Method for synthesizing anatase titanium dioxide based on eutectic solvent

A low eutectic solvent, titanium dioxide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of difficult removal of surfactants, complex synthesis of ionic liquids, and poor environmental friendliness, etc. Achieving the effect of uniform shape, size and space distribution, environment-friendly synthesis and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] The specific embodiment of the present invention includes the following steps:

[0027] S1. Disperse the titanium precursor in the first absolute ethanol to form A solution;

[0028] S2, mixing deep eutectic solvent with halogen compound, second absolute ethanol, deionized water and nitric acid to form B solution;

[0029] S3, dropping the B solution obtained in step S2 into the A solution obtained in step S1, and obtaining titanium dioxide white gel after aging;

[0030] S4, drying the titanium dioxide white gel obtained in step S3 to obtain titanium dioxide particles;

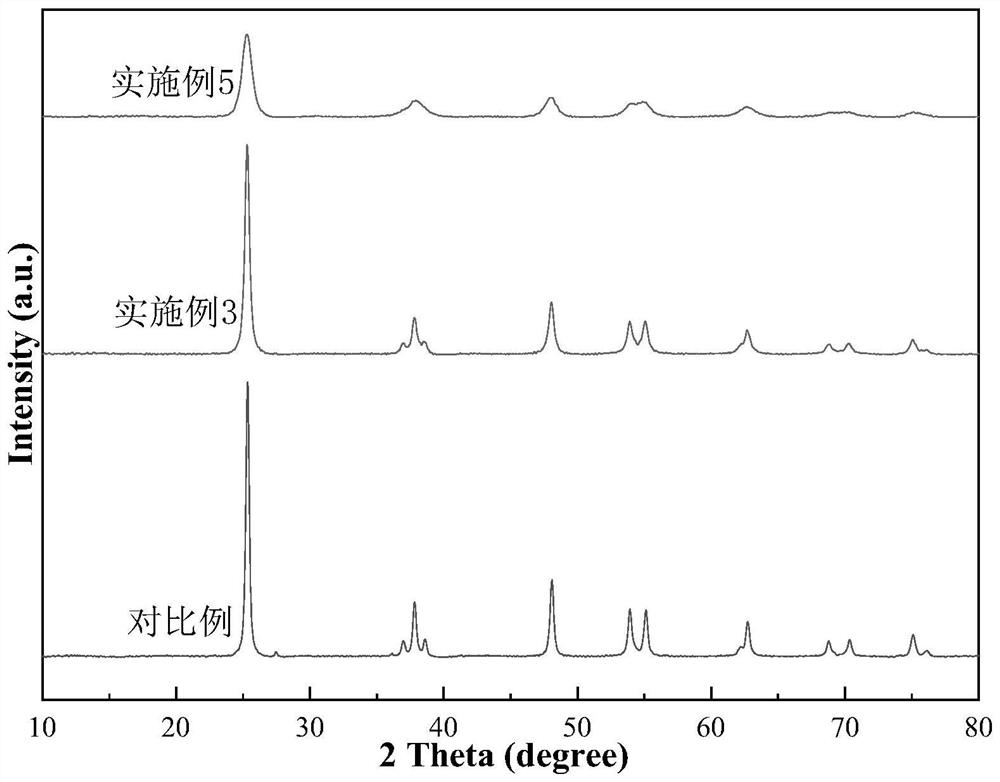

[0031] S5. The above-mentioned dried titanium dioxide particles are ground and then calcined to obtain anatase titanium dioxide.

[0032] Wherein, in step S1, the precursor of titanium is tetrabutyl titanate.

[0033] Wherein, in step S1, in molar ratio, the precursor of titanium: the first absolute ethanol=1: (20-28).

[0034] Wherein, in step S2, the deep eutectic solvent is a combination of a hy...

Embodiment 1

[0044] S1. Disperse 1.7 mL of tetrabutyl titanate in 6.8 mL of absolute ethanol to form A solution;

[0045] S2. Mix the deep eutectic solvent with 2.34 g of sodium chloride, 1.7 mL of absolute ethanol, 1.7 mL of deionized water and 0.01 mL of nitric acid to form solution B; wherein the molar ratio of the deep eutectic solvent to tetrabutyl titanate is 2:1, the preparation method of the deep eutectic solvent is as follows: choline chloride and ethylene glycol are mixed according to a molar ratio of 1:2, then, heated to 60 ° C, and stirred for 2h;

[0046] S3. B solution was added dropwise to A solution at a rate of 3 mL / min, and a white gel was obtained after aging for 3 h;

[0047] S4. Dry the white titanium dioxide gel in an oven at 80°C for 24 hours; obtain titanium dioxide particles;

[0048] S5. After grinding the dried titanium dioxide particles, put them into a muffle furnace and calcinate at 400° C. for 2 hours to obtain anatase titanium dioxide.

Embodiment 2

[0050] S1. Disperse 1.7 mL of tetrabutyl titanate in 6.8 mL of absolute ethanol to form A solution;

[0051] S2. Mix the deep eutectic solvent with 4.12 g of sodium bromide, 1.7 mL of absolute ethanol, 1.7 mL of deionized water and 0.01 mL of nitric acid to form solution B; wherein the molar ratio of the deep eutectic solvent to tetrabutyl titanate is 3:1, the preparation method of the deep eutectic solvent is as follows: tetrabutylammonium bromide and ethylene glycol are mixed according to a molar ratio of 1:2, then, heated to 60 ° C, and stirred for 2h;

[0052] S3. B solution was added dropwise to A solution at a rate of 3 mL / min, and a white gel was obtained after aging for 3 h;

[0053] S4. Dry the white titanium dioxide gel in an oven at 80°C for 24 hours; obtain titanium dioxide particles;

[0054]S5. After grinding the dried titanium dioxide particles, put them into a muffle furnace and calcinate at 400° C. for 2 hours to obtain anatase titanium dioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com