Polyurethane for bearing, preparation method of polyurethane and polyurethane bearing

A polyurethane prepolymer, polyurethane technology, applied in the cantilever mounted on the pivot, transportation and packaging, rolling resistance optimization, etc., can solve the problems of shortened bearing service life, collision damage between the bearing body and the thrust rod, etc. Improve friction, not easy to hydrolyze and soften, and not easy to be worn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0046]S1, 50kg polycaprolactone diol, 70kg isophorone diisocyanate and 375kg tetrahydrofuran are mixed and heated to 45 ℃, and the reaction obtains a prepolymerized mixture;

[0047] S2, drop 0.1kg of dibutyltin dilaurate into the prepolymer mixture, heat to 60°C, and react at a constant temperature to obtain the prepolymer;

[0048] S3, add 6kg 1,4-butanediol to the prepolymer, and the reaction finishes to obtain a polyurethane prepolymer;

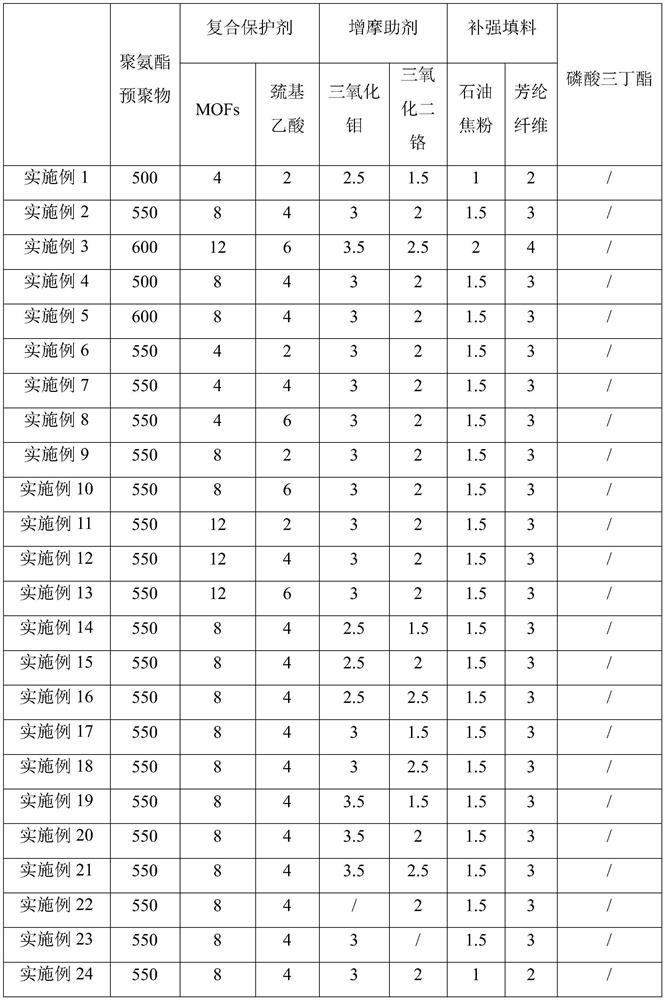

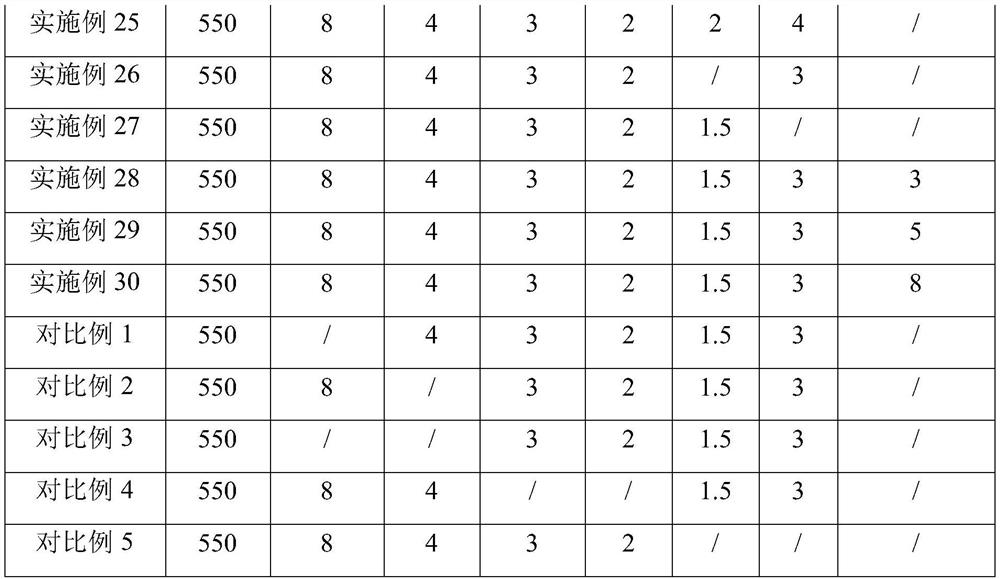

Embodiment 1

[0051] S1, the polyurethane prepolymer that 500kg above-mentioned preparation example makes, 1kg petroleum coke powder, 2kg aramid fiber, 2.5kg molybdenum trioxide and 1.5kg two chromium oxides are mixed and heated to 45 ℃, and constant temperature reaction obtains mixed material ;

[0052] S2, put 4kg MOFs into 2kg thioglycolic acid, mix evenly, dry and grind to obtain a composite protective agent, add the composite protective agent to the mixed material and mix evenly, dry and characterize, to obtain polyurethane for bearings.

Embodiment 2

[0054] S1, the polyurethane prepolymer that 550kg above-mentioned preparation example makes, 1.5kg petroleum coke powder, 3kg aramid fiber, 3kg molybdenum trioxide and 2kg two chromium oxides are mixed and heated to 45 ℃, and constant temperature reaction obtains mixed material;

[0055] S2, put 8kg MOFs into 4kg thioglycolic acid, mix evenly, dry and grind to obtain a composite protective agent, add the composite protective agent to the mixed material and mix evenly, dry and characterize, to obtain polyurethane for bearings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com