Purification method of circulating hydrogen for polycrystalline silicon

A purification method and polysilicon technology, applied in chemical instruments and methods, hydrogen, hydrogen separation, etc., can solve the problems of expensive palladium metal, low energy consumption of processing capacity, high production cost, reduce energy consumption, improve adsorption efficiency, improve The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A method for purifying circulating hydrogen for polycrystalline silicon, comprising the following operating procedures:

[0055] S1: Pre-purify the hydrogen in the circulating hydrogen storage tank;

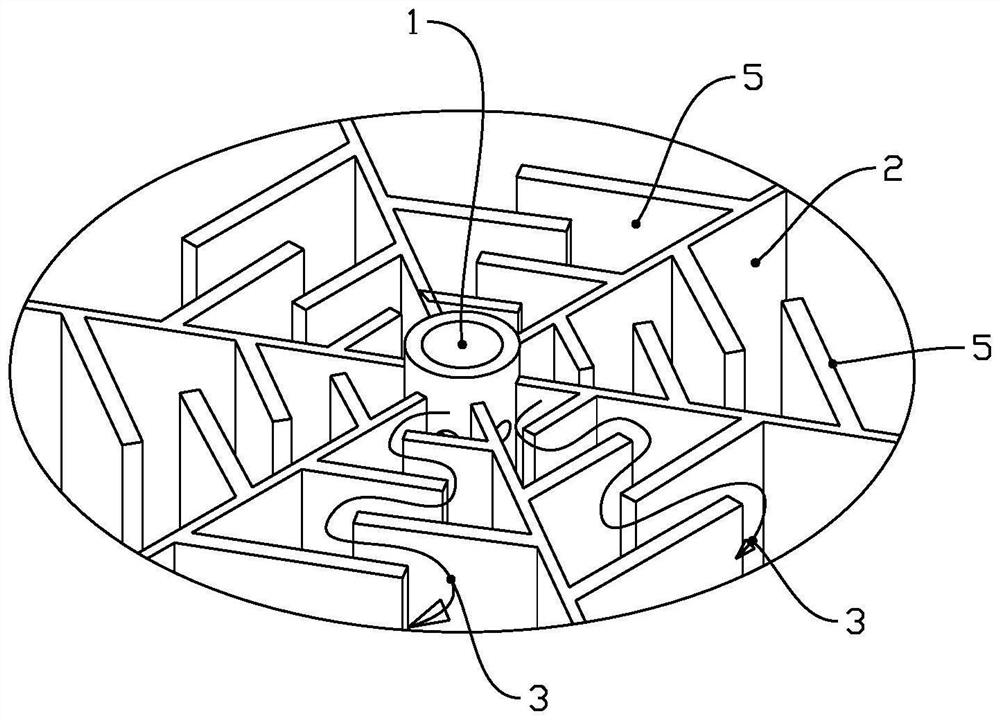

[0056] S2: The pre-purified hydrogen that has undergone pre-purification treatment is introduced into the purification device, and under the guidance of the purification device, flows into the selective hydrogen absorbing material along the first direction, and is located in two planes perpendicular to the first direction in the selective hydrogen absorbing material It flows between the two, and flows out of the purification device after passing through the selective hydrogen absorption material;

[0057] In this embodiment, it is preferable that the pre-purified hydrogen passes through the set transition position to realize the transition in the first direction, and the circulation path in the selective hydrogen absorption material after the transition is a straight line ...

Embodiment 1

[0086] Polysilicon production process, its typical tail gas composition is hydrogen, nitrogen, oxygen, hydrogen chloride, trichlorosilane, silicon tetrachloride and trace methane, etc., wherein the hydrogen content is 15-25% (v / v);

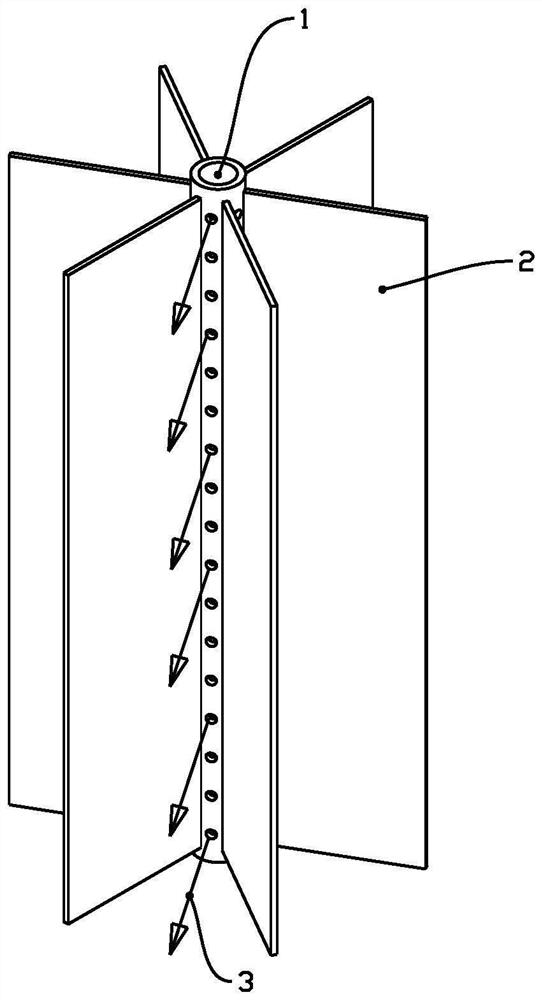

[0087] In this embodiment, the pre-purified hydrogen is figure 1 The form of flow along a straight line as shown flows outward in the selective hydrogen absorption material; wherein the diameter of the purification device shell is φ=3m, the effective height is H=8m, and the space filling rate of the hydrogen absorption material in the purification device is 65%; And the selective hydrogen absorption material is AB 5 type hydrogen absorbing alloy LaNi 5 ; Among them, the metal hydride hydrogen storage material is a curd-shaped structure; the diameter of the curd-shaped structure is 15 μm, and the specific surface area is 400 m 2 / g, with a pore volume of 0.6 cm 3 g -1 , the curd-like structure is prepared by surfactant, with high specific surf...

Embodiment 2

[0092] Polysilicon production process, its typical tail gas composition is hydrogen, nitrogen, oxygen, hydrogen chloride, trichlorosilane, silicon tetrachloride and trace methane, etc., wherein the hydrogen content is 15-25% (v / v);

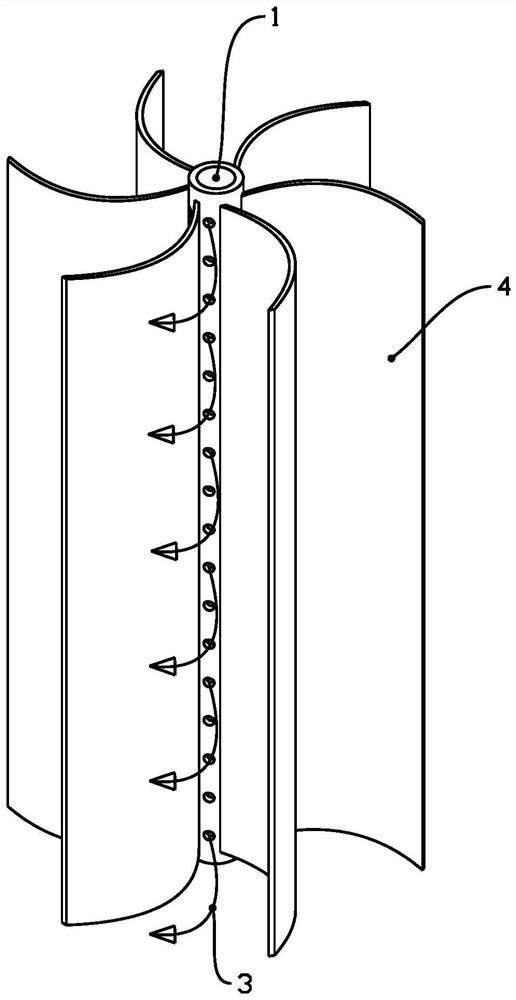

[0093] In this example, under the condition that the size of the purification device is the same as that in Example 1, the pre-purified hydrogen is figure 2 The shown form of flow along the curve flows outward in the selective hydrogen absorption material; here it is clear that the flow path of the arc-shaped curve is greater than the flow length of the straight flow;

[0094] The remaining structures and steps are similar to those in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com