Preparation method of complex iron desulfurizer

A technology of desulfurization agent and complex iron, which is applied in the field of desulfurization, can solve the problems of low desulfurization rate, secondary salt, and low sulfur capacity of desulfurization liquid, and achieve high desulfurization rate, obvious separation effect, and reduce equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further explained below in conjunction with specific embodiments.

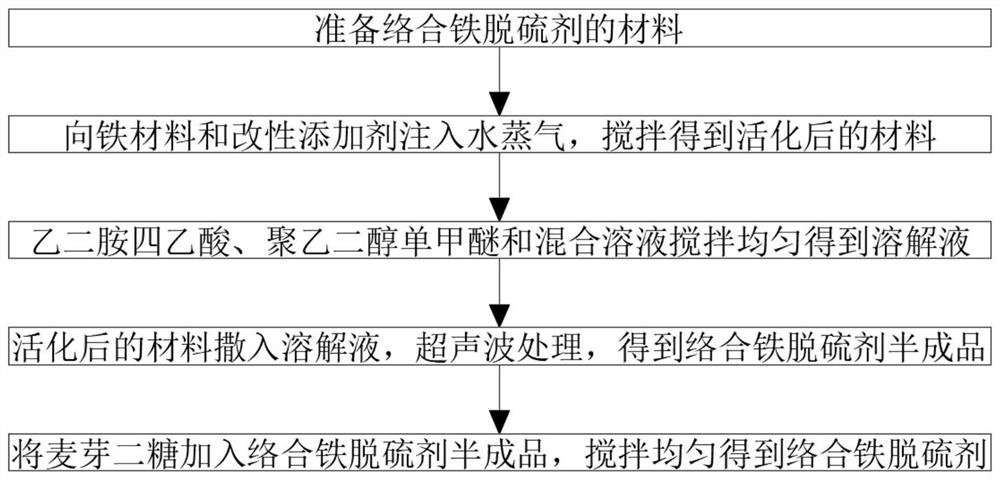

[0024] refer to figure 1 , Example 1

[0025] In the present embodiment, a preparation method of a complex iron desulfurizer is proposed, comprising the following steps:

[0026] S1: Prepare the material of the complex iron desulfurizer. The material of the complex iron desulfurizer includes 31 parts of iron material, 42 parts of ethylenediaminetetraacetic acid, 13 parts of maltobiose, and 8 parts of polyethylene glycol monomethyl. Ether, 79 parts of mixed solution and 8 parts of modified additive, mixed solution includes two kinds of soda ash, ammonia water and caustic soda, modified additive includes cobalt salt and molybdenum salt, iron material includes iron salt, elemental iron ion, trioxide When one or two of iron and other iron-containing compounds, soda ash and caustic soda are mixed with ammonia water, the added deionized water accounts for 40% to 60% of the mixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com