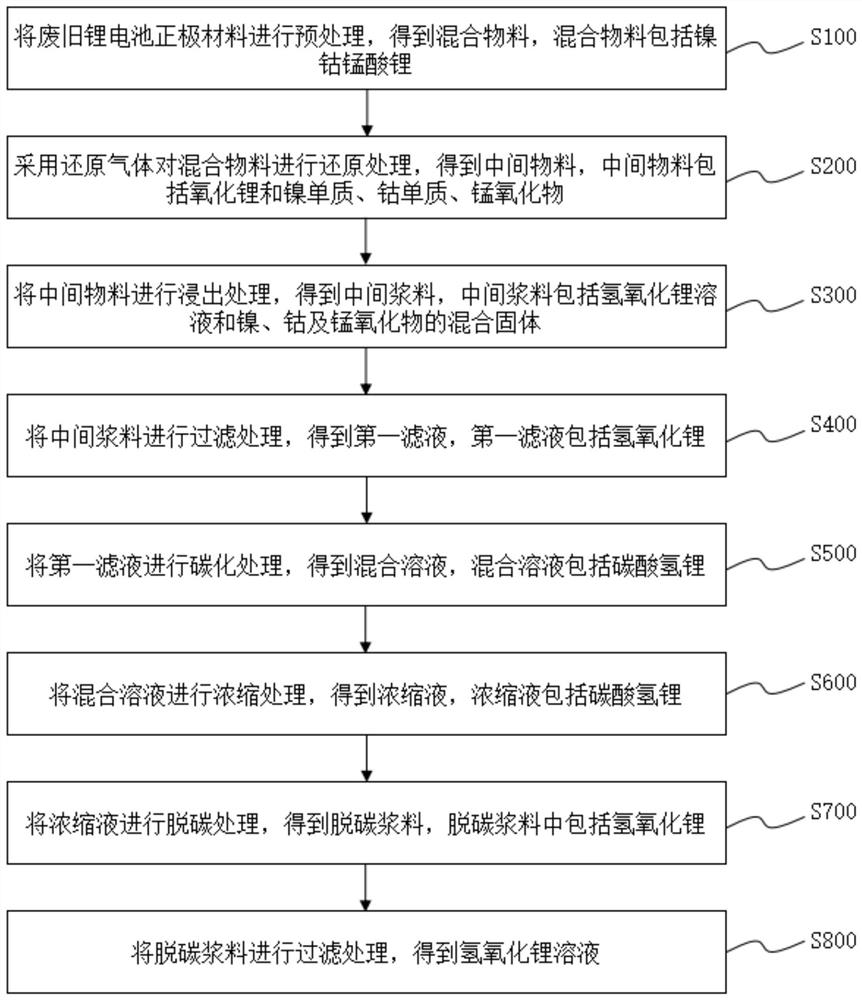

Method used

Image

Examples

Embodiment 1

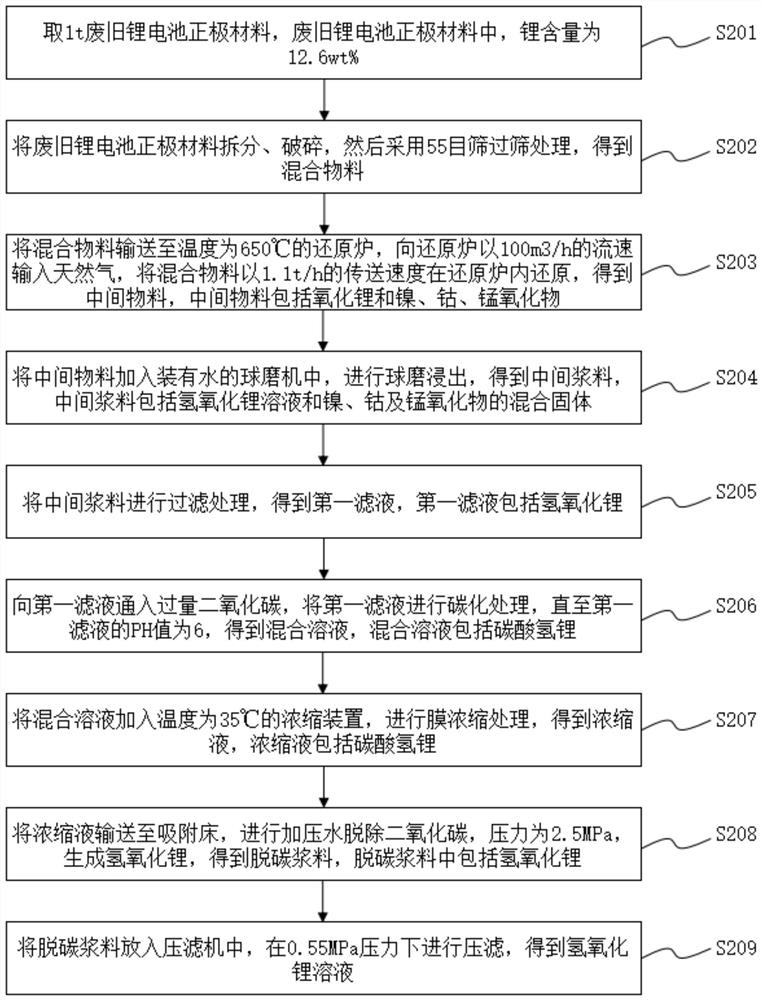

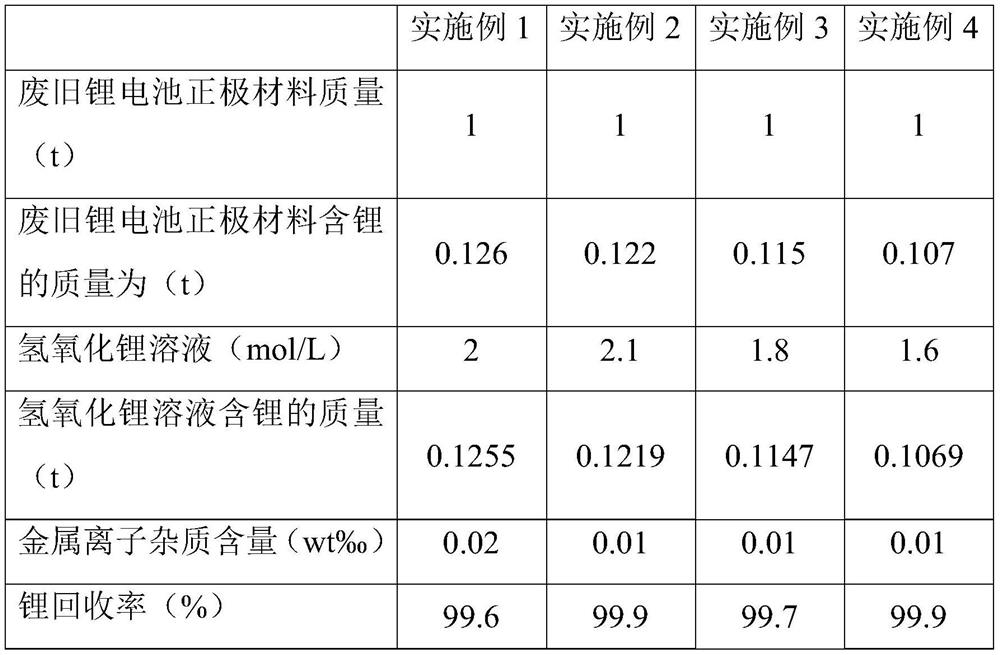

[0114] The method for recovering lithium from the positive electrode material of waste lithium batteries in this embodiment includes the following steps:

[0115] S201: Take 1 t of waste lithium battery positive electrode material, and the lithium content in the waste lithium battery positive electrode material is 12.6 wt %.

[0116] S202: splitting and crushing the positive electrode material of the waste lithium battery, and then sieving through a 55-mesh sieve to obtain a mixed material.

[0117] S203: The mixed material is transported to a reduction furnace with a temperature of 650° C. to the reduction furnace by 100 m 3 The natural gas is input at a flow rate of / h, and the mixed material is reduced in a reduction furnace at a conveying speed of 1.1t / h to obtain an intermediate material, which includes lithium oxide and oxides of nickel, cobalt, and manganese.

[0118] S204 : adding the intermediate material into a ball mill equipped with water, and performing ball mill...

Embodiment 2

[0125] The method for recovering lithium from the positive electrode material of waste lithium batteries in this embodiment includes the following steps:

[0126] S301: Take 1 t of waste lithium battery positive electrode material, and the lithium content in the waste lithium battery positive electrode material is 12.2 wt %.

[0127] S302: Splitting and crushing the positive electrode material of the waste lithium battery, and then sieving through a 75-mesh sieve to obtain a mixed material.

[0128] S303: Transport the mixed material to a reduction furnace with a temperature of 500° C. 3 The natural gas is input at a flow rate of / h, and the mixed material is reduced in a reduction furnace at a conveying speed of 1.0t / h to obtain an intermediate material, which includes lithium oxide and oxides of nickel, cobalt, and manganese.

[0129] S304 : adding the intermediate material into a ball mill equipped with water, and performing ball milling and leaching to obtain an intermedi...

Embodiment 3

[0136] The method for recovering lithium from the positive electrode material of waste lithium batteries in this embodiment includes the following steps:

[0137] S401: Take 1 t of waste lithium battery positive electrode material, and the lithium content in the waste lithium battery positive electrode material is 11.5 wt %.

[0138] S402: Splitting and crushing the positive electrode material of the waste lithium battery, and then sieving through a 60-mesh sieve to obtain a mixed material.

[0139] S403: The mixed material is transported to a reduction furnace with a temperature of 800° C. to the reduction furnace at 130 m 3 The natural gas is input at a flow rate of / h, and the mixed material is reduced in a reduction furnace at a conveying speed of 0.9t / h to obtain an intermediate material, which includes lithium oxide and oxides of nickel, cobalt, and manganese.

[0140] S404 : adding the intermediate material into a ball mill equipped with water, and performing ball mill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com