Catalyst for preparing low-carbon alcohol through carbon dioxide conversion as well as preparation method and application of catalyst

A carbon dioxide and catalyst technology, which is applied to the catalyst for converting carbon dioxide to prepare low-carbon alcohols and the field of preparation thereof, can solve the problems of low ethanol selectivity, complicated preparation process, high price and the like, and achieve the effects of cost avoidance, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

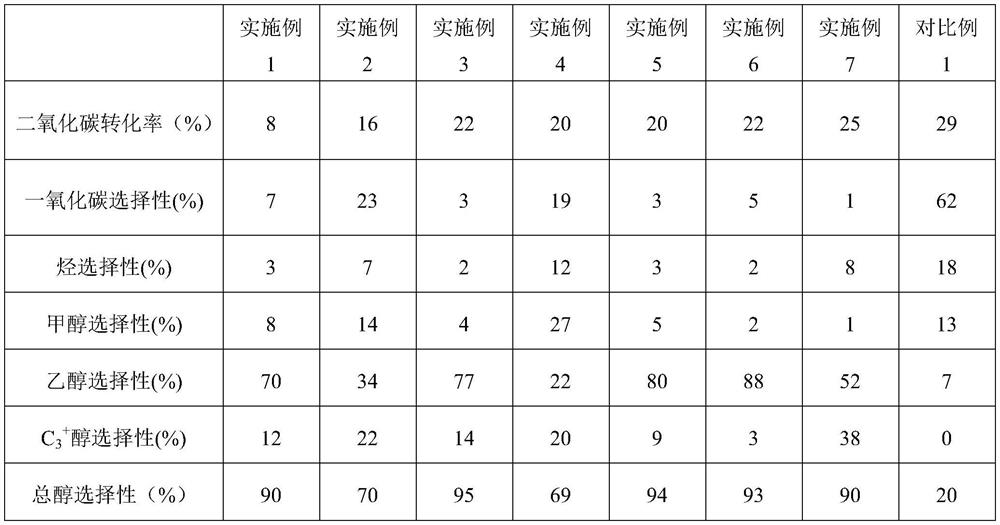

Examples

Embodiment 1

[0029] A preparation method of carbon dioxide conversion to prepare a low-carbon alcohol catalyst, the steps are as follows:

[0030] (1) 0.5g Co, 0.5g Co 3 O 4 and 9g Al 2 O 3 mix, get a mixture;

[0031] (2) the obtained mixture and 250g corundum grinding balls in step (1) are placed in the corundum grinding jar of 500 mL, and nitrogen is introduced into the grinding jar to replace the air; the grinding jar is put into the planetary ball mill for grinding; ball milling is set The conditions are: alternately rotate clockwise and counterclockwise every 1h, the speed is 100r / min, and the ball is milled for 70h; after the ball milling, the mixture is taken out;

[0032] (3) The mixture after ball milling in step (2) is placed in nitrogen at 500° C. for heat treatment for 5 hours; after the heat treatment is completed, the catalyst product is obtained.

[0033] Catalyst performance testing was performed in a slurry bed reactor.

Embodiment 2

[0035] A preparation method of carbon dioxide conversion to prepare a low-carbon alcohol catalyst, the steps are as follows:

[0036] (1) 2g Co, 1g Co(OH) 2 and 7g MoO 3 mix, get a mixture;

[0037] (2) mix the mixture obtained in step (1) and 250g ZrO 2 The grinding ball is placed in a 500mL zirconia grinding jar, and nitrogen is introduced into the grinding jar to replace the air; the grinding jar is put into a planetary ball mill for grinding; the conditions for ball milling are set as follows: clockwise and counterclockwise every 1h The directions are alternately rotated, the speed is 800r / min, and the ball is milled for 24h; after the ball milling, the mixture is taken out;

[0038] (3) The mixture after ball milling in step (2) is placed in argon at 800° C. for heat treatment for 1 hour; after the heat treatment is completed, the catalyst product is obtained.

[0039] Catalyst performance testing was performed in a fixed bed reactor.

Embodiment 3

[0041] A preparation method of carbon dioxide conversion to prepare a low-carbon alcohol catalyst, the steps are as follows:

[0042] (1) 4g Co, 4g CoO and 2g MnO are mixed to obtain mixture;

[0043] (2) in the step (1), the obtained mixture and 250g corundum grinding balls are placed in the nylon grinding tank of 500 mL, and nitrogen is introduced into the grinding tank to replace the air; the grinding tank is put into the drum ball mill and ground; set The conditions of ball milling are: alternately rotate clockwise and counterclockwise every 1h, the rotation speed is 200r / min, and the ball milling is 50h; after the ball milling, the mixture is taken out;

[0044] (3) The mixture after ball milling in step (2) is placed in carbon monoxide at 500° C. for heat treatment for 3 hours; after the heat treatment is completed, a catalyst product is obtained.

[0045] Catalyst performance testing was performed in a slurry bed reactor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com