Mg-Ba series magnesium alloy and preparation method and application thereof

A magnesium alloy, mg-ba technology, applied in prosthesis, surgery, medical science, etc., can solve the problems of unclear metabolism/excretion, excessive corrosion, hidden dangers in medical applications, etc., to improve development and safety. performance, and the effect of optimizing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Pure Mg (99.98 wt. %) and pure Ba (99.9 wt. %) raw materials (pure metal / master alloy) were weighed in proportion, and smelted in an induction furnace after mixing sufficiently. After vacuuming (-2 Pa), filled with high-purity argon gas as a protective atmosphere, smelted at 800 ° C, applied electromagnetic stirring or mechanical stirring to the melt, after holding for 30 minutes, the uniform melt was introduced into two counter-rotating rolls, and the cooling process In the process, simultaneous casting and rolling are achieved to obtain pre-deformed Mg-Ba alloys with different alloy compositions, including: Mg-0.2Ba, Mg-0.5Ba, Mg-1.0Ba, Mg-2.0Ba, Mg-10Ba.

Embodiment 2

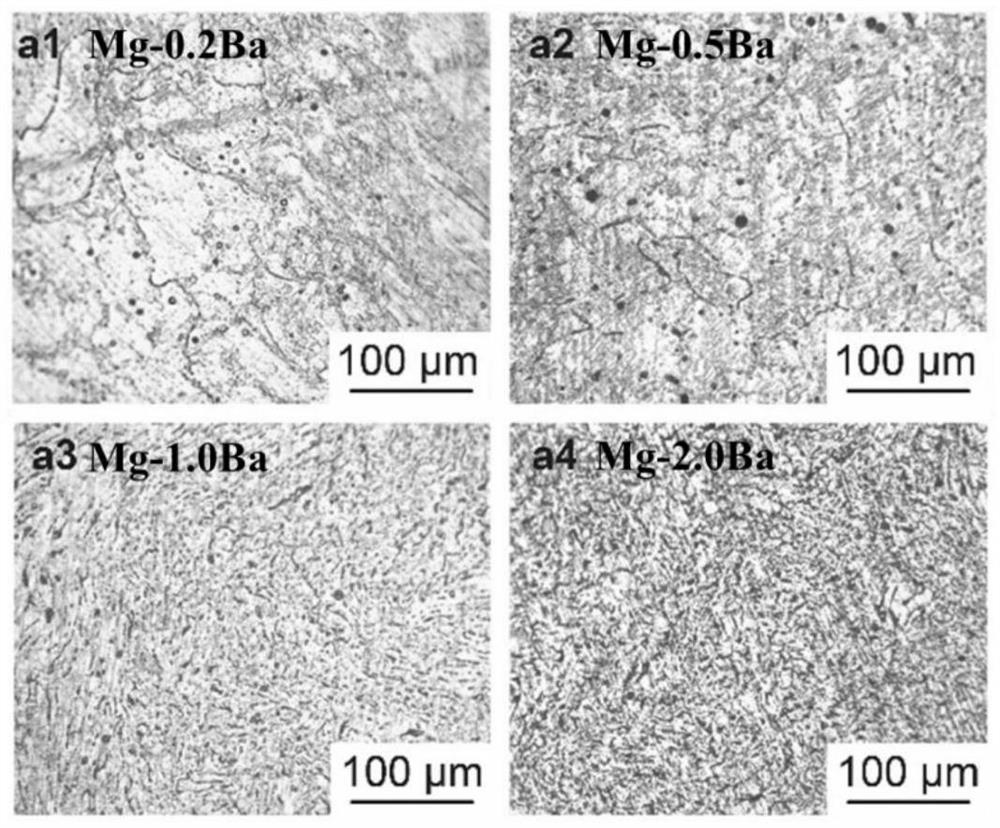

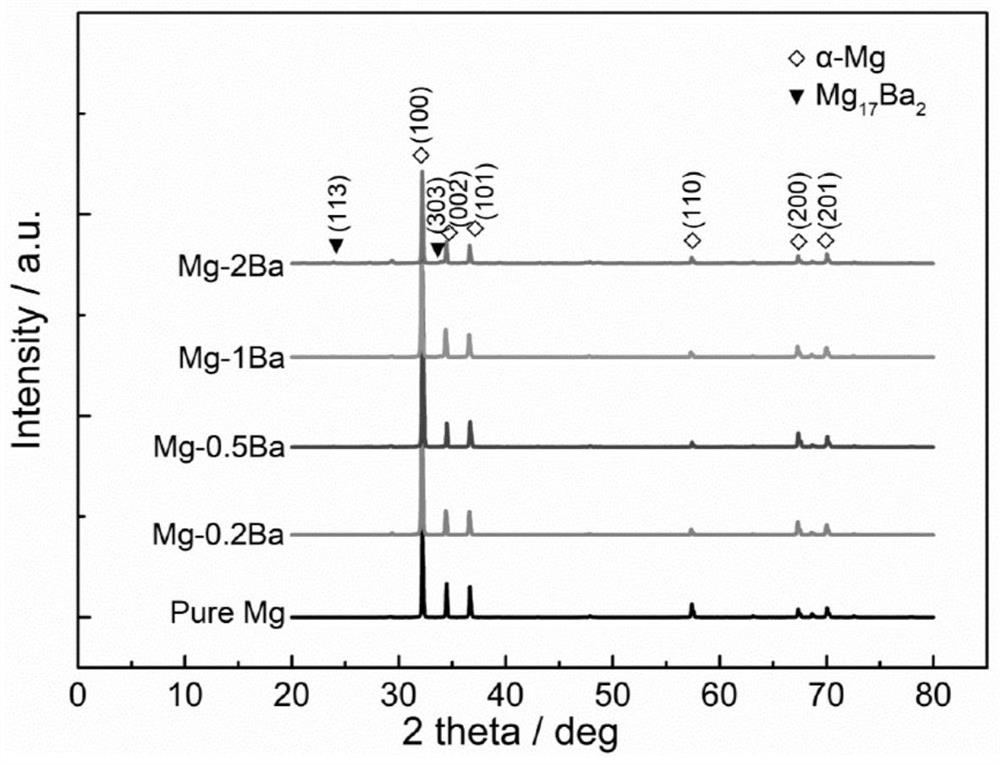

[0055] Referring to the method described in Example 1, smelting at 750-900°C, synchronous casting and rolling, Mg-0.2Ba, Mg-0.5Ba, Mg-1.0Ba and Mg-2.0Ba pre-deformed alloys were obtained. The pre-deformed alloy was homogenized at 400°C for 10 hours, then air-cooled and extruded at equal diameter angles. The Bc path was adopted, the extrusion speed was controlled at 2 mm / s, the extrusion passes were 4 times, and the extrusion temperature was 300°C. After the equal-diameter angular extrusion treatment, the grains of the Mg-Ba alloy were further refined significantly, and the second phase particles were effectively broken ( figure 1 ). X-ray diffraction (XRD) results show that the second phase in the above Mg-Ba alloy is Mg 17 Ba 2 ( figure 2 ).

Embodiment 3

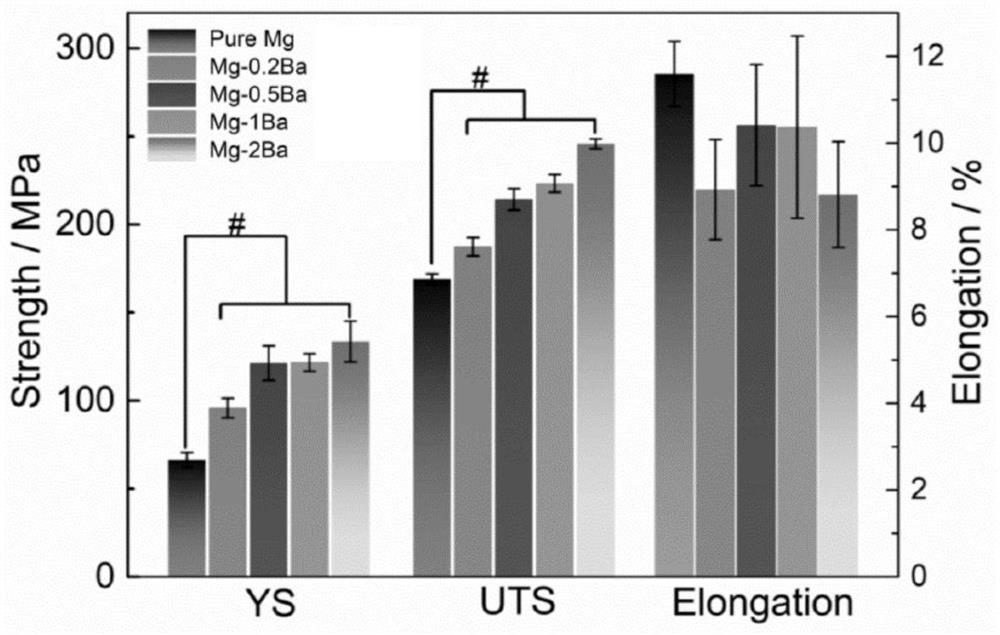

[0057] Referring to the method described in Example 1, a Mg-Ba series alloy was prepared. After the pre-deformed alloy was homogenized at 400 °C for 10 hours, it was extruded at 300-400 °C. The extrusion ratio was controlled to be 25, and the extrusion speed was 4 mm / s. It is extruded to a diameter of 10 mm one at a time to obtain a Mg-Ba binary alloy extruded rod. Room temperature tensile experiments were performed on the obtained Mg-Ba based alloys. It can be found that the addition of Ba significantly improves the tensile properties of magnesium alloys ( image 3 ). When the Ba content is 0.2wt.%, the yield strength (96±6MPa) of the corresponding alloy is still low. When the Ba content increases to 0.5wt.%, the yield strength (121±9MPa) increases by 26% compared with Mg-0.2Ba %. When the Ba content was further increased to 2.0 wt.%, the yield strength was further increased (134±9MPa). The change of tensile strength of as-extruded Mg-Ba alloy with Ba content is consisten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com