Magnesium-zinc alloy biliary stent and preparation method thereof

An alloy, magnesium-zinc technology, applied in the field of magnesium-zinc alloy biliary stent and preparation, can solve problems such as low strength and limited support force, and achieve the effects of good corrosion resistance, good forming ability, and good radial support force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

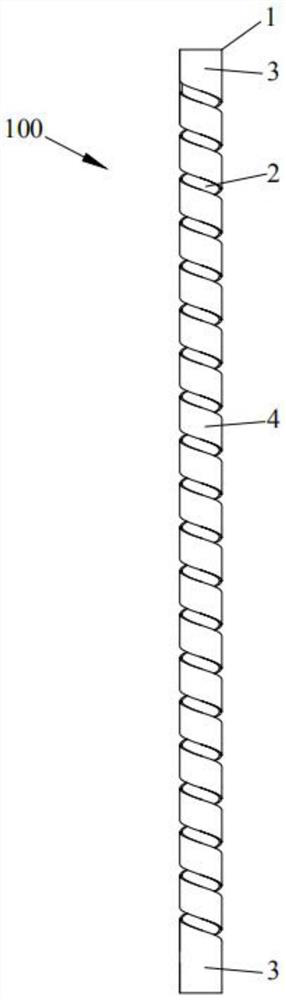

[0032] like Figure 1-Figure 2 As shown, the present embodiment provides a method for preparing a magnesium-zinc alloy biliary stent, comprising the following steps:

[0033] S1: Select magnesium-zinc alloy casting billet, wherein the mass fraction of Zn is 1.8%-2.2%, and the balance is Mg;

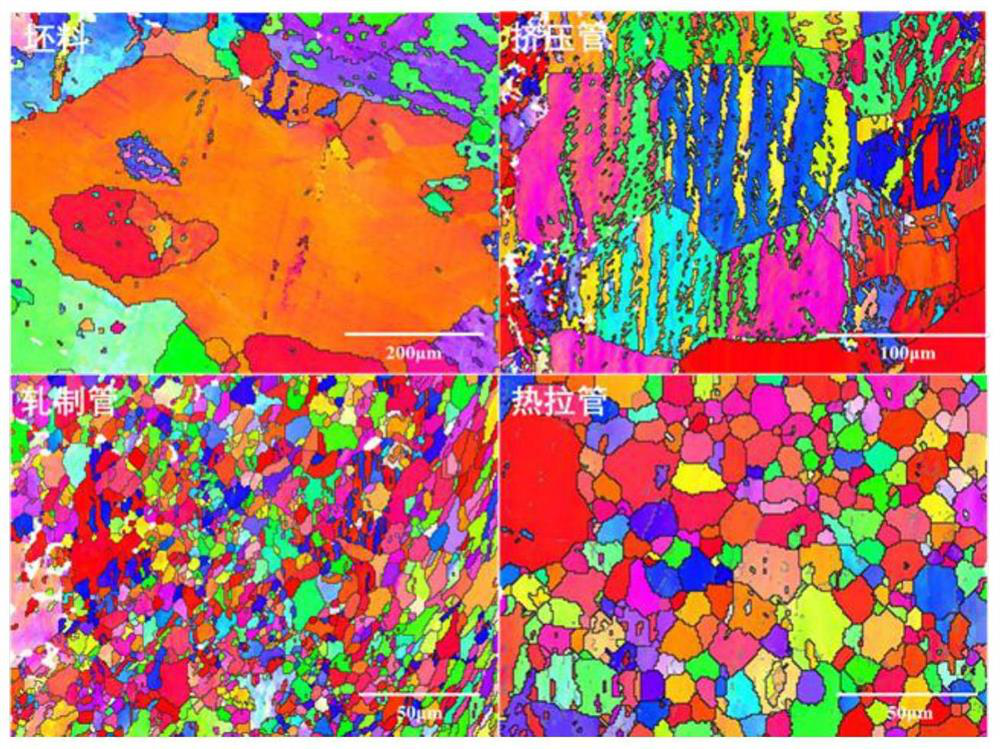

[0034] S2: heating the magnesium-zinc alloy casting billet to 330°C-350°C, and performing single-pass extrusion at 330°C-350°C, with an extrusion ratio of 70-100, to obtain an extruded pipe;

[0035] S3: The extruded pipe is subjected to multiple passes of room temperature rolling deformation, wherein the deformation amount of a single pass is 5%-10%, and annealing is carried out at 200 ℃-250 ℃ after each pass of rolling, so as to obtain a human bile duct implantation. size of rolled pipe;

[0036] S4: hot-drawing the rolled pipe at 230°C-260°C to obtain a magnesium-zinc alloy pipe with a smooth surface and a uniform microstructure;

[0037] S5: The spiral groove 2 is processed on the ...

Embodiment 1

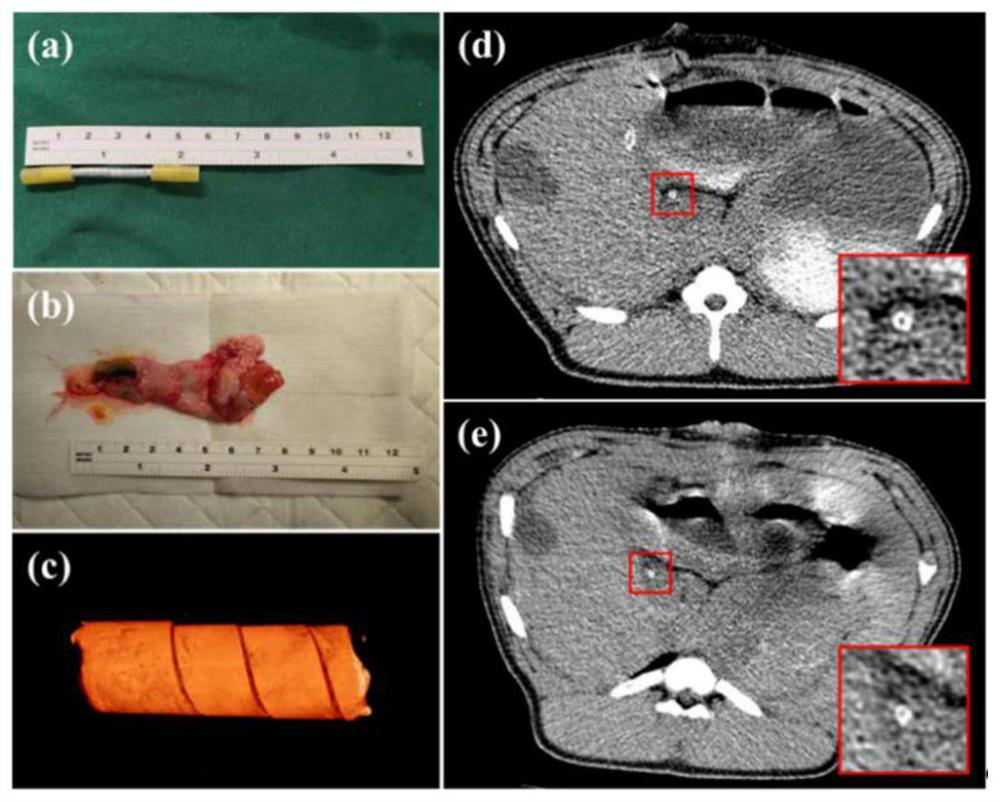

[0058] The magnesium-zinc alloy pipe with Zn content of 2% is selected, the outer diameter of the magnesium-zinc alloy pipe is less than 2.6mm, and the wall thickness is less than 0.18mm. The above-mentioned magnesium-zinc pipe is laser-cut to form a helical support portion 4 with a helical structure and annular support portions 3 at both ends, wherein the width of the helical groove is 0.2 mm and the pitch is 1.5 mm. After the biliary stent was implanted into the pig common bile duct with the cooperation of the endoscopic retrograde cholangiopancreatography (ERCP) system, the stent remained in the bile duct for 30 days, and the biliary stent was completely discharged after 40 days. Biosafety is good.

Embodiment 2

[0060] Select a magnesium-zinc alloy casting billet with a Zn content of 2%; heat the billet to a set temperature of 330 °C, and perform single-pass extrusion at 330 °C, with an extrusion ratio of 80; and then pass through multiple passes at 20 °C 10% deformation, annealed at 230°C for 5 minutes after each single pass, and the obtained rolled tube was hot drawn at 250°C to obtain a final tube with an outer diameter of 2.5mm and a wall thickness of 0.15mm . The room temperature yield strength of the magnesium-zinc alloy pipe is 175MPa, and the tensile strength is 238MPa. The biliary stent was cut out of the above magnesium-zinc alloy tube by laser, and the biliary stent was implanted into the pig common bile duct with the cooperation of the endoscopic retrograde cholangiopancreatography (ERCP) system, and the stent was maintained in the bile duct for 30 days. Completely drained. Biosafety is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com