Preparation method of ZIF-8-doped high-corrosion-resistance micro-arc oxidation composite coating

A technology of ZIF-8 and micro-arc oxidation, which is applied in the direction of coating, anodic oxidation, surface reaction electrolytic coating, etc., can solve the problems of corrosion resistance influence, restrict the application of micro-arc oxidation coating, etc., and achieve the improvement of corrosion resistance , cost reduction, simple system components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

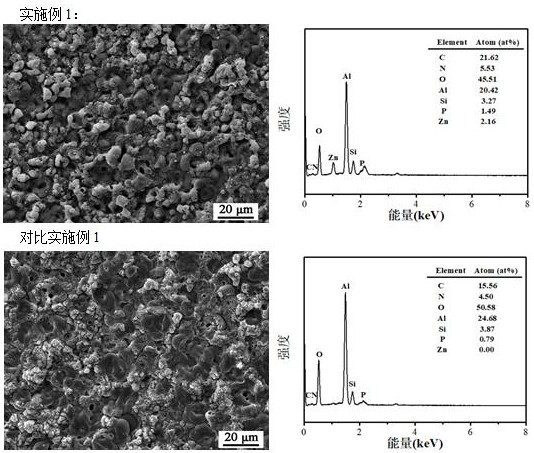

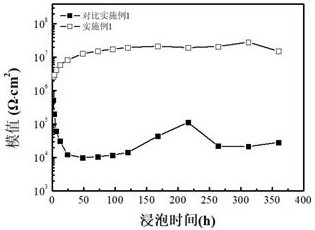

Embodiment 1

[0027] (1) Preparation of ZIF-8 particles: Dissolve dimethylimidazole and hexahydrate zinc nitrate in dimethylformamide in turn, then add ethylenetriamine, dimethylimidazole, hexahydrate zinc nitrate, dimethylformamide The molar ratio with ethylenetriamine is 1:1:8.36:0.044, the pH of the aforementioned solution is adjusted to 9.2 with a concentration of 10mol / L sodium hydroxide solution, and the white emulsion is obtained by ultrasonic stirring for 1h for 3h, and the stirring speed is 300 rpm, and centrifuged to obtain a white solid, which was washed alternately with methanol and deionized water for 4 times, and then vacuum-dried at 40 °C to obtain a white powdery ZIF-8 micron-sized material.

[0028] (2) Workpiece treatment: The micro-arc oxidation anode material is 6061 aluminum alloy, which is processed into a rectangular sample of 35mm × 30mm × 5mm, and the hole is drilled just above the top of the sample, and the diameter of the hole is 3mm. Grind the front and side of t...

Embodiment 2

[0038] (1) Preparation of ZIF-8 particles: Dissolve dimethylimidazole and hexahydrate zinc nitrate in dimethylformamide in turn, then add ethylenetriamine, dimethylimidazole, hexahydrate zinc nitrate, dimethylformamide The molar ratio of ethylenetriamine and ethylenetriamine is 3:1:8.36:0.044, the pH is adjusted to 9.2 with sodium hydroxide solution with a concentration of 10 mol / L, and the white emulsion is obtained by ultrasonic stirring for 1 h for 3 h. After centrifugation, a white emulsion is obtained. The solid was washed alternately with methanol and deionized water for 4 times, and then dried under vacuum at 50 °C to obtain a white powdery ZIF-8 micron material.

[0039] (2) Workpiece processing: refer to the method described in Example 1.

[0040] (3) Electrolyte configuration: put 1.5 L of deionized water in a 2 L container, add the ZIF-8 particles prepared in step (1) in an amount of 2 g / L, and use an ultrasonic device with a power of 25 W. 8 g / L of sodium silicate...

Embodiment 3

[0044] (1) Preparation of ZIF-8 particles: Dissolve dimethylimidazole and hexahydrate zinc nitrate in dimethylformamide in turn, then add ethylenetriamine, dimethylimidazole, hexahydrate zinc nitrate, dimethylformamide The molar ratio of ethylenetriamine and ethylenetriamine is 5:1:8.36:0.044, the pH of the sodium hydroxide solution with a concentration of 10 mol / L is adjusted to 9.2, and the white emulsion is obtained by ultrasonication for 1 h and 3 h, which is obtained by centrifugation. The white solid was washed alternately with methanol and deionized water for 4 times, and then dried under vacuum at 60 °C to obtain a white powdery ZIF-8 micron material.

[0045] (2) Workpiece processing: refer to the method described in Example 1.

[0046] (3) Electrolyte configuration: put 1.5 L of deionized water in a 2 L container, add the ZIF-8 particles prepared in step (1) in an amount of 1 g / L, and use an ultrasonic device with a power of 25 W. 5 g / L of sodium silicate nonahydrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com