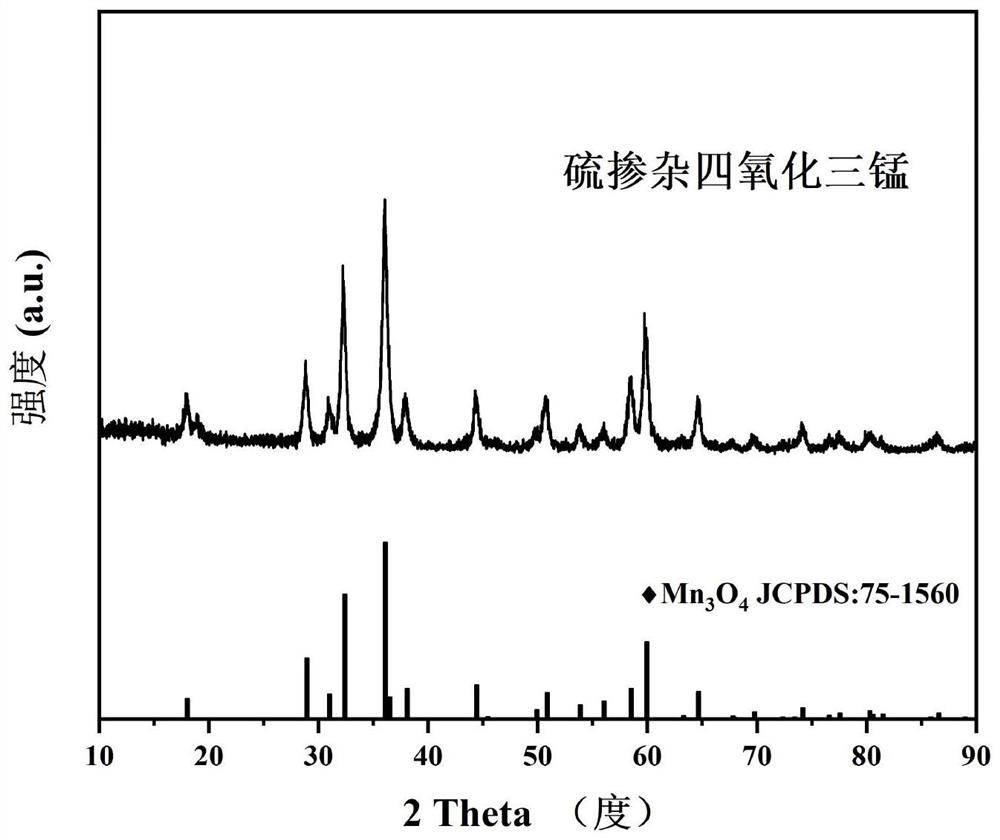

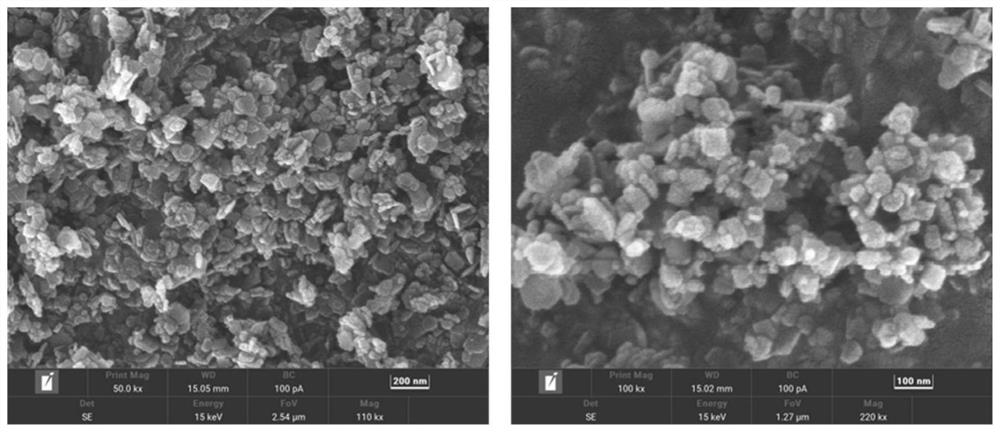

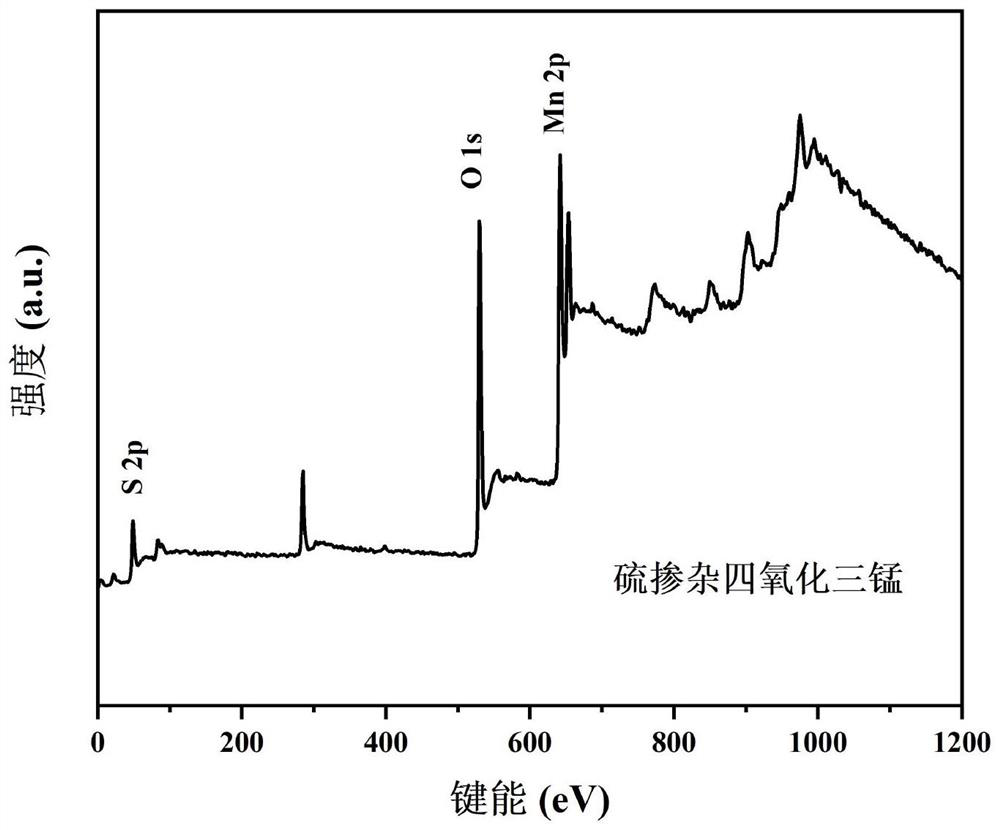

Sulfur-doped manganous-manganic oxide nano material as well as preparation method and application thereof

A nano-manganese tetraoxide and sulfur-doped technology, which is applied in the direction of manganese oxide/manganese hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of complex preparation and the performance of positive electrode materials that need to be improved, so as to achieve abundant material sources, Broad industrial application prospects and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1. Take 1.2677g MnSO 4 ·H 2 O and 2.4925g K 3 [Co Ⅲ (EN) 6 ] The powders were respectively dissolved in 30 mL of deionized water to obtain an aqueous solution of manganese sulfate and an aqueous solution of potassium cobalt cyanide. The manganese sulfate aqueous solution was added dropwise to the cobalt potassium cyanide aqueous solution. After the solution was added dropwise, stirring was continued for 2 h at room temperature. Then, the white precipitate was collected by suction filtration, washed three times with deionized water, and then placed in a vacuum drying oven for drying at 100° C. for 24 hours to obtain manganese-cobalt Prussian blue.

[0033] Step 2. Add 60 mg of the above manganese-cobalt Prussian blue to 60 mL of ethanol and ultrasonicate for 20 minutes to obtain a milky white suspension. 120mg Na 2 S·9H 2 O was dissolved in 30 mL of deionized water to obtain a sodium sulfide solution, and the sodium sulfide solution was slowly added to the ab...

Embodiment 2

[0039] Step 1. Take 1.2677g MnSO 4 ·H 2 O and 2.4925g K 3 [Co Ⅲ (EN) 6 ] The powders were respectively dissolved in 15 mL of deionized water to obtain an aqueous solution of manganese sulfate and an aqueous solution of potassium cobalt cyanide. The manganese sulfate aqueous solution was added dropwise to the cobalt potassium cyanide solution. After the solution was added dropwise, stirring was continued at room temperature for 2 hours. Then, the white precipitate was collected by suction filtration, washed three times with deionized water, and then placed in a vacuum drying oven for drying at 100° C. for 24 hours to obtain manganese-cobalt Prussian blue.

[0040] Step 2. Add 60 mg of the above manganese-cobalt Prussian blue to 60 mL of ethanol and ultrasonically for 20 minutes to obtain a milky white suspension. 120mg Na 2 S·9H 2 O was dissolved in 30 mL of deionized water to obtain a sodium sulfide solution. The sodium sulfide solution was slowly added to the above sus...

Embodiment 3

[0044] Step 1. Take 1.2677g MnSO 4 ·H 2 O and 2.4925g K 3 [Co Ⅲ (EN) 6 ] The powders were respectively dissolved in 10 mL of deionized water to obtain an aqueous solution of manganese sulfate and an aqueous solution of potassium cobalt cyanide. The manganese sulfide aqueous solution was added dropwise to the cobalt potassium cyanide aqueous solution. After the solution was added dropwise, stirring was continued for 2 h at room temperature. Finally, the white precipitate was collected by suction filtration, washed three times with deionized water, and then placed in a vacuum drying oven for drying at 100° C. for 24 hours to obtain manganese-cobalt Prussian blue.

[0045] Step 2. Add 60 mg of the above manganese-cobalt Prussian blue to 60 mL of ethanol and ultrasonicate for 20 minutes to obtain a milky white suspension. 120mg Na 2 S·9H 2 O was dissolved in 30 mL of deionized water to obtain a sodium sulfide solution. The sodium sulfide solution was slowly added to the abo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com