Absorbable composite material and preparation method thereof

A technology for absorbing composite materials and manufacturing methods, which is applied in the field of absorbable composite materials and its preparation, can solve the problems of needing improvement in osteogenesis, fast degradation speed, and limited scope of application, so as to facilitate bone tissue repair, realize large-scale production, The effect of high overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

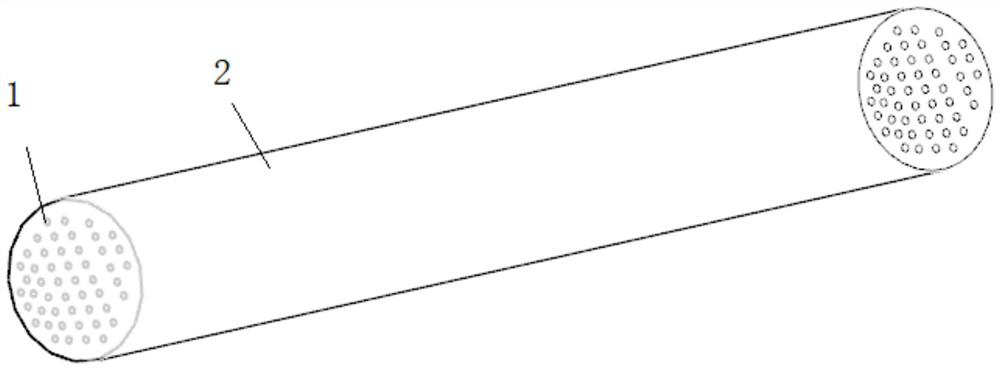

[0053] a. Preset absorbable magnesium-zinc alloy wire with a diameter of about 0.1mm into the mold, and arrange it in multiple layers, with a gap of about 1.0mm between each layer, of which the absorbable magnesium-zinc alloy wire accounts for the total volume of the composite material 5%.

[0054] b. Mix 1 part of bioceramic hydroxyapatite and 99 parts of polyglycolide, set the temperature of each section of the extruder equipment in the range of 60°C to 230°C, and carry out melting, mixing, shearing, dispersing and pulling. Elongate and cool the pellets to obtain uniformly dispersed pellets.

[0055] c. Filling with bioceramic hydroxyapatite powder and absorbable polyester material in the interval of absorbable magnesium-zinc alloy wire of each layer. The temperature of the hydraulic press was raised to 220°C, the mold with the wire was placed on the equipment, and the pellets prepared in b were placed on the mold. It is fully preheated, until it is completely melted, pres...

Embodiment 2

[0058] a. Preset absorbable magnesium-iron alloy wires with a diameter of about 1mm into the mold, interweave or arrange them in parallel, in one or more layers, with a gap of about 1.5mm between each layer, in which the absorbable magnesium-iron alloy wires account for the composite 18% of the total volume of the material. After the die is firmly connected to the extruder die, the die is preheated.

[0059] b. Mix the ratio of 15 parts of bioceramic tricalcium phosphate and 85 parts of polylactic acid, set the temperature of each section of the extruder equipment in the range of 60 ° C ~ 230 ° C, and perform melt extrusion, and the molten composite material passes through the die. Flow into a mold with wire to obtain a uniformly dispersed composite material. The obtained composite material is cooled and shaped into a rod, and after sufficient cooling, it is subjected to subsequent processing, and the final material is subjected to a mechanical test, the bending strength can ...

Embodiment 3

[0061] Preset absorbable magnesium-zirconium alloy wires with diameters less than 2mm in different thicknesses into the mold and arrange them in parallel with a gap of about 1.5mm between the layers, of which the absorbable magnesium-zirconium alloy wires account for 32% of the total volume of the composite material. %. Put the used mold in the injection molding machine for preheating. The blend of 90 parts of polylactic acid, 5 parts of polyglycolide and 5 parts of hydroxyapatite powder is initially mixed and dispersed, and then granulated, and the temperature of each section of the extruder is controlled at 60-230°C. The pellets are then injected, and the temperature of each section of the injection molding machine is controlled at 190-230°C. The molten material is filled into the mold by injection molding. The composite material is obtained by cooling and setting. The obtained composite material can be stretched or extruded at a heating and non-melting temperature to enh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com